Filter News

Area of Research

- Advanced Manufacturing (5)

- Biological Systems (1)

- Biology and Environment (39)

- Clean Energy (140)

- Computational Biology (2)

- Computational Engineering (2)

- Computer Science (3)

- Energy Sciences (1)

- Fusion and Fission (12)

- Fusion Energy (7)

- Isotope Development and Production (1)

- Isotopes (11)

- Materials (59)

- Materials for Computing (9)

- Mathematics (1)

- National Security (23)

- Neutron Science (26)

- Nuclear Science and Technology (17)

- Nuclear Systems Modeling, Simulation and Validation (1)

- Quantum information Science (2)

- Supercomputing (38)

- Transportation Systems (2)

News Type

News Topics

- (-) Advanced Reactors (31)

- (-) Biomedical (59)

- (-) Clean Water (30)

- (-) Composites (28)

- (-) Cybersecurity (34)

- (-) Energy Storage (104)

- (-) Space Exploration (25)

- (-) Transportation (88)

- 3-D Printing/Advanced Manufacturing (119)

- Artificial Intelligence (98)

- Big Data (54)

- Bioenergy (90)

- Biology (100)

- Biotechnology (23)

- Buildings (58)

- Chemical Sciences (70)

- Climate Change (98)

- Computer Science (189)

- Coronavirus (45)

- Critical Materials (28)

- Decarbonization (78)

- Education (5)

- Element Discovery (1)

- Emergency (2)

- Environment (186)

- Exascale Computing (41)

- Fossil Energy (6)

- Frontier (42)

- Fusion (55)

- Grid (62)

- High-Performance Computing (90)

- Hydropower (11)

- Irradiation (2)

- Isotopes (54)

- ITER (7)

- Machine Learning (48)

- Materials (139)

- Materials Science (134)

- Mathematics (9)

- Mercury (12)

- Microelectronics (4)

- Microscopy (47)

- Molten Salt (9)

- Nanotechnology (54)

- National Security (68)

- Net Zero (13)

- Neutron Science (130)

- Nuclear Energy (102)

- Partnerships (51)

- Physics (59)

- Polymers (29)

- Quantum Computing (36)

- Quantum Science (69)

- Renewable Energy (2)

- Security (24)

- Simulation (49)

- Software (1)

- Statistics (3)

- Summit (59)

- Sustainable Energy (123)

- Transformational Challenge Reactor (7)

Media Contacts

Brittany Rodriguez never imagined she would pursue a science career at a Department of Energy national laboratory. However, after some encouraging words from her mother, input from key mentors at the University of Texas Rio Grande Valley, or UTRGV, and a lot of hard work, Rodriguez landed at DOE’s Manufacturing Demonstration Facility, or MDF, at Oak Ridge National Laboratory.

To better predict long-term flooding risk, scientists at the Department of Energy’s Oak Ridge National Laboratory developed a 3D modeling framework that captures the complex dynamics of water as it flows across the landscape. The framework seeks to provide valuable insights into which communities are most vulnerable as the climate changes, and was developed for a project that’s assessing climate risk and mitigation pathways for an urban area along the Southeast Texas coast.

ORNL's Guang Yang and Andrew Westover have been selected to join the first cohort of DOE’s Advanced Research Projects Agency-Energy Inspiring Generations of New Innovators to Impact Technologies in Energy 2024 program. The program supports early career scientists and engineers in their work to convert disruptive ideas into impactful energy technologies.

Researchers at ORNL have successfully demonstrated the first 270-kW wireless power transfer to a light-duty electric vehicle. The demonstration used a Porsche Taycan and was conducted in collaboration with Volkswagen Group of America using the ORNL-developed polyphase wireless charging system.

Researchers at ORNL and the University of Maine have designed and 3D-printed a single-piece, recyclable natural-material floor panel tested to be strong enough to replace construction materials like steel.

ORNL scientists develop a sample holder that tumbles powdered photochemical materials within a neutron beamline — exposing more of the material to light for increased photo-activation and better photochemistry data capture.

Researchers set a new benchmark for future experiments making materials in space rather than for space. They discovered that many kinds of glass have similar atomic structure and arrangements and can successfully be made in space. Scientists from nine institutions in government, academia and industry participated in this 5-year study.

Researchers tackling national security challenges at ORNL are upholding an 80-year legacy of leadership in all things nuclear. Today, they’re developing the next generation of technologies that will help reduce global nuclear risk and enable safe, secure, peaceful use of nuclear materials, worldwide.

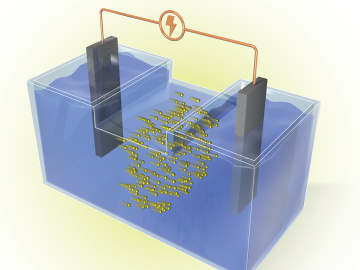

Researchers at ORNL are developing battery technologies to fight climate change in two ways, by expanding the use of renewable energy and capturing airborne carbon dioxide.

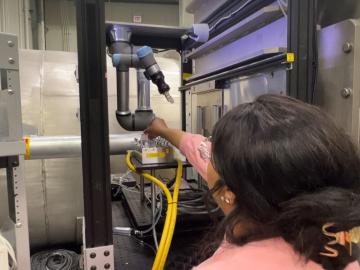

The BIO-SANS instrument, located at Oak Ridge National Laboratory’s High Flux Isotope Reactor, is the latest neutron scattering instrument to be retrofitted with state-of-the-art robotics and custom software. The sophisticated upgrade quadruples the number of samples the instrument can measure automatically and significantly reduces the need for human assistance.