Filter News

Area of Research

- (-) Biology and Environment (44)

- (-) Clean Energy (65)

- (-) Computational Engineering (1)

- (-) Computer Science (6)

- Advanced Manufacturing (5)

- Biology and Soft Matter (1)

- Building Technologies (2)

- Computational Biology (1)

- Energy Sciences (1)

- Fusion and Fission (6)

- Fusion Energy (2)

- Materials (22)

- Materials for Computing (4)

- National Security (9)

- Neutron Science (7)

- Quantum information Science (1)

- Supercomputing (29)

- Transportation Systems (1)

News Type

News Topics

- (-) Artificial Intelligence (13)

- (-) Composites (12)

- (-) Decarbonization (32)

- (-) Polymers (7)

- (-) Sustainable Energy (63)

- 3-D Printing/Advanced Manufacturing (46)

- Advanced Reactors (2)

- Big Data (12)

- Bioenergy (46)

- Biology (61)

- Biomedical (14)

- Biotechnology (10)

- Buildings (24)

- Chemical Sciences (7)

- Clean Water (18)

- Climate Change (44)

- Computer Science (37)

- Coronavirus (13)

- Critical Materials (4)

- Cybersecurity (5)

- Energy Storage (42)

- Environment (102)

- Exascale Computing (4)

- Fossil Energy (1)

- Frontier (3)

- Grid (30)

- High-Performance Computing (17)

- Hydropower (9)

- Machine Learning (12)

- Materials (19)

- Materials Science (15)

- Mathematics (5)

- Mercury (9)

- Microelectronics (1)

- Microscopy (11)

- Nanotechnology (5)

- National Security (3)

- Net Zero (3)

- Neutron Science (3)

- Nuclear Energy (3)

- Partnerships (4)

- Physics (1)

- Quantum Science (2)

- Renewable Energy (1)

- Security (3)

- Simulation (11)

- Space Exploration (3)

- Statistics (1)

- Summit (8)

- Transportation (44)

Media Contacts

Energy and sustainability experts from ORNL, industry, universities and the federal government recently identified key focus areas to meet the challenge of successfully decarbonizing the agriculture sector

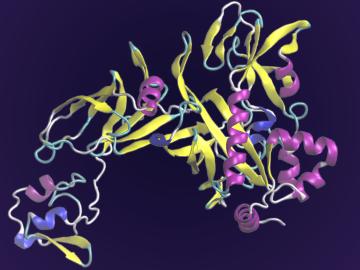

A team of scientists led by the Department of Energy’s Oak Ridge National Laboratory and the Georgia Institute of Technology is using supercomputing and revolutionary deep learning tools to predict the structures and roles of thousands of proteins with unknown functions.

An analysis by Oak Ridge National Laboratory shows that using less-profitable farmland to grow bioenergy crops such as switchgrass could fuel not only clean energy, but also gains in biodiversity.

Oak Ridge National Laboratory researchers determined that designing polymers specifically with upcycling in mind could reduce future plastic waste considerably and facilitate a circular economy where the material is used repeatedly.

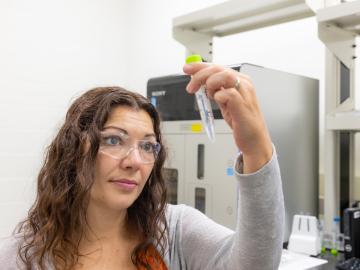

Carrie Eckert applies her skills as a synthetic biologist at ORNL to turn microorganisms into tiny factories that produce a variety of valuable fuels, chemicals and materials for the growing bioeconomy.

Oak Ridge National Laboratory researchers have developed a novel process to manufacture extreme heat resistant carbon-carbon composites. The performance of these materials will be tested in a U.S. Navy rocket that NASA will launch this fall.

Oak Ridge National Laboratory researchers developed and demonstrated algorithm-based controls for a hybrid electric bus that yielded up to 30% energy savings compared with existing controls.

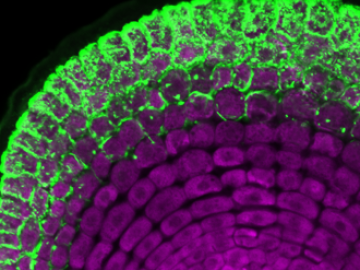

An ORNL team has successfully introduced a poplar gene into switchgrass, an important biofuel source, that allows switchgrass to interact with a beneficial fungus, ultimately boosting the grass’ growth and viability in changing environments.

For ORNL environmental scientist and lover of the outdoors John Field, work in ecosystem modeling is a profession with tangible impacts.

Oak Ridge National Laboratory researchers demonstrated that cooling cost savings could be achieved with a 3D printed concrete smart wall following a three-month field test.