Filter News

Area of Research

- Advanced Manufacturing (14)

- Biological Systems (2)

- Biology and Environment (52)

- Building Technologies (1)

- Clean Energy (75)

- Computational Engineering (1)

- Fusion and Fission (6)

- Fusion Energy (2)

- Isotopes (3)

- Materials (27)

- Materials for Computing (3)

- Mathematics (1)

- National Security (9)

- Neutron Science (11)

- Nuclear Science and Technology (9)

- Quantum information Science (1)

- Supercomputing (24)

News Type

News Topics

- (-) 3-D Printing/Advanced Manufacturing (70)

- (-) Bioenergy (67)

- (-) Clean Water (27)

- (-) Composites (15)

- (-) Critical Materials (14)

- (-) Frontier (25)

- (-) Molten Salt (6)

- (-) Security (12)

- (-) Space Exploration (22)

- Advanced Reactors (21)

- Artificial Intelligence (59)

- Big Data (41)

- Biology (77)

- Biomedical (39)

- Biotechnology (14)

- Buildings (38)

- Chemical Sciences (34)

- Climate Change (72)

- Computer Science (123)

- Coronavirus (28)

- Cybersecurity (17)

- Decarbonization (55)

- Education (1)

- Emergency (2)

- Energy Storage (60)

- Environment (147)

- Exascale Computing (26)

- Fossil Energy (5)

- Fusion (40)

- Grid (44)

- High-Performance Computing (55)

- Hydropower (11)

- Irradiation (2)

- Isotopes (32)

- ITER (5)

- Machine Learning (33)

- Materials (78)

- Materials Science (79)

- Mathematics (8)

- Mercury (10)

- Microelectronics (2)

- Microscopy (31)

- Nanotechnology (28)

- National Security (39)

- Net Zero (10)

- Neutron Science (74)

- Nuclear Energy (74)

- Partnerships (17)

- Physics (32)

- Polymers (17)

- Quantum Computing (24)

- Quantum Science (40)

- Renewable Energy (1)

- Simulation (38)

- Software (1)

- Statistics (2)

- Summit (36)

- Sustainable Energy (89)

- Transformational Challenge Reactor (3)

- Transportation (62)

Media Contacts

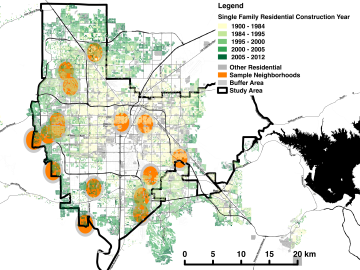

A team led by Oak Ridge National Laboratory has discovered that residents living in arid environments share a desire for water security, which can ultimately benefit entire neighborhoods. Las Vegas, Nevada’s water utility was the first utility in the United States to implement ...

The construction industry may soon benefit from 3D printed molds to make concrete facades, promising lower cost and production time. Researchers at Oak Ridge National Laboratory are evaluating the performance of 3D printed molds used to precast concrete facades in a 42-story buildin...

Oak Ridge National Laboratory scientists have improved a mixture of materials used to 3D print permanent magnets with increased density, which could yield longer lasting, better performing magnets for electric motors, sensors and vehicle applications. Building on previous research, ...

As leader of the RF, Communications, and Cyber-Physical Security Group at Oak Ridge National Laboratory, Kerekes heads an accelerated lab-directed research program to build virtual models of critical infrastructure systems like the power grid that can be used to develop ways to detect and repel cyber-intrusion and to make the network resilient when disruption occurs.

Oak Ridge National Laboratory has developed a salt purification lab to study the viability of using liquid salt that contains lithium fluoride and beryllium fluoride, known as FLiBe, to cool molten salt reactors, or MSRs. Multiple American companies developing advanced reactor technol...

Thanks in large part to developing and operating a facility for testing molten salt reactor (MSR) technologies, nuclear experts at the Energy Department’s Oak Ridge National Laboratory (ORNL) are now tackling the next generation of another type of clean energy—concentrating ...

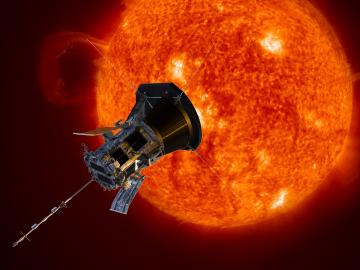

A shield assembly that protects an instrument measuring ion and electron fluxes for a NASA mission to touch the Sun was tested in extreme experimental environments at Oak Ridge National Laboratory—and passed with flying colors. Components aboard Parker Solar Probe, which will endure th...

Last November a team of students and educators from Robertsville Middle School in Oak Ridge and scientists from Oak Ridge National Laboratory submitted a proposal to NASA for their Cube Satellite Launch Initiative in hopes of sending a student-designed nanosatellite named RamSat into...

With the licensing to Enchi Corporation of a microbe custom-designed to produce ethanol efficiently, Oak Ridge National Laboratory (ORNL) and the BioEnergy Science Center (BESC) mark the culmination of 10 years’ research into ways to improve biofuels production. Enchi ha...

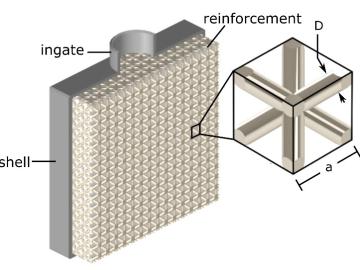

A new manufacturing method created by Oak Ridge National Laboratory and Rice University combines 3D printing with traditional casting to produce damage-tolerant components composed of multiple materials. Composite components made by pouring an aluminum alloy over a printed steel lattice showed an order of magnitude greater damage tolerance than aluminum alone.