Filter News

Area of Research

- (-) Materials (226)

- Advanced Manufacturing (14)

- Biological Systems (15)

- Biology and Environment (42)

- Biology and Soft Matter (1)

- Building Technologies (3)

- Chemistry and Physics at Interfaces (4)

- Clean Energy (187)

- Climate and Environmental Systems (2)

- Computational Biology (4)

- Computational Engineering (2)

- Computer Science (6)

- Electricity and Smart Grid (1)

- Energy Frontier Research Centers (7)

- Energy Sciences (3)

- Fossil Energy (2)

- Fuel Cycle Science and Technology (1)

- Functional Materials for Energy (8)

- Fusion and Fission (19)

- Fusion Energy (2)

- Geographic Information Science and Technology (2)

- Isotope Development and Production (1)

- Isotopes (10)

- Materials Characterization (2)

- Materials for Computing (13)

- Materials Synthesis from Atoms to Systems (5)

- Materials Under Extremes (5)

- National Security (25)

- Neutron Science (80)

- Nuclear Science and Technology (27)

- Nuclear Systems Modeling, Simulation and Validation (1)

- Nuclear Systems Technology (1)

- Quantum Condensed Matter (1)

- Quantum information Science (2)

- Reactor Technology (1)

- Sensors and Controls (1)

- Supercomputing (115)

- Transportation Systems (5)

News Type

News Topics

- 3-D Printing/Advanced Manufacturing (13)

- Advanced Reactors (2)

- Artificial Intelligence (5)

- Bioenergy (8)

- Biology (4)

- Biomedical (3)

- Buildings (3)

- Chemical Sciences (21)

- Climate Change (5)

- Composites (3)

- Computer Science (8)

- Coronavirus (2)

- Critical Materials (8)

- Cybersecurity (3)

- Decarbonization (5)

- Energy Storage (20)

- Environment (8)

- Exascale Computing (1)

- Frontier (3)

- Fusion (2)

- Grid (3)

- High-Performance Computing (3)

- Irradiation (1)

- Isotopes (5)

- ITER (1)

- Machine Learning (3)

- Materials (43)

- Materials Science (37)

- Microscopy (14)

- Molten Salt (2)

- Nanotechnology (21)

- National Security (3)

- Net Zero (1)

- Neutron Science (19)

- Nuclear Energy (3)

- Partnerships (9)

- Physics (14)

- Polymers (6)

- Quantum Computing (1)

- Quantum Science (10)

- Renewable Energy (1)

- Security (1)

- Simulation (1)

- Summit (1)

- Sustainable Energy (8)

- Transformational Challenge Reactor (1)

- Transportation (5)

Media Contacts

The Department of Energy’s Oak Ridge National Laboratory is now producing actinium-227 (Ac-227) to meet projected demand for a highly effective cancer drug through a 10-year contract between the U.S. DOE Isotope Program and Bayer.

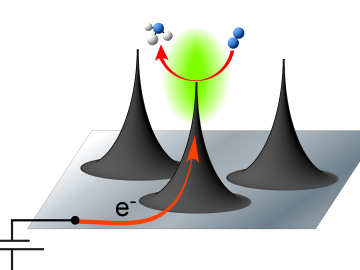

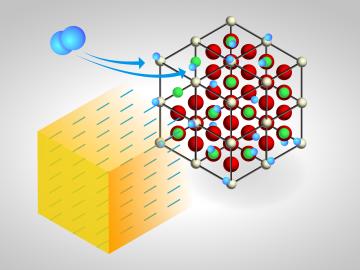

A scientific team led by the Department of Energy’s Oak Ridge National Laboratory has found a new way to take the local temperature of a material from an area about a billionth of a meter wide, or approximately 100,000 times thinner than a human hair. This discove...

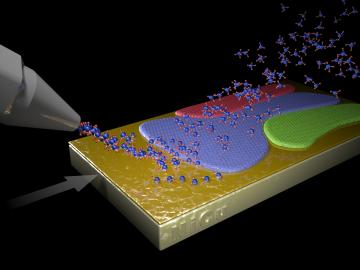

A new method to produce large, monolayer single-crystal-like graphene films more than a foot long relies on harnessing a “survival of the fittest” competition among crystals. The novel technique, developed by a team led by Oak Ridge National Laboratory, may open new opportunities for growing the high-quality two-dimensional materials necessary for long-awaited practical applications.

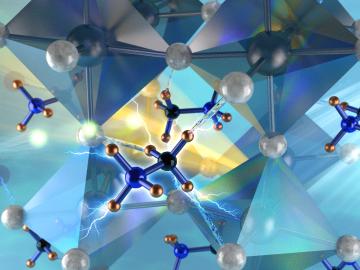

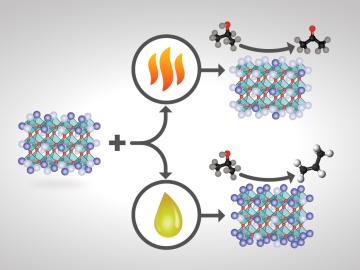

For some crystalline catalysts, what you see on the surface is not always what you get in the bulk, according to two studies led by the Department of Energy’s Oak Ridge National Laboratory. The investigators discovered that treating a complex