Filter News

Area of Research

- Advanced Manufacturing (14)

- Biological Systems (15)

- Biology and Environment (42)

- Biology and Soft Matter (1)

- Building Technologies (3)

- Chemistry and Physics at Interfaces (4)

- Clean Energy (187)

- Climate and Environmental Systems (2)

- Computational Biology (4)

- Computational Engineering (2)

- Computer Science (6)

- Electricity and Smart Grid (1)

- Energy Frontier Research Centers (7)

- Energy Sciences (3)

- Fossil Energy (2)

- Fuel Cycle Science and Technology (1)

- Functional Materials for Energy (8)

- Fusion and Fission (19)

- Fusion Energy (2)

- Geographic Information Science and Technology (2)

- Isotope Development and Production (1)

- Isotopes (10)

- Materials (226)

- Materials Characterization (2)

- Materials for Computing (13)

- Materials Synthesis from Atoms to Systems (5)

- Materials Under Extremes (5)

- National Security (25)

- Neutron Science (80)

- Nuclear Science and Technology (27)

- Nuclear Systems Modeling, Simulation and Validation (1)

- Nuclear Systems Technology (1)

- Quantum Condensed Matter (1)

- Quantum information Science (2)

- Reactor Technology (1)

- Sensors and Controls (1)

- Supercomputing (115)

- Transportation Systems (5)

News Type

Date

News Topics

- 3-D Printing/Advanced Manufacturing (50)

- Advanced Reactors (12)

- Artificial Intelligence (32)

- Big Data (11)

- Bioenergy (24)

- Biology (22)

- Biomedical (18)

- Biotechnology (7)

- Buildings (15)

- Chemical Sciences (33)

- Clean Water (2)

- Climate Change (25)

- Composites (10)

- Computer Science (62)

- Coronavirus (17)

- Critical Materials (11)

- Cybersecurity (18)

- Decarbonization (22)

- Education (3)

- Element Discovery (1)

- Energy Storage (45)

- Environment (44)

- Exascale Computing (12)

- Fossil Energy (1)

- Frontier (17)

- Fusion (14)

- Grid (18)

- High-Performance Computing (33)

- Irradiation (1)

- Isotopes (21)

- ITER (2)

- Machine Learning (14)

- Materials (67)

- Materials Science (53)

- Mercury (2)

- Microelectronics (1)

- Microscopy (18)

- Molten Salt (2)

- Nanotechnology (28)

- National Security (20)

- Net Zero (4)

- Neutron Science (56)

- Nuclear Energy (33)

- Partnerships (28)

- Physics (24)

- Polymers (13)

- Quantum Computing (10)

- Quantum Science (28)

- Renewable Energy (1)

- Security (11)

- Simulation (11)

- Software (1)

- Space Exploration (3)

- Statistics (1)

- Summit (22)

- Sustainable Energy (37)

- Transformational Challenge Reactor (4)

- Transportation (32)

Media Contacts

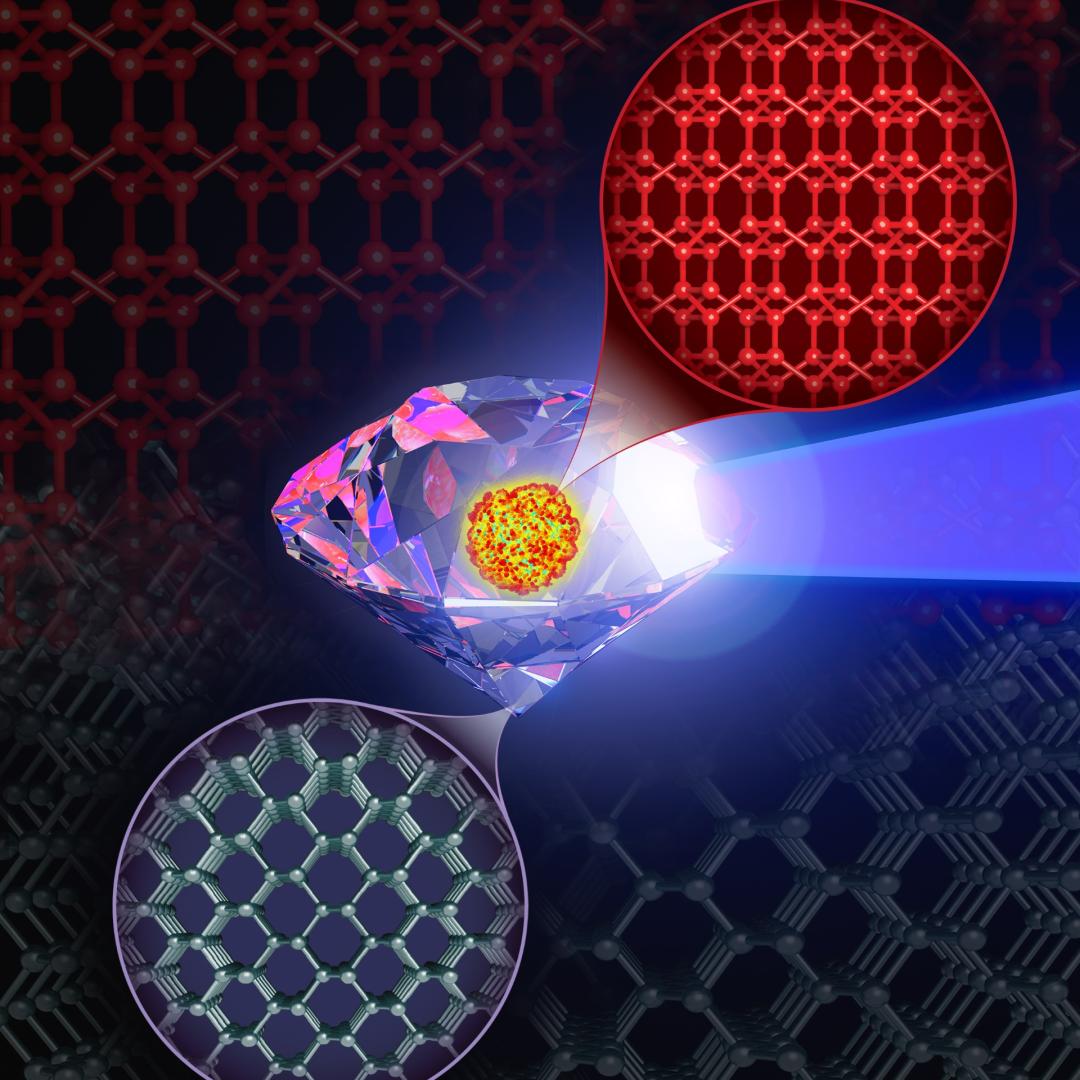

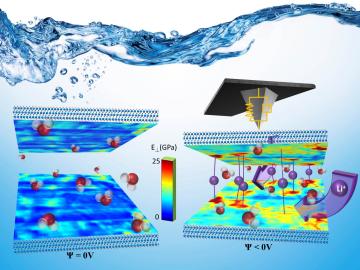

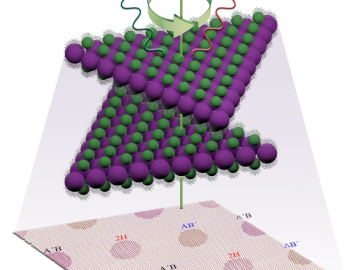

Researchers at the Department of Energy's Oak Ridge National Laboratory have combined advanced in-situ microscopy and theoretical calculations to uncover important clues to the properties of a promising next-generation energy storage material for

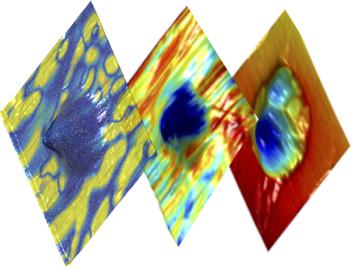

Measurement and data analysis techniques developed at the Department of Energy’s Oak Ridge National Laboratory could provide new insight into performance-robbing flaws in crystalline structures, ultimately improving the performance of solar cells.

Experts at the U.S. Department of Energy’s Oak Ridge National Laboratory will help nine small companies move their innovative manufacturing, buildings, fuel cell, geothermal and vehicle technologies closer to the marketplace. The businesses are among 33 selected t...

Three U.S. Department of Energy-funded research centers – the BioEnergy Science Center (Oak Ridge National Laboratory), the Great Lakes Bioenergy Research Center (University of Wisconsin–Madison and Michigan State University), and the Joint BioEnergy Institute (Lawrence Berkeley National Laboratory) – are making progress on a shared mission to develop technologies that will bring advanced biofuels to the marketplace, reporting today the disclosure of their 500th invention.

Adrian Sabau and Robert Wagner of the Department of Energy's Oak Ridge National Laboratory have been appointed fellows of the American Society of Mechanical Engineers (ASME), an honor conferred to members who have demonstrated significant, long-term engineering achievements.