Filter News

Area of Research

- (-) Advanced Manufacturing (19)

- (-) Materials for Computing (4)

- (-) National Security (8)

- Biology and Environment (42)

- Building Technologies (1)

- Computational Engineering (2)

- Computer Science (4)

- Electricity and Smart Grid (1)

- Energy Science (90)

- Functional Materials for Energy (1)

- Fusion and Fission (10)

- Fusion Energy (10)

- Isotopes (1)

- Materials (34)

- Mathematics (1)

- Neutron Science (9)

- Nuclear Science and Technology (8)

- Supercomputing (19)

News Type

News Topics

- (-) 3-D Printing/Advanced Manufacturing (24)

- (-) Environment (3)

- (-) Fusion (2)

- (-) Machine Learning (5)

- Advanced Reactors (2)

- Artificial Intelligence (7)

- Big Data (2)

- Bioenergy (2)

- Biology (2)

- Biomedical (3)

- Chemical Sciences (5)

- Composites (4)

- Computer Science (14)

- Coronavirus (3)

- Cybersecurity (12)

- Energy Storage (4)

- Exascale Computing (1)

- Frontier (1)

- Grid (3)

- High-Performance Computing (1)

- Isotopes (1)

- Materials (13)

- Materials Science (16)

- Microscopy (3)

- Nanotechnology (4)

- National Security (12)

- Neutron Science (5)

- Nuclear Energy (5)

- Partnerships (4)

- Physics (1)

- Polymers (5)

- Quantum Science (2)

- Security (7)

- Space Exploration (2)

- Summit (2)

- Transportation (5)

Media Contacts

Oak Ridge National Laboratory researchers combined additive manufacturing with conventional compression molding to produce high-performance thermoplastic composites reinforced with short carbon fibers.

A team of Oak Ridge National Laboratory researchers demonstrated that an additively manufactured hot stamping die – a tool used to create car body components – cooled faster than those produced by conventional manufacturing methods.

Oak Ridge National Laboratory researchers have demonstrated that a new class of superalloys made of cobalt and nickel remains crack-free and defect-resistant in extreme heat, making them conducive for use in metal-based 3D printing applications.

Collaborators at Oak Ridge National Laboratory and the University of Tennessee Health Science Center are developing a breath-sampling whistle that could make COVID-19 screening easy to do at home.

Scientists at Oak Ridge National Laboratory and the University of Tennessee designed and demonstrated a method to make carbon-based materials that can be used as electrodes compatible with a specific semiconductor circuitry.

Four research teams from the Department of Energy’s Oak Ridge National Laboratory and their technologies have received 2020 R&D 100 Awards.

The Society of Manufacturing Engineers, known as SME, has named William Peter, director of Oak Ridge National Laboratory’s Manufacturing Demonstration Facility in the Energy and Environmental Sciences Directorate, among its 2020 College of SME Fellows.

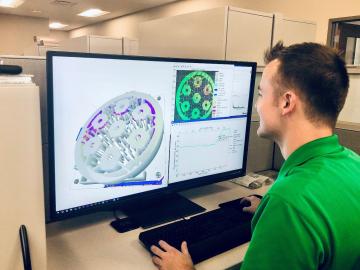

Oak Ridge National Laboratory researchers have developed artificial intelligence software for powder bed 3D printers that assesses the quality of parts in real time, without the need for expensive characterization equipment.

ORNL has licensed two additive manufacturing-related technologies that aim to streamline and ramp up production processes to Knoxville-based Magnum Venus Products, Inc., a global manufacturer of fluid movement and product solutions for industrial

OAK RIDGE, Tenn., Feb. 19, 2020 — The U.S. Department of Energy’s Oak Ridge National Laboratory and the Tennessee Valley Authority have signed a memorandum of understanding to evaluate a new generation of flexible, cost-effective advanced nuclear reactors.