Filter News

Area of Research

News Type

News Topics

- (-) 3-D Printing/Advanced Manufacturing (58)

- (-) Sustainable Energy (44)

- Advanced Reactors (12)

- Artificial Intelligence (39)

- Big Data (15)

- Bioenergy (40)

- Biology (44)

- Biomedical (28)

- Biotechnology (12)

- Buildings (25)

- Chemical Sciences (41)

- Clean Water (9)

- Climate Change (38)

- Composites (14)

- Computer Science (73)

- Coronavirus (23)

- Critical Materials (13)

- Cybersecurity (23)

- Decarbonization (36)

- Education (3)

- Element Discovery (1)

- Energy Storage (57)

- Environment (74)

- Exascale Computing (13)

- Fossil Energy (1)

- Frontier (18)

- Fusion (23)

- Grid (22)

- High-Performance Computing (39)

- Hydropower (2)

- Isotopes (30)

- ITER (3)

- Machine Learning (20)

- Materials (66)

- Materials Science (64)

- Mathematics (5)

- Mercury (6)

- Microelectronics (1)

- Microscopy (25)

- Molten Salt (3)

- Nanotechnology (32)

- National Security (34)

- Net Zero (5)

- Neutron Science (59)

- Nuclear Energy (42)

- Partnerships (30)

- Physics (40)

- Polymers (17)

- Quantum Computing (11)

- Quantum Science (29)

- Renewable Energy (1)

- Security (17)

- Simulation (14)

- Space Exploration (3)

- Statistics (1)

- Summit (23)

- Transformational Challenge Reactor (4)

- Transportation (37)

Media Contacts

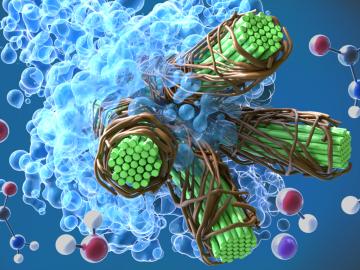

A team led by scientists at ORNL identified and demonstrated a method to process a plant-based material called nanocellulose that reduced energy needs by a whopping 21%, using simulations on the lab’s supercomputers and follow-on analysis.

ORNL is working with industry partners to develop a technique that combines 3D printing and conventional machining to produce large metal parts for clean energy applications. The project, known as Rapid Research on Universal Near Net Shape Fabrication Strategies for Expedited Runner Systems, or Rapid RUNNERS, recently received $15 million in funding from DOE.

Debjani Singh, a senior scientist at ORNL, leads the HydroSource project, which enhances hydropower research by making water data more accessible and useful. With a background in water resources, data science, and earth science, Singh applies innovative tools like AI to advance research. Her career, shaped by her early exposure to science in India, focuses on bridging research with practical applications.

Brittany Rodriguez never imagined she would pursue a science career at a Department of Energy national laboratory. However, after some encouraging words from her mother, input from key mentors at the University of Texas Rio Grande Valley, or UTRGV, and a lot of hard work, Rodriguez landed at DOE’s Manufacturing Demonstration Facility, or MDF, at Oak Ridge National Laboratory.

Alyssa Carrell started her science career studying the tallest inhabitants in the forest, but today is focused on some of its smallest — the microbial organisms that play an outsized role in plant health.

Canan Karakaya, a R&D Staff member in the Chemical Process Scale-Up group at ORNL, was inspired to become a chemical engineer after she experienced a magical transformation that turned ammonia gas into ammonium nitrate, turning a liquid into white flakes gently floating through the air.

The United States could triple its current bioeconomy by producing more than 1 billion tons per year of plant-based biomass for renewable fuels, while meeting projected demands for food, feed, fiber, conventional forest products and exports, according to the DOE’s latest Billion-Ton Report led by ORNL.

Four scientists affiliated with ORNL were named Battelle Distinguished Inventors during the lab’s annual Innovation Awards on Dec. 1 in recognition of being granted 14 or more United States patents.

The Department of Energy’s Office of Science has selected three ORNL research teams to receive funding through DOE’s new Biopreparedness Research Virtual Environment initiative.

A licensing agreement between the Department of Energy’s Oak Ridge National Laboratory and research partner ZEISS will enable industrial X-ray computed tomography, or CT, to perform rapid evaluations of 3D-printed components using ORNL’s machine