Filter News

Area of Research

News Topics

- (-) 3-D Printing/Advanced Manufacturing (43)

- (-) Partnerships (27)

- (-) Quantum Computing (9)

- Advanced Reactors (10)

- Artificial Intelligence (30)

- Big Data (7)

- Bioenergy (23)

- Biology (21)

- Biomedical (17)

- Biotechnology (7)

- Buildings (12)

- Chemical Sciences (28)

- Clean Water (2)

- Climate Change (22)

- Composites (9)

- Computer Science (57)

- Coronavirus (17)

- Critical Materials (11)

- Cybersecurity (17)

- Decarbonization (18)

- Education (3)

- Element Discovery (1)

- Energy Storage (41)

- Environment (35)

- Exascale Computing (9)

- Fossil Energy (1)

- Frontier (15)

- Fusion (14)

- Grid (15)

- High-Performance Computing (28)

- Isotopes (18)

- ITER (2)

- Machine Learning (13)

- Materials (57)

- Materials Science (49)

- Mercury (2)

- Microelectronics (1)

- Microscopy (16)

- Molten Salt (2)

- Nanotechnology (26)

- National Security (18)

- Net Zero (3)

- Neutron Science (49)

- Nuclear Energy (26)

- Physics (24)

- Polymers (12)

- Quantum Science (26)

- Renewable Energy (1)

- Security (11)

- Simulation (8)

- Space Exploration (3)

- Statistics (1)

- Summit (21)

- Sustainable Energy (30)

- Transformational Challenge Reactor (4)

- Transportation (25)

Media Contacts

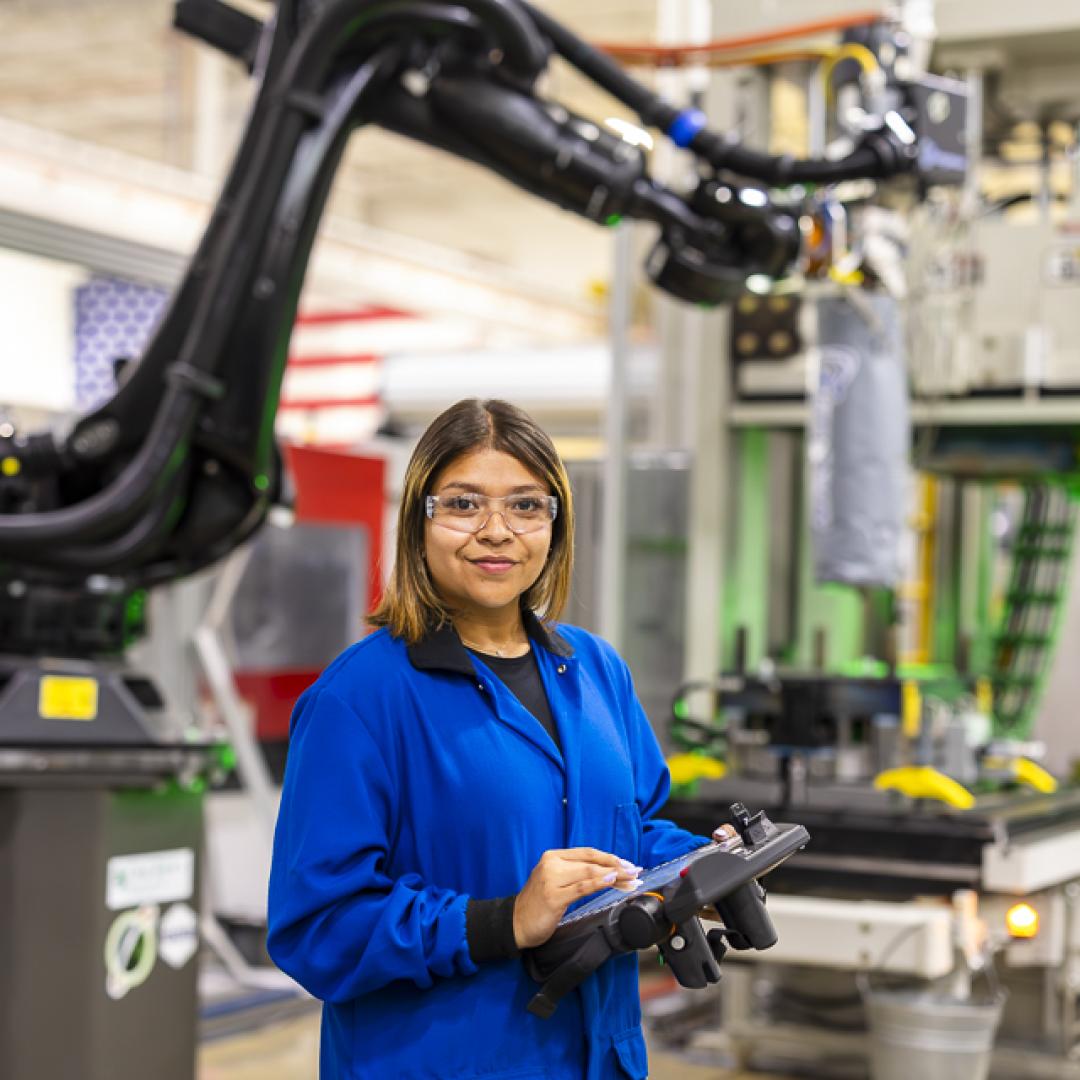

A new deep-learning framework developed at ORNL is speeding up the process of inspecting additively manufactured metal parts using X-ray computed tomography, or CT, while increasing the accuracy of the results. The reduced costs for time, labor, maintenance and energy are expected to accelerate expansion of additive manufacturing, or 3D printing.

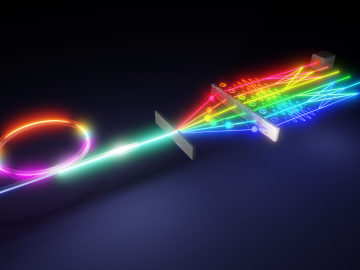

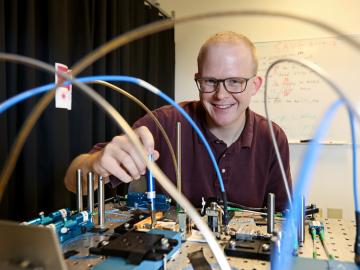

Using existing experimental and computational resources, a multi-institutional team has developed an effective method for measuring high-dimensional qudits encoded in quantum frequency combs, which are a type of photon source, on a single optical chip.

Five technologies invented by scientists at the Department of Energy’s Oak Ridge National Laboratory have been selected for targeted investment through ORNL’s Technology Innovation Program.

ORNL is sponsoring a cohort of 100Knoxville, a five-week mentorship and support program for Black founders of businesses.

ORNL researchers have developed an upcycling approach that adds value to discarded plastics for reuse in additive manufacturing, or 3D printing.

ORNL scientists will present new technologies available for licensing during the annual Technology Innovation Showcase. The event is 9 a.m. to 3 p.m. Thursday, June 16, at the Manufacturing Demonstration Facility at ORNL’s Hardin Valley campus.

Scientists’ increasing mastery of quantum mechanics is heralding a new age of innovation. Technologies that harness the power of nature’s most minute scale show enormous potential across the scientific spectrum

ORNL and the Tennessee Valley Authority, or TVA, are joining forces to advance decarbonization technologies from discovery through deployment through a new memorandum of understanding, or MOU.

ORNL, TVA and TNECD were recognized by the Federal Laboratory Consortium for their impactful partnership that resulted in a record $2.3 billion investment by Ultium Cells, a General Motors and LG Energy Solution joint venture, to build a battery cell manufacturing plant in Spring Hill, Tennessee.

A novel method to 3D print components for nuclear reactors, developed by the Department of Energy’s Oak Ridge National Laboratory, has been licensed by Ultra Safe Nuclear Corporation.