Filter News

Area of Research

- (-) Materials (51)

- (-) Neutron Science (13)

- (-) Sensors and Controls (1)

- Advanced Manufacturing (18)

- Biology and Environment (34)

- Building Technologies (1)

- Clean Energy (118)

- Climate and Environmental Systems (1)

- Computational Biology (1)

- Computational Engineering (3)

- Computer Science (7)

- Electricity and Smart Grid (1)

- Energy Sciences (1)

- Fusion and Fission (12)

- Fusion Energy (8)

- Isotopes (2)

- Materials for Computing (6)

- Mathematics (1)

- National Security (12)

- Nuclear Science and Technology (4)

- Quantum information Science (1)

- Supercomputing (41)

News Type

News Topics

- (-) 3-D Printing/Advanced Manufacturing (21)

- (-) Big Data (1)

- (-) Climate Change (5)

- (-) Energy Storage (29)

- (-) Fusion (5)

- (-) Grid (3)

- (-) Machine Learning (2)

- (-) Summit (4)

- Advanced Reactors (2)

- Artificial Intelligence (5)

- Bioenergy (11)

- Biology (8)

- Biomedical (11)

- Biotechnology (1)

- Buildings (3)

- Chemical Sciences (25)

- Clean Water (1)

- Composites (7)

- Computer Science (12)

- Coronavirus (8)

- Critical Materials (13)

- Cybersecurity (4)

- Decarbonization (6)

- Environment (11)

- Exascale Computing (1)

- Frontier (3)

- High-Performance Computing (3)

- Isotopes (7)

- ITER (1)

- Materials (54)

- Materials Science (59)

- Microscopy (18)

- Molten Salt (3)

- Nanotechnology (31)

- National Security (3)

- Net Zero (1)

- Neutron Science (65)

- Nuclear Energy (7)

- Partnerships (8)

- Physics (18)

- Polymers (12)

- Quantum Computing (2)

- Quantum Science (13)

- Renewable Energy (1)

- Security (3)

- Space Exploration (3)

- Sustainable Energy (11)

- Transformational Challenge Reactor (1)

- Transportation (13)

Media Contacts

Researchers at the Department of Energy’s Oak Ridge National Laboratory have received five 2019 R&D 100 Awards, increasing the lab’s total to 221 since the award’s inception in 1963.

ORNL and The University of Toledo have entered into a memorandum of understanding for collaborative research.

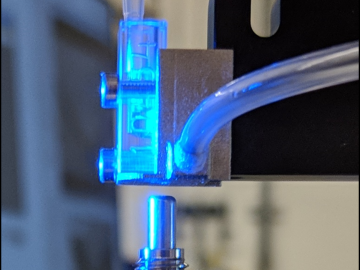

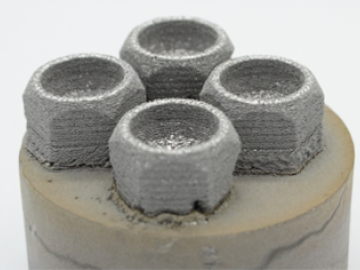

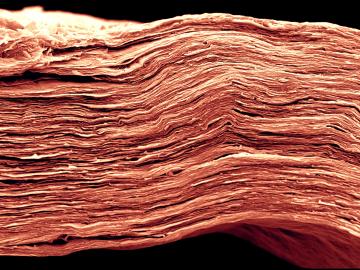

Using additive manufacturing, scientists experimenting with tungsten at Oak Ridge National Laboratory hope to unlock new potential of the high-performance heat-transferring material used to protect components from the plasma inside a fusion reactor. Fusion requires hydrogen isotopes to reach millions of degrees.

A team of researchers at Oak Ridge National Laboratory have demonstrated that designed synthetic polymers can serve as a high-performance binding material for next-generation lithium-ion batteries.

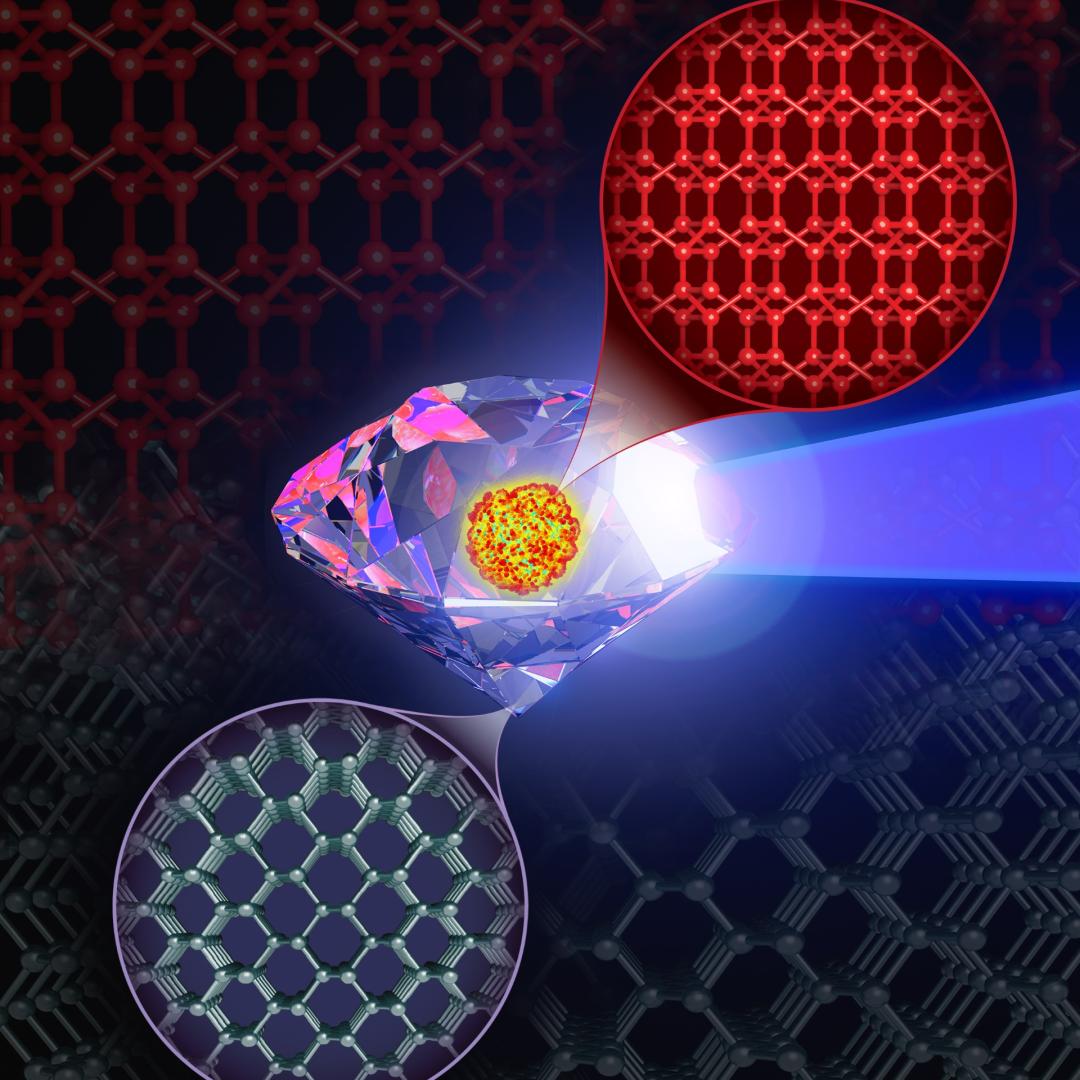

Scientists have tested a novel heat-shielding graphite foam, originally created at Oak Ridge National Laboratory, at Germany’s Wendelstein 7-X stellarator with promising results for use in plasma-facing components of fusion reactors.

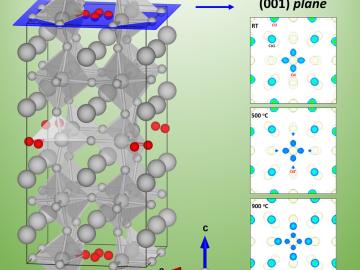

A University of South Carolina research team is investigating the oxygen reduction performance of energy conversion materials called perovskites by using neutron diffraction at Oak Ridge National Laboratory’s Spallation Neutron Source.

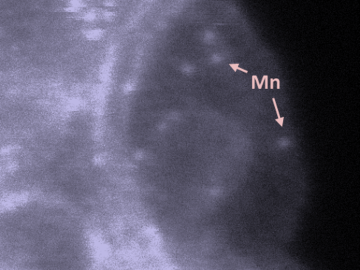

Oak Ridge National Laboratory scientists studying fuel cells as a potential alternative to internal combustion engines used sophisticated electron microscopy to investigate the benefits of replacing high-cost platinum with a lower cost, carbon-nitrogen-manganese-based catalyst.

Scientists at the Department of Energy’s Oak Ridge National Laboratory have created a recipe for a renewable 3D printing feedstock that could spur a profitable new use for an intractable biorefinery byproduct: lignin.

Oak Ridge National Laboratory scientists have improved a mixture of materials used to 3D print permanent magnets with increased density, which could yield longer lasting, better performing magnets for electric motors, sensors and vehicle applications. Building on previous research, ...