Filter News

Area of Research

- Advanced Manufacturing (18)

- Biology and Environment (21)

- Building Technologies (1)

- Clean Energy (90)

- Computational Biology (1)

- Computational Engineering (1)

- Computer Science (4)

- Electricity and Smart Grid (1)

- Fusion and Fission (6)

- Fusion Energy (3)

- Isotope Development and Production (1)

- Isotopes (4)

- Materials (78)

- Materials Characterization (1)

- Materials for Computing (12)

- Materials Under Extremes (1)

- National Security (16)

- Neutron Science (27)

- Nuclear Science and Technology (8)

- Quantum information Science (2)

- Sensors and Controls (1)

- Supercomputing (41)

- Transportation Systems (1)

News Type

News Topics

- (-) 3-D Printing/Advanced Manufacturing (74)

- (-) Biomedical (28)

- (-) Cybersecurity (20)

- (-) Exascale Computing (10)

- (-) Frontier (15)

- (-) Grid (35)

- (-) Materials Science (82)

- (-) Partnerships (28)

- (-) Space Exploration (13)

- Advanced Reactors (23)

- Artificial Intelligence (42)

- Big Data (23)

- Bioenergy (38)

- Biology (38)

- Biotechnology (10)

- Buildings (31)

- Chemical Sciences (37)

- Clean Water (14)

- Climate Change (43)

- Composites (18)

- Computer Science (96)

- Coronavirus (28)

- Critical Materials (23)

- Decarbonization (26)

- Education (3)

- Element Discovery (1)

- Energy Storage (72)

- Environment (77)

- Fossil Energy (1)

- Fusion (23)

- High-Performance Computing (37)

- Hydropower (6)

- Irradiation (2)

- Isotopes (23)

- ITER (5)

- Machine Learning (23)

- Materials (92)

- Mathematics (1)

- Mercury (5)

- Microelectronics (1)

- Microscopy (27)

- Molten Salt (7)

- Nanotechnology (38)

- National Security (21)

- Net Zero (4)

- Neutron Science (76)

- Nuclear Energy (45)

- Physics (28)

- Polymers (21)

- Quantum Computing (13)

- Quantum Science (36)

- Renewable Energy (1)

- Security (12)

- Simulation (15)

- Statistics (2)

- Summit (26)

- Sustainable Energy (74)

- Transformational Challenge Reactor (4)

- Transportation (60)

Media Contacts

Six firms received Small Business Awards from the Department of Energy’s Oak Ridge National Laboratory. The companies, selected from small business service providers to the lab, were recognized by ORNL's Small Business Programs Office for their specific capabilities and contributions.

Oak Ridge National Laboratory scientists ingeniously created a sustainable, soft material by combining rubber with woody reinforcements and incorporating “smart” linkages between the components that unlock on demand.

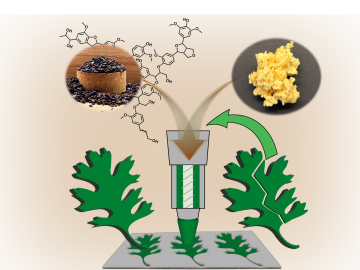

ORNL scientists develop a sample holder that tumbles powdered photochemical materials within a neutron beamline — exposing more of the material to light for increased photo-activation and better photochemistry data capture.

ORNL researchers used electron-beam additive manufacturing to 3D-print the first complex, defect-free tungsten parts with complex geometries.

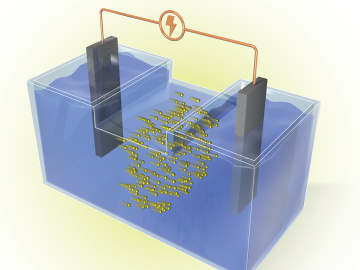

Researchers at ORNL are developing battery technologies to fight climate change in two ways, by expanding the use of renewable energy and capturing airborne carbon dioxide.

A collection of seven technologies for lithium recovery developed by scientists from ORNL has been licensed to Element3, a Texas-based company focused on extracting lithium from wastewater produced by oil and gas production.

Two different teams that included Oak Ridge National Laboratory employees were honored Feb. 20 with Secretary’s Honor Achievement Awards from the Department of Energy. This is DOE's highest form of employee recognition.

Four ORNL teams and one researcher were recognized for excellence in technology transfer and technology transfer innovation.

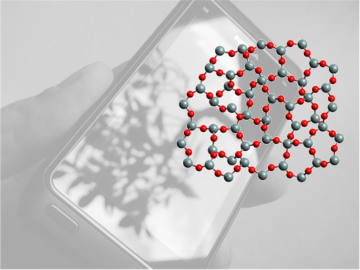

Corning uses neutron scattering to study the stability of different types of glass. Recently, researchers for the company have found that understanding the stability of the rings of atoms in glass materials can help predict the performance of glass products.

Ateios Systems licensed an ORNL technology for solvent-free battery component production using electron curing. Through Innovation Crossroads, Ateios continues to work with ORNL to enable readiness for production-quality battery components.