Filter News

Area of Research

News Type

News Topics

- (-) 3-D Printing/Advanced Manufacturing (43)

- (-) Mercury (7)

- (-) Nanotechnology (18)

- Advanced Reactors (15)

- Artificial Intelligence (17)

- Big Data (21)

- Bioenergy (32)

- Biology (38)

- Biomedical (19)

- Biotechnology (7)

- Buildings (27)

- Chemical Sciences (17)

- Clean Water (19)

- Climate Change (36)

- Composites (11)

- Computer Science (52)

- Coronavirus (17)

- Critical Materials (13)

- Cybersecurity (9)

- Decarbonization (23)

- Energy Storage (45)

- Environment (80)

- Exascale Computing (4)

- Frontier (4)

- Fusion (16)

- Grid (27)

- High-Performance Computing (20)

- Hydropower (8)

- Irradiation (2)

- Isotopes (14)

- ITER (4)

- Machine Learning (15)

- Materials (42)

- Materials Science (45)

- Mathematics (5)

- Microscopy (20)

- Molten Salt (5)

- National Security (18)

- Net Zero (3)

- Neutron Science (35)

- Nuclear Energy (32)

- Partnerships (1)

- Physics (20)

- Polymers (14)

- Quantum Computing (5)

- Quantum Science (12)

- Security (7)

- Simulation (10)

- Space Exploration (10)

- Statistics (1)

- Summit (8)

- Sustainable Energy (57)

- Transportation (47)

Media Contacts

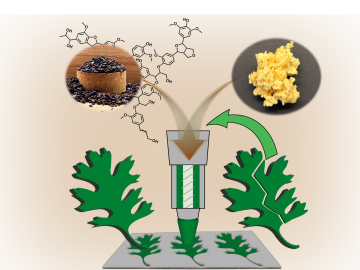

Oak Ridge National Laboratory scientists ingeniously created a sustainable, soft material by combining rubber with woody reinforcements and incorporating “smart” linkages between the components that unlock on demand.

Canan Karakaya, a R&D Staff member in the Chemical Process Scale-Up group at ORNL, was inspired to become a chemical engineer after she experienced a magical transformation that turned ammonia gas into ammonium nitrate, turning a liquid into white flakes gently floating through the air.

An Oak Ridge National Laboratory-developed advanced manufacturing technology, AMCM, was recently licensed by Orbital Composites and enables the rapid production of composite-based components, which could accelerate the decarbonization of vehicles

Oak Ridge National Laboratory researchers have conducted a comprehensive life cycle, cost and carbon emissions analysis on 3D-printed molds for precast concrete and determined the method is economically beneficial compared to conventional wood molds.

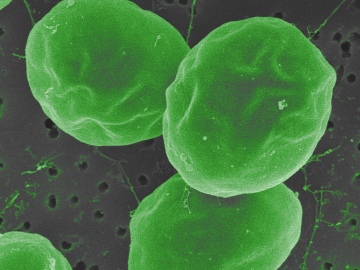

In the search for ways to fight methylmercury in global waterways, scientists at Oak Ridge National Laboratory discovered that some forms of phytoplankton are good at degrading the potent neurotoxin.

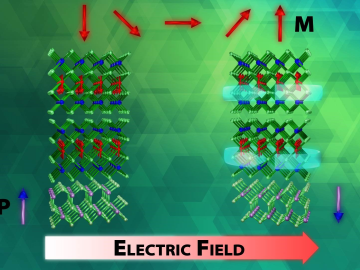

An advance in a topological insulator material — whose interior behaves like an electrical insulator but whose surface behaves like a conductor — could revolutionize the fields of next-generation electronics and quantum computing, according to scientists at ORNL.

When reading the novel Jurassic Park as a teenager, Jerry Parks found the passages about gene sequencing and supercomputers fascinating, but never imagined he might someday pursue such futuristic-sounding science.

Growing up in China, Yue Yuan stood beneath the world’s largest hydroelectric dam, built to harness the world’s third-longest river. Her father brought her to Three Gorges Dam every year as it was being constructed across the Yangtze River so she could witness its progress.

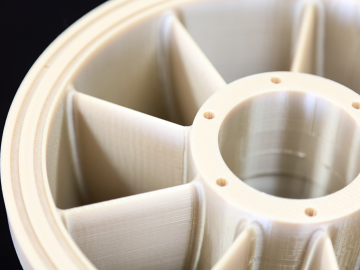

A new report published by ORNL assessed how advanced manufacturing and materials, such as 3D printing and novel component coatings, could offer solutions to modernize the existing fleet and design new approaches to hydropower.

ORNL researchers have identified a mechanism in a 3D-printed alloy – termed “load shuffling” — that could enable the design of better-performing lightweight materials for vehicles.