Filter News

Area of Research

News Type

News Topics

- (-) 3-D Printing/Advanced Manufacturing (43)

- (-) Irradiation (2)

- (-) Sustainable Energy (57)

- Advanced Reactors (15)

- Artificial Intelligence (17)

- Big Data (21)

- Bioenergy (32)

- Biology (38)

- Biomedical (19)

- Biotechnology (7)

- Buildings (27)

- Chemical Sciences (17)

- Clean Water (19)

- Climate Change (36)

- Composites (11)

- Computer Science (52)

- Coronavirus (17)

- Critical Materials (13)

- Cybersecurity (9)

- Decarbonization (23)

- Energy Storage (45)

- Environment (80)

- Exascale Computing (4)

- Frontier (4)

- Fusion (16)

- Grid (27)

- High-Performance Computing (20)

- Hydropower (8)

- Isotopes (14)

- ITER (4)

- Machine Learning (15)

- Materials (42)

- Materials Science (45)

- Mathematics (5)

- Mercury (7)

- Microscopy (20)

- Molten Salt (5)

- Nanotechnology (18)

- National Security (18)

- Net Zero (3)

- Neutron Science (35)

- Nuclear Energy (32)

- Partnerships (1)

- Physics (20)

- Polymers (14)

- Quantum Computing (5)

- Quantum Science (12)

- Security (7)

- Simulation (10)

- Space Exploration (10)

- Statistics (1)

- Summit (8)

- Transportation (47)

Media Contacts

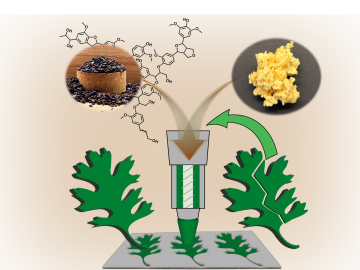

Oak Ridge National Laboratory scientists ingeniously created a sustainable, soft material by combining rubber with woody reinforcements and incorporating “smart” linkages between the components that unlock on demand.

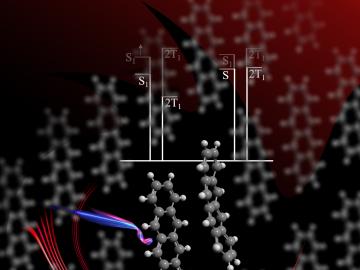

ORNL scientists develop a sample holder that tumbles powdered photochemical materials within a neutron beamline — exposing more of the material to light for increased photo-activation and better photochemistry data capture.

ORNL researchers used electron-beam additive manufacturing to 3D-print the first complex, defect-free tungsten parts with complex geometries.

Alyssa Carrell started her science career studying the tallest inhabitants in the forest, but today is focused on some of its smallest — the microbial organisms that play an outsized role in plant health.

Canan Karakaya, a R&D Staff member in the Chemical Process Scale-Up group at ORNL, was inspired to become a chemical engineer after she experienced a magical transformation that turned ammonia gas into ammonium nitrate, turning a liquid into white flakes gently floating through the air.

An Oak Ridge National Laboratory-developed advanced manufacturing technology, AMCM, was recently licensed by Orbital Composites and enables the rapid production of composite-based components, which could accelerate the decarbonization of vehicles

Oak Ridge National Laboratory researchers have conducted a comprehensive life cycle, cost and carbon emissions analysis on 3D-printed molds for precast concrete and determined the method is economically beneficial compared to conventional wood molds.

Mirko Musa spent his childhood zigzagging his bike along the Po River. The Po, Italy’s longest river, cuts through a lush valley of grain and vegetable fields, which look like a green and gold ocean spreading out from the river’s banks.

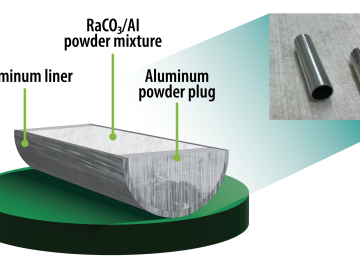

Oak Ridge National Laboratory researchers have developed a method to simplify one step of radioisotope production — and it’s faster and safer.

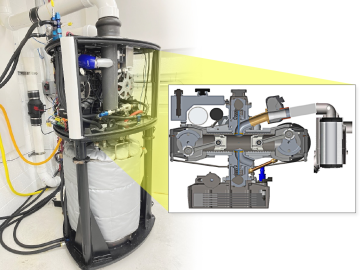

ORNL researchers, in collaboration with Enginuity Power Systems, demonstrated that a micro combined heat and power prototype, or mCHP, with a piston engine can achieve an overall energy efficiency greater than 93%.