Filter News

Area of Research

News Type

News Topics

- (-) Composites (11)

- (-) Exascale Computing (4)

- (-) Frontier (4)

- 3-D Printing/Advanced Manufacturing (43)

- Advanced Reactors (15)

- Artificial Intelligence (17)

- Big Data (21)

- Bioenergy (32)

- Biology (38)

- Biomedical (19)

- Biotechnology (7)

- Buildings (27)

- Chemical Sciences (17)

- Clean Water (19)

- Climate Change (36)

- Computer Science (52)

- Coronavirus (17)

- Critical Materials (13)

- Cybersecurity (9)

- Decarbonization (23)

- Energy Storage (45)

- Environment (80)

- Fusion (16)

- Grid (27)

- High-Performance Computing (20)

- Hydropower (8)

- Irradiation (2)

- Isotopes (14)

- ITER (4)

- Machine Learning (15)

- Materials (42)

- Materials Science (45)

- Mathematics (5)

- Mercury (7)

- Microscopy (20)

- Molten Salt (5)

- Nanotechnology (18)

- National Security (18)

- Net Zero (3)

- Neutron Science (35)

- Nuclear Energy (32)

- Partnerships (1)

- Physics (20)

- Polymers (14)

- Quantum Computing (5)

- Quantum Science (12)

- Security (7)

- Simulation (10)

- Space Exploration (10)

- Statistics (1)

- Summit (8)

- Sustainable Energy (57)

- Transportation (47)

Media Contacts

John Lagergren, a staff scientist in Oak Ridge National Laboratory’s Plant Systems Biology group, is using his expertise in applied math and machine learning to develop neural networks to quickly analyze the vast amounts of data on plant traits amassed at ORNL’s Advanced Plant Phenotyping Laboratory.

Electric vehicles can drive longer distances if their lithium-ion batteries deliver more energy in a lighter package. A prime weight-loss candidate is the current collector, a component that often adds 10% to the weight of a battery cell without contributing energy.

At the National Center for Computational Sciences, Ashley Barker enjoys one of the least complicated–sounding job titles at ORNL: section head of operations. But within that seemingly ordinary designation lurks a multitude of demanding roles as she oversees the complete user experience for NCCS computer systems.

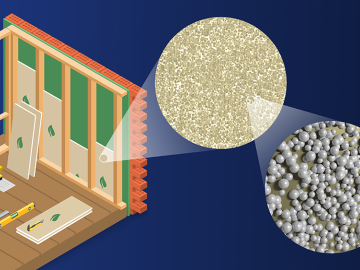

Scientists at ORNL developed a competitive, eco-friendly alternative made without harmful blowing agents.

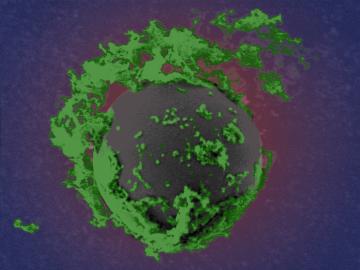

The presence of minerals called ash in plants makes little difference to the fitness of new naturally derived compound materials designed for additive manufacturing, an Oak Ridge National Laboratory-led team found.

Oak Ridge National Laboratory scientists designed a recyclable polymer for carbon-fiber composites to enable circular manufacturing of parts that boost energy efficiency in automotive, wind power and aerospace applications.

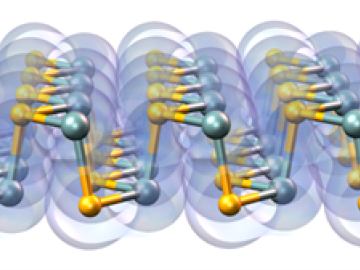

A multi-lab research team led by ORNL's Paul Kent is developing a computer application called QMCPACK to enable precise and reliable predictions of the fundamental properties of materials critical in energy research.

Chemical and environmental engineer Samarthya Bhagia is focused on achieving carbon neutrality and a circular economy by designing new plant-based materials for a range of applications from energy storage devices and sensors to environmentally friendly bioplastics.

A research team at Oak Ridge National Laboratory have 3D printed a thermal protection shield, or TPS, for a capsule that will launch with the Cygnus cargo spacecraft as part of the supply mission to the International Space Station.