Filter News

Area of Research

- (-) Clean Energy (42)

- (-) Fusion and Fission (9)

- (-) Nuclear Science and Technology (14)

- Advanced Manufacturing (5)

- Biology and Environment (36)

- Climate and Environmental Systems (1)

- Computational Biology (1)

- Computational Engineering (1)

- Computer Science (5)

- Electricity and Smart Grid (1)

- Fusion Energy (7)

- Isotopes (4)

- Materials (34)

- Materials for Computing (7)

- National Security (9)

- Neutron Science (28)

- Nuclear Systems Modeling, Simulation and Validation (1)

- Quantum information Science (1)

- Sensors and Controls (1)

- Supercomputing (8)

- Transportation Systems (1)

News Type

News Topics

- (-) Biology (3)

- (-) Biomedical (4)

- (-) Fusion (7)

- (-) Grid (21)

- (-) Machine Learning (2)

- (-) Materials Science (10)

- (-) Neutron Science (3)

- (-) Nuclear Energy (17)

- (-) Physics (2)

- (-) Security (2)

- (-) Space Exploration (3)

- 3-D Printing/Advanced Manufacturing (33)

- Advanced Reactors (6)

- Artificial Intelligence (1)

- Big Data (2)

- Bioenergy (4)

- Biotechnology (1)

- Buildings (19)

- Chemical Sciences (2)

- Clean Water (5)

- Climate Change (8)

- Composites (9)

- Computer Science (10)

- Coronavirus (6)

- Critical Materials (6)

- Cybersecurity (2)

- Decarbonization (12)

- Energy Storage (33)

- Environment (21)

- High-Performance Computing (1)

- Hydropower (2)

- Isotopes (2)

- ITER (3)

- Materials (14)

- Mathematics (2)

- Mercury (2)

- Microscopy (3)

- Molten Salt (3)

- Nanotechnology (1)

- National Security (1)

- Net Zero (2)

- Polymers (5)

- Simulation (1)

- Statistics (1)

- Summit (1)

- Sustainable Energy (33)

- Transportation (37)

Media Contacts

A research team led by Oak Ridge National Laboratory bioengineered a microbe to efficiently turn waste into itaconic acid, an industrial chemical used in plastics and paints.

An Oak Ridge National Laboratory research team discovered that aspen saplings emerging after wildfire have less diverse microbiomes and more pathogens in their leaves, providing new insights about how fire affects ecosystem recovery.

A method developed at Oak Ridge National Laboratory to print high-fidelity, passive sensors for energy applications can reduce the cost of monitoring critical power grid assets.

For a researcher who started out in mechanical engineering with a focus on engine combustion, Martin Wissink has learned a lot about neutrons on the job

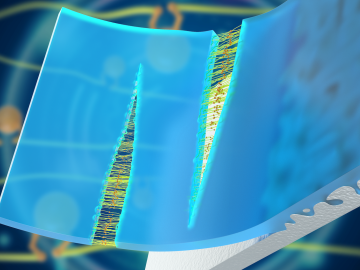

Oak Ridge National Laboratory researchers have demonstrated that a new class of superalloys made of cobalt and nickel remains crack-free and defect-resistant in extreme heat, making them conducive for use in metal-based 3D printing applications.

From the helm of a one-of-a-kind organization that brings nuclear fusion and fission expertise together to pave the way to expanding carbon-free energy, Kathy McCarthy can trace the first step of her engineering career back to

A new Department of Energy report produced by Oak Ridge National Laboratory details national and international trends in hydropower, including the role waterpower plays in enhancing the flexibility and resilience of the power grid.

Growing up in the heart of the American automobile industry near Detroit, Oak Ridge National Laboratory materials scientist Mike Kirka was no stranger to manufacturing.

As program manager for the Department of Energy’s Oak Ridge National Laboratory’s Package Testing Program, Oscar Martinez enjoys finding and fixing technical issues.