Filter News

Area of Research

- Advanced Manufacturing (3)

- Biology and Environment (20)

- Building Technologies (3)

- Clean Energy (46)

- Climate and Environmental Systems (1)

- Computational Engineering (1)

- Computer Science (1)

- Fusion and Fission (2)

- Isotopes (10)

- Materials (32)

- Materials for Computing (5)

- Mathematics (1)

- National Security (6)

- Neutron Science (28)

- Nuclear Science and Technology (5)

- Quantum information Science (1)

- Supercomputing (8)

News Type

News Topics

- (-) Buildings (29)

- (-) Chemical Sciences (20)

- (-) Climate Change (38)

- (-) Composites (12)

- (-) Cybersecurity (9)

- (-) Isotopes (16)

- (-) Microscopy (20)

- (-) Neutron Science (35)

- (-) Polymers (14)

- (-) Space Exploration (10)

- 3-D Printing/Advanced Manufacturing (44)

- Advanced Reactors (15)

- Artificial Intelligence (18)

- Big Data (24)

- Bioenergy (33)

- Biology (40)

- Biomedical (21)

- Biotechnology (7)

- Clean Water (20)

- Computer Science (53)

- Coronavirus (17)

- Critical Materials (14)

- Decarbonization (25)

- Energy Storage (45)

- Environment (81)

- Exascale Computing (4)

- Fossil Energy (1)

- Frontier (4)

- Fusion (16)

- Grid (28)

- High-Performance Computing (20)

- Hydropower (8)

- Irradiation (2)

- ITER (4)

- Machine Learning (17)

- Materials (42)

- Materials Science (46)

- Mathematics (6)

- Mercury (7)

- Molten Salt (5)

- Nanotechnology (18)

- National Security (19)

- Net Zero (4)

- Nuclear Energy (34)

- Partnerships (1)

- Physics (20)

- Quantum Computing (5)

- Quantum Science (12)

- Security (7)

- Simulation (11)

- Statistics (1)

- Summit (8)

- Sustainable Energy (59)

- Transportation (47)

Media Contacts

A digital construction platform in development at Oak Ridge National Laboratory is boosting the retrofitting of building envelopes and giving builders the tools to automate the process from design to installation with the assistance of a cable-driven robotic crane.

Jeremiah Sewell leads a team at ORNL, working on xenon-129 production for lung imaging. Reflecting on his career, Sewell views each opportunity as a "door" he steps through, leveraging over 25 years of experience in nuclear power and centrifuge operations to advance the facility’s mission.

Researchers at ORNL have demonstrated that small molecular tweaks to surfaces can improve absorption technology for direct air capture of carbon dioxide. The team added a charged polymer layer to an amino acid solution, and then, through spectroscopy and simulation, found that the charged layer can hold amino acids at its surface.

Brittany Rodriguez never imagined she would pursue a science career at a Department of Energy national laboratory. However, after some encouraging words from her mother, input from key mentors at the University of Texas Rio Grande Valley, or UTRGV, and a lot of hard work, Rodriguez landed at DOE’s Manufacturing Demonstration Facility, or MDF, at Oak Ridge National Laboratory.

Oak Ridge National Laboratory scientists have developed a method leveraging artificial intelligence to accelerate the identification of environmentally friendly solvents for industrial carbon capture, biomass processing, rechargeable batteries and other applications.

An Oak Ridge National Laboratory team revealed how chemical species form in a highly reactive molten salt mixture of aluminum chloride and potassium chloride by unraveling vibrational signatures and observing ion exchanges.

Sara Martinez ensures the safety and longevity of aging structures at Oak Ridge National Laboratory, employing her engineering expertise to protect against natural disasters and extend the lifespan of critical facilities.

Researchers at Oak Ridge National Laboratory have developed free data sets to estimate how much energy any building in the contiguous U.S. will use in 2100. These data sets provide planners a way to anticipate future energy needs as the climate changes.

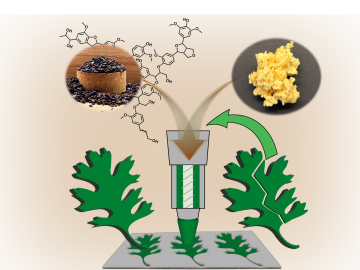

Oak Ridge National Laboratory scientists ingeniously created a sustainable, soft material by combining rubber with woody reinforcements and incorporating “smart” linkages between the components that unlock on demand.

Early career scientist Frankie White's was part of two major isotope projects at the same time he was preparing to be a father. As co-lead on a team that achieved the first synthesis and characterization of a radium compound using single crystal X-ray diffraction and part of a team that characterized the properties of promethium, White reflects on the life-changing timeline at work, and at home.