Filter News

Area of Research

- (-) Clean Energy (152)

- (-) Computational Engineering (2)

- Advanced Manufacturing (15)

- Biological Systems (2)

- Biology and Environment (32)

- Building Technologies (7)

- Chemical and Engineering Materials (1)

- Climate and Environmental Systems (4)

- Computational Biology (1)

- Computer Science (10)

- Electricity and Smart Grid (1)

- Energy Sciences (2)

- Fossil Energy (1)

- Fusion and Fission (4)

- Fusion Energy (8)

- Isotope Development and Production (1)

- Isotopes (5)

- Materials (75)

- Materials for Computing (10)

- Mathematics (1)

- National Security (8)

- Neutron Data Analysis and Visualization (2)

- Neutron Science (35)

- Nuclear Science and Technology (18)

- Nuclear Systems Modeling, Simulation and Validation (2)

- Quantum information Science (3)

- Renewable Energy (2)

- Sensors and Controls (2)

- Supercomputing (41)

- Transportation Systems (2)

News Type

News Topics

- 3-D Printing/Advanced Manufacturing (23)

- Artificial Intelligence (2)

- Big Data (2)

- Bioenergy (2)

- Biology (2)

- Biomedical (1)

- Biotechnology (1)

- Buildings (13)

- Chemical Sciences (1)

- Clean Water (4)

- Climate Change (6)

- Composites (9)

- Computer Science (10)

- Coronavirus (2)

- Critical Materials (4)

- Decarbonization (4)

- Energy Storage (21)

- Environment (15)

- Grid (15)

- High-Performance Computing (1)

- Hydropower (2)

- Machine Learning (3)

- Materials (12)

- Materials Science (9)

- Mathematics (1)

- Mercury (1)

- Microscopy (2)

- Nanotechnology (1)

- Net Zero (1)

- Nuclear Energy (1)

- Polymers (5)

- Simulation (1)

- Space Exploration (2)

- Statistics (1)

- Sustainable Energy (27)

- Transportation (26)

Media Contacts

Scientists at Oak Ridge National Laboratory are using the precision of an electron beam to instantly adhere cathode coatings for lithium-ion batteries—a leap in efficiency that saves energy, reduces production and capital costs, and eliminates the use of toxic solvents.

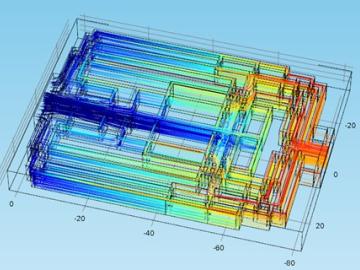

Oak Ridge National Laboratory has successfully developed and tested a novel sand casting technique to quickly design complex patterns to fabricate components for industry partner Emrgy Hydro, makers of hydropower devices designed to generate electricity from slow or shallow water flo...

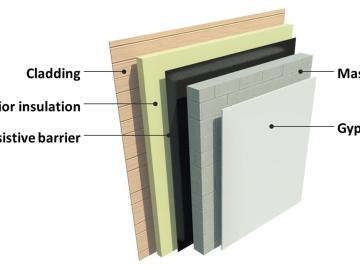

Oak Ridge National Laboratory will lead the 13th international conference on Thermal Performance of the Exterior Envelopes of Whole Buildings XIII on December 5-8 in Clearwater, Florida, an event that attracts building envelope experts from around the world to share state-of-the-art research and technology applications. One topic of interest will be a mold growth index model workshop, explaining the model’s development and application and providing examples of how MGI usage could vary depending on building materials.

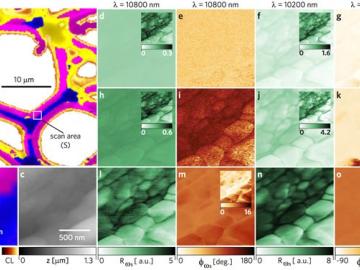

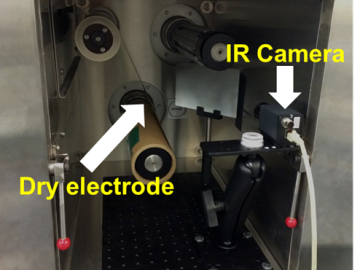

Production run spot checks of materials for lithium-ion batteries and fuel cells could be a thing of the past because of a process developed at Oak Ridge National Laboratory. The infrared/thermal nondestructive evaluation technique invented by a team led by David Wood examines key parameters such as porosity and thickness of the coating in real time without destroying product.