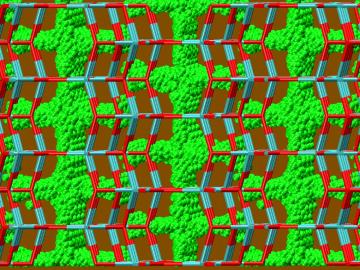

Updated software improves slicing for large-format 3D printing

A novel approach that creates a renewable, leathery material—programmed to remember its shape—may offer a low-cost alternative to conventional conductors for applications in sensors and robotics. To make the bio-based, shape-memory material, Oak Ridge National Laboratory scientists streamlined a solvent-free process that mixes rubber with lignin—the by-product of woody plants used to make biofuels.

Oak Ridge National Laboratory has successfully developed and tested a novel sand casting technique to quickly design complex patterns to fabricate components for industry partner Emrgy Hydro, makers of hydropower devices designed to generate electricity from slow or shallow water flo...