Filter News

Area of Research

News Topics

- (-) Polymers (5)

- (-) Simulation (1)

- 3-D Printing/Advanced Manufacturing (23)

- Artificial Intelligence (1)

- Big Data (1)

- Bioenergy (2)

- Biology (2)

- Biomedical (1)

- Biotechnology (1)

- Buildings (13)

- Chemical Sciences (1)

- Clean Water (4)

- Climate Change (6)

- Composites (9)

- Computer Science (9)

- Coronavirus (2)

- Critical Materials (4)

- Decarbonization (4)

- Energy Storage (21)

- Environment (15)

- Grid (15)

- High-Performance Computing (1)

- Hydropower (2)

- Machine Learning (2)

- Materials (12)

- Materials Science (9)

- Mathematics (1)

- Mercury (1)

- Microscopy (2)

- Nanotechnology (1)

- Net Zero (1)

- Nuclear Energy (1)

- Space Exploration (2)

- Statistics (1)

- Sustainable Energy (27)

- Transportation (26)

Media Contacts

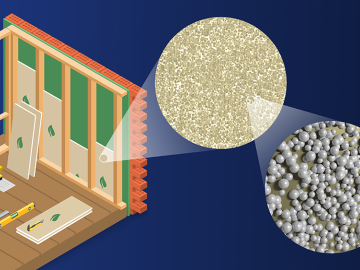

Scientists at ORNL developed a competitive, eco-friendly alternative made without harmful blowing agents.

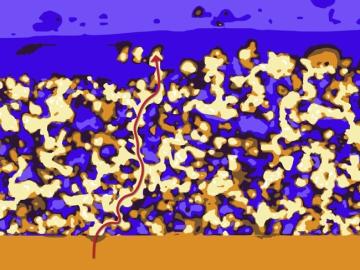

When aging vehicle batteries lack the juice to power your car anymore, they may still hold energy. Yet it’s tough to find new uses for lithium-ion batteries with different makers, ages and sizes. A solution is urgently needed because battery recycling options are scarce.

Oak Ridge National Laboratory scientists designed a recyclable polymer for carbon-fiber composites to enable circular manufacturing of parts that boost energy efficiency in automotive, wind power and aerospace applications.

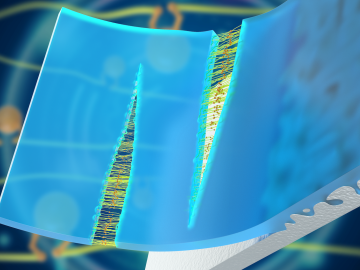

Oak Ridge National Laboratory researchers have developed a thin film, highly conductive solid-state electrolyte made of a polymer and ceramic-based composite for lithium metal batteries.

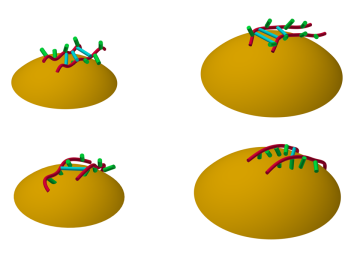

A team of researchers at Oak Ridge National Laboratory have demonstrated that designed synthetic polymers can serve as a high-performance binding material for next-generation lithium-ion batteries.