Filter News

Area of Research

News Topics

- (-) 3-D Printing/Advanced Manufacturing (31)

- (-) Biotechnology (3)

- (-) Clean Water (13)

- Advanced Reactors (13)

- Artificial Intelligence (13)

- Big Data (15)

- Bioenergy (15)

- Biology (17)

- Biomedical (11)

- Buildings (18)

- Chemical Sciences (8)

- Climate Change (21)

- Composites (9)

- Computer Science (39)

- Coronavirus (11)

- Critical Materials (12)

- Cybersecurity (3)

- Decarbonization (8)

- Energy Storage (31)

- Environment (43)

- Exascale Computing (1)

- Frontier (1)

- Fusion (9)

- Grid (20)

- High-Performance Computing (11)

- Hydropower (6)

- Irradiation (2)

- Isotopes (5)

- ITER (3)

- Machine Learning (10)

- Materials (35)

- Materials Science (33)

- Mathematics (1)

- Mercury (3)

- Microscopy (11)

- Molten Salt (5)

- Nanotechnology (12)

- National Security (3)

- Net Zero (1)

- Neutron Science (27)

- Nuclear Energy (18)

- Partnerships (1)

- Physics (4)

- Polymers (9)

- Quantum Computing (4)

- Quantum Science (10)

- Security (1)

- Simulation (6)

- Space Exploration (10)

- Statistics (1)

- Summit (6)

- Sustainable Energy (44)

- Transportation (35)

Media Contacts

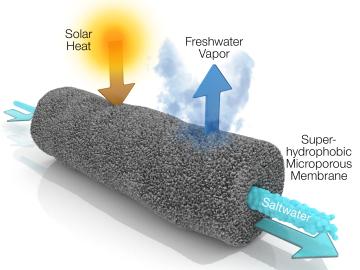

A new method developed at Oak Ridge National Laboratory improves the energy efficiency of a desalination process known as solar-thermal evaporation.

A novel additive manufacturing method developed by researchers at Oak Ridge National Laboratory could be a promising alternative for low-cost, high-quality production of large-scale metal parts with less material waste.

Scientists at Oak Ridge National Laboratory have developed a low-cost, printed, flexible sensor that can wrap around power cables to precisely monitor electrical loads from household appliances to support grid operations.

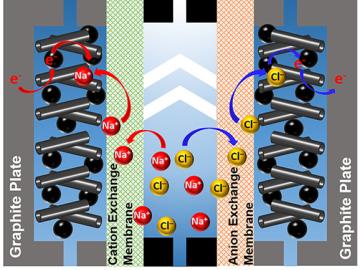

A team of scientists led by Oak Ridge National Laboratory used carbon nanotubes to improve a desalination process that attracts and removes ionic compounds such as salt from water using charged electrodes.

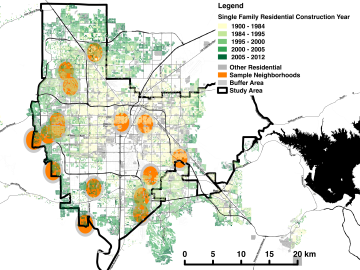

A team led by Oak Ridge National Laboratory has discovered that residents living in arid environments share a desire for water security, which can ultimately benefit entire neighborhoods. Las Vegas, Nevada’s water utility was the first utility in the United States to implement ...

The construction industry may soon benefit from 3D printed molds to make concrete facades, promising lower cost and production time. Researchers at Oak Ridge National Laboratory are evaluating the performance of 3D printed molds used to precast concrete facades in a 42-story buildin...

Oak Ridge National Laboratory scientists have improved a mixture of materials used to 3D print permanent magnets with increased density, which could yield longer lasting, better performing magnets for electric motors, sensors and vehicle applications. Building on previous research, ...