Filter News

Area of Research

News Topics

- (-) Composites (9)

- (-) Irradiation (2)

- (-) Isotopes (5)

- (-) Polymers (9)

- 3-D Printing/Advanced Manufacturing (31)

- Advanced Reactors (13)

- Artificial Intelligence (13)

- Big Data (15)

- Bioenergy (15)

- Biology (17)

- Biomedical (11)

- Biotechnology (3)

- Buildings (18)

- Chemical Sciences (8)

- Clean Water (13)

- Climate Change (21)

- Computer Science (39)

- Coronavirus (11)

- Critical Materials (12)

- Cybersecurity (3)

- Decarbonization (8)

- Energy Storage (31)

- Environment (43)

- Exascale Computing (1)

- Frontier (1)

- Fusion (9)

- Grid (20)

- High-Performance Computing (11)

- Hydropower (6)

- ITER (3)

- Machine Learning (10)

- Materials (35)

- Materials Science (33)

- Mathematics (1)

- Mercury (3)

- Microscopy (11)

- Molten Salt (5)

- Nanotechnology (12)

- National Security (3)

- Net Zero (1)

- Neutron Science (27)

- Nuclear Energy (18)

- Partnerships (1)

- Physics (4)

- Quantum Computing (4)

- Quantum Science (10)

- Security (1)

- Simulation (6)

- Space Exploration (10)

- Statistics (1)

- Summit (6)

- Sustainable Energy (44)

- Transportation (35)

Media Contacts

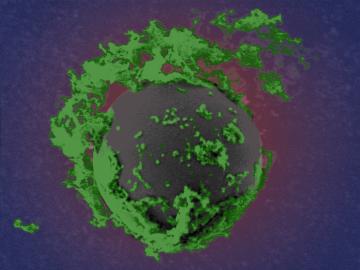

Oak Ridge National Laboratory scientists ingeniously created a sustainable, soft material by combining rubber with woody reinforcements and incorporating “smart” linkages between the components that unlock on demand.

Electric vehicles can drive longer distances if their lithium-ion batteries deliver more energy in a lighter package. A prime weight-loss candidate is the current collector, a component that often adds 10% to the weight of a battery cell without contributing energy.

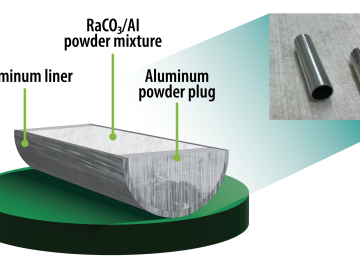

Oak Ridge National Laboratory researchers have developed a method to simplify one step of radioisotope production — and it’s faster and safer.

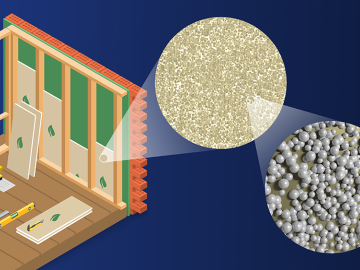

Scientists at ORNL developed a competitive, eco-friendly alternative made without harmful blowing agents.

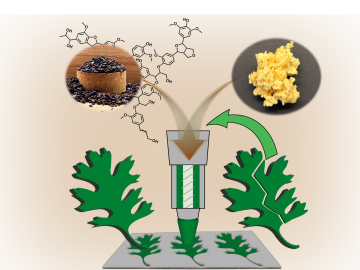

The presence of minerals called ash in plants makes little difference to the fitness of new naturally derived compound materials designed for additive manufacturing, an Oak Ridge National Laboratory-led team found.

Oak Ridge National Laboratory scientists designed a recyclable polymer for carbon-fiber composites to enable circular manufacturing of parts that boost energy efficiency in automotive, wind power and aerospace applications.

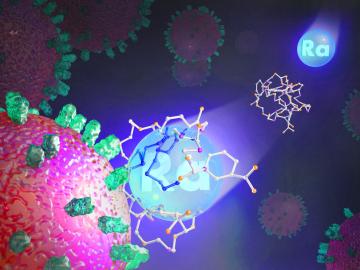

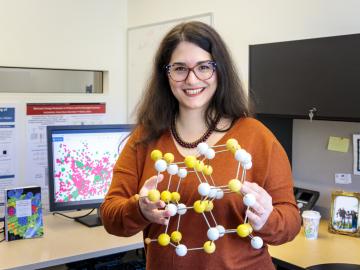

Researchers at ORNL explored radium’s chemistry to advance cancer treatments using ionizing radiation.

To advance sensor technologies, Oak Ridge National Laboratory researchers studied piezoelectric materials, which convert mechanical stress into electrical energy, to see how they could handle bombardment with energetic neutrons.

A research team at Oak Ridge National Laboratory have 3D printed a thermal protection shield, or TPS, for a capsule that will launch with the Cygnus cargo spacecraft as part of the supply mission to the International Space Station.

An Oak Ridge National Laboratory researcher has invented a version of an isotope-separating device that can withstand extreme environments, including radiation and chemical solvents.