Filter News

Area of Research

News Topics

- (-) Composites (9)

- (-) Mercury (3)

- (-) Polymers (9)

- 3-D Printing/Advanced Manufacturing (31)

- Advanced Reactors (13)

- Artificial Intelligence (13)

- Big Data (15)

- Bioenergy (15)

- Biology (17)

- Biomedical (11)

- Biotechnology (3)

- Buildings (18)

- Chemical Sciences (8)

- Clean Water (13)

- Climate Change (21)

- Computer Science (39)

- Coronavirus (11)

- Critical Materials (12)

- Cybersecurity (3)

- Decarbonization (8)

- Energy Storage (31)

- Environment (43)

- Exascale Computing (1)

- Frontier (1)

- Fusion (9)

- Grid (20)

- High-Performance Computing (11)

- Hydropower (6)

- Irradiation (2)

- Isotopes (5)

- ITER (3)

- Machine Learning (10)

- Materials (35)

- Materials Science (33)

- Mathematics (1)

- Microscopy (11)

- Molten Salt (5)

- Nanotechnology (12)

- National Security (3)

- Net Zero (1)

- Neutron Science (27)

- Nuclear Energy (18)

- Partnerships (1)

- Physics (4)

- Quantum Computing (4)

- Quantum Science (10)

- Security (1)

- Simulation (6)

- Space Exploration (10)

- Statistics (1)

- Summit (6)

- Sustainable Energy (44)

- Transportation (35)

Media Contacts

Oak Ridge National Laboratory scientists have discovered a cost-effective way to significantly improve the mechanical performance of common polymer nanocomposite materials.

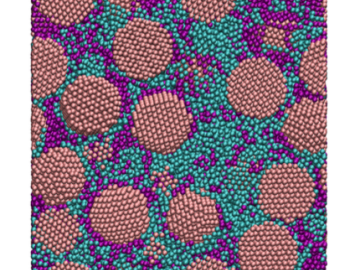

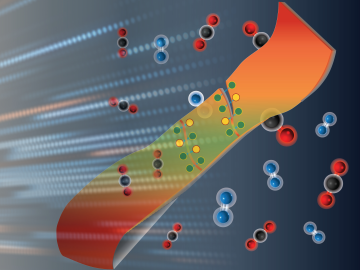

Oak Ridge National Laboratory researchers have developed a thin film, highly conductive solid-state electrolyte made of a polymer and ceramic-based composite for lithium metal batteries.

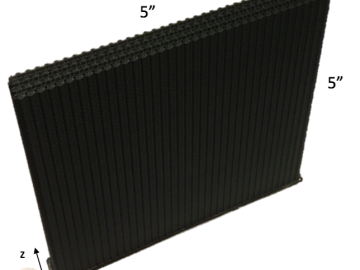

A team including Oak Ridge National Laboratory and University of Tennessee researchers demonstrated a novel 3D printing approach called Z-pinning that can increase the material’s strength and toughness by more than three and a half times compared to conventional additive manufacturing processes.

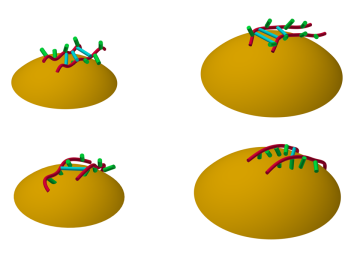

A team of researchers at Oak Ridge National Laboratory have demonstrated that designed synthetic polymers can serve as a high-performance binding material for next-generation lithium-ion batteries.

Biologists from Oak Ridge National Laboratory and the Smithsonian Environmental Research Center have confirmed that microorganisms called methanogens can transform mercury into the neurotoxin methylmercury with varying efficiency across species.

An Oak Ridge National Laboratory–led team has developed super-stretchy polymers with amazing self-healing abilities that could lead to longer-lasting consumer products.

Scientists at Oak Ridge National Laboratory have conducted a series of breakthrough experimental and computational studies that cast doubt on a 40-year-old theory describing how polymers in plastic materials behave during processing.

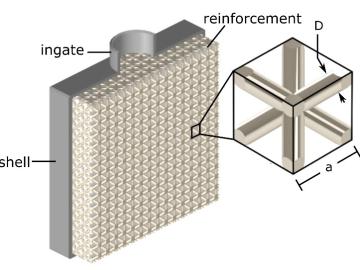

A new manufacturing method created by Oak Ridge National Laboratory and Rice University combines 3D printing with traditional casting to produce damage-tolerant components composed of multiple materials. Composite components made by pouring an aluminum alloy over a printed steel lattice showed an order of magnitude greater damage tolerance than aluminum alone.

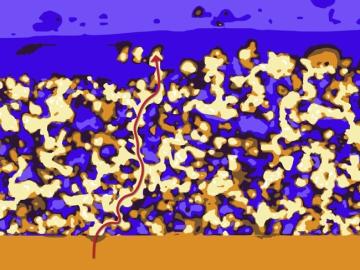

An Oak Ridge National Laboratory study is providing an unprecedented watershed-scale understanding of mercury in soils and sediments. Researchers focused on evaluating mercury and soil properties along the banks of a mercury-contaminated stream in Oak Ridge, Tenn., sampling 145 loca...