Filter News

Area of Research

News Topics

- (-) Cybersecurity (3)

- (-) Fusion (9)

- (-) Net Zero (1)

- (-) Polymers (9)

- 3-D Printing/Advanced Manufacturing (31)

- Advanced Reactors (13)

- Artificial Intelligence (13)

- Big Data (15)

- Bioenergy (15)

- Biology (17)

- Biomedical (11)

- Biotechnology (3)

- Buildings (18)

- Chemical Sciences (8)

- Clean Water (13)

- Climate Change (21)

- Composites (9)

- Computer Science (39)

- Coronavirus (11)

- Critical Materials (12)

- Decarbonization (8)

- Energy Storage (31)

- Environment (43)

- Exascale Computing (1)

- Frontier (1)

- Grid (20)

- High-Performance Computing (11)

- Hydropower (6)

- Irradiation (2)

- Isotopes (5)

- ITER (3)

- Machine Learning (10)

- Materials (35)

- Materials Science (33)

- Mathematics (1)

- Mercury (3)

- Microscopy (11)

- Molten Salt (5)

- Nanotechnology (12)

- National Security (3)

- Neutron Science (27)

- Nuclear Energy (18)

- Partnerships (1)

- Physics (4)

- Quantum Computing (4)

- Quantum Science (10)

- Security (1)

- Simulation (6)

- Space Exploration (10)

- Statistics (1)

- Summit (6)

- Sustainable Energy (44)

- Transportation (35)

Media Contacts

Oak Ridge National Laboratory scientists ingeniously created a sustainable, soft material by combining rubber with woody reinforcements and incorporating “smart” linkages between the components that unlock on demand.

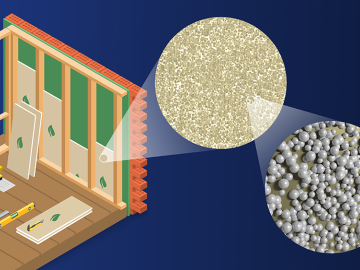

Scientists at ORNL developed a competitive, eco-friendly alternative made without harmful blowing agents.

Oak Ridge National Laboratory scientists designed a recyclable polymer for carbon-fiber composites to enable circular manufacturing of parts that boost energy efficiency in automotive, wind power and aerospace applications.

Oak Ridge National Laboratory researchers have created a technology that more realistically emulates user activities to improve cyber testbeds and ultimately prevent cyberattacks.

Staff at Oak Ridge National Laboratory organized transport for a powerful component that is critical to the world’s largest experiment, the international ITER project.

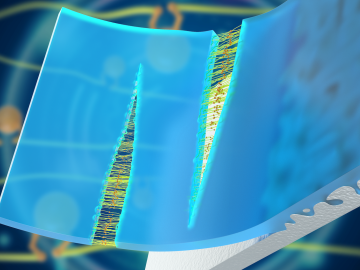

Equipment and expertise from Oak Ridge National Laboratory will allow scientists studying fusion energy and technologies to acquire crucial data during landmark fusion experiments in Europe.

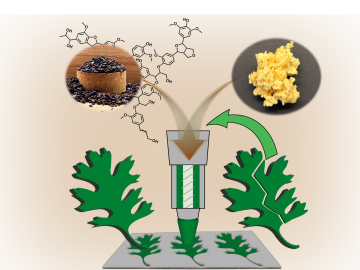

A research team led by Oak Ridge National Laboratory bioengineered a microbe to efficiently turn waste into itaconic acid, an industrial chemical used in plastics and paints.

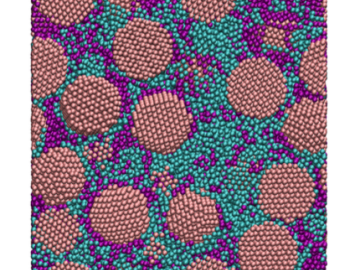

Oak Ridge National Laboratory scientists have discovered a cost-effective way to significantly improve the mechanical performance of common polymer nanocomposite materials.

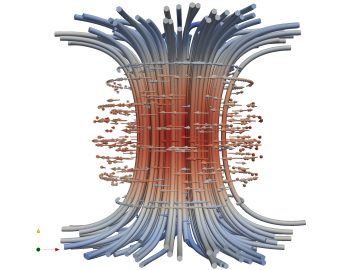

Combining expertise in physics, applied math and computing, Oak Ridge National Laboratory scientists are expanding the possibilities for simulating electromagnetic fields that underpin phenomena in materials design and telecommunications.