Filter News

Area of Research

News Topics

- (-) Molten Salt (5)

- 3-D Printing/Advanced Manufacturing (30)

- Advanced Reactors (13)

- Artificial Intelligence (13)

- Big Data (15)

- Bioenergy (15)

- Biology (17)

- Biomedical (11)

- Biotechnology (3)

- Buildings (17)

- Chemical Sciences (7)

- Clean Water (13)

- Climate Change (20)

- Composites (9)

- Computer Science (39)

- Coronavirus (11)

- Critical Materials (11)

- Cybersecurity (3)

- Decarbonization (7)

- Energy Storage (30)

- Environment (43)

- Exascale Computing (1)

- Frontier (1)

- Fusion (9)

- Grid (20)

- High-Performance Computing (11)

- Hydropower (6)

- Irradiation (2)

- Isotopes (5)

- ITER (3)

- Machine Learning (10)

- Materials (34)

- Materials Science (31)

- Mathematics (1)

- Mercury (3)

- Microscopy (11)

- Nanotechnology (12)

- National Security (3)

- Net Zero (1)

- Neutron Science (27)

- Nuclear Energy (18)

- Partnerships (1)

- Physics (4)

- Polymers (8)

- Quantum Computing (4)

- Quantum Science (10)

- Security (1)

- Simulation (6)

- Space Exploration (10)

- Statistics (1)

- Summit (6)

- Sustainable Energy (42)

- Transportation (35)

Media Contacts

In the 1960s, Oak Ridge National Laboratory's four-year Molten Salt Reactor Experiment tested the viability of liquid fuel reactors for commercial power generation. Results from that historic experiment recently became the basis for the first-ever molten salt reactor benchmark.

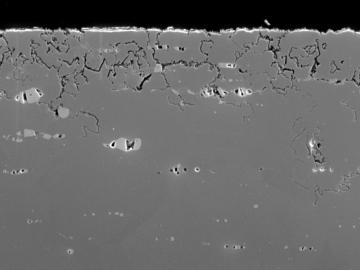

Oak Ridge National Laboratory scientists analyzed more than 50 years of data showing puzzlingly inconsistent trends about corrosion of structural alloys in molten salts and found one factor mattered most—salt purity.

Scientists from Oak Ridge National Laboratory performed a corrosion test in a neutron radiation field to support the continued development of molten salt reactors.

Experts focused on the future of nuclear technology will gather at Oak Ridge National Laboratory for the fourth annual Molten Salt Reactor Workshop on October 3–4.

Oak Ridge National Laboratory has developed a salt purification lab to study the viability of using liquid salt that contains lithium fluoride and beryllium fluoride, known as FLiBe, to cool molten salt reactors, or MSRs. Multiple American companies developing advanced reactor technol...