Filter News

Area of Research

News Topics

- (-) Buildings (17)

- (-) Materials (34)

- 3-D Printing/Advanced Manufacturing (30)

- Advanced Reactors (13)

- Artificial Intelligence (13)

- Big Data (15)

- Bioenergy (15)

- Biology (17)

- Biomedical (11)

- Biotechnology (3)

- Chemical Sciences (7)

- Clean Water (13)

- Climate Change (20)

- Composites (9)

- Computer Science (39)

- Coronavirus (11)

- Critical Materials (11)

- Cybersecurity (3)

- Decarbonization (7)

- Energy Storage (30)

- Environment (43)

- Exascale Computing (1)

- Frontier (1)

- Fusion (9)

- Grid (20)

- High-Performance Computing (11)

- Hydropower (6)

- Irradiation (2)

- Isotopes (5)

- ITER (3)

- Machine Learning (10)

- Materials Science (31)

- Mathematics (1)

- Mercury (3)

- Microscopy (11)

- Molten Salt (5)

- Nanotechnology (12)

- National Security (3)

- Net Zero (1)

- Neutron Science (27)

- Nuclear Energy (18)

- Partnerships (1)

- Physics (4)

- Polymers (8)

- Quantum Computing (4)

- Quantum Science (10)

- Security (1)

- Simulation (6)

- Space Exploration (10)

- Statistics (1)

- Summit (6)

- Sustainable Energy (42)

- Transportation (35)

Media Contacts

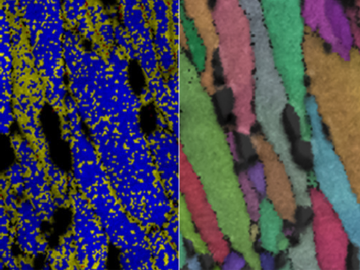

ORNL researchers have identified a mechanism in a 3D-printed alloy – termed “load shuffling” — that could enable the design of better-performing lightweight materials for vehicles.

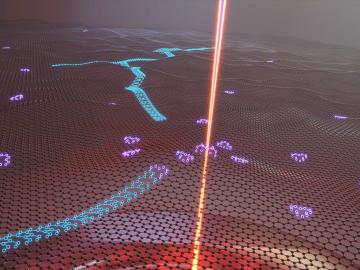

Oak Ridge National Laboratory researchers serendipitously discovered when they automated the beam of an electron microscope to precisely drill holes in the atomically thin lattice of graphene, the drilled holes closed up.

Oak Ridge National Laboratory scientists designed a recyclable polymer for carbon-fiber composites to enable circular manufacturing of parts that boost energy efficiency in automotive, wind power and aerospace applications.

Researchers at ORNL have developed a tool that provides accurate measurements and positioning directions to those installing energy-efficient panels over existing building exteriors. This method will decrease installation time and cost by more than 25%.

Researchers at ORNL have developed an online tool that offers industrial plants an easier way to track and download information about their energy footprint and carbon emissions.

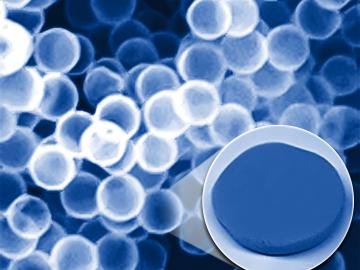

ORNL researchers demonstrated a process for producing a moisture-stable, lightweight thermal insulation material using hollow silica particles, or HSPs.

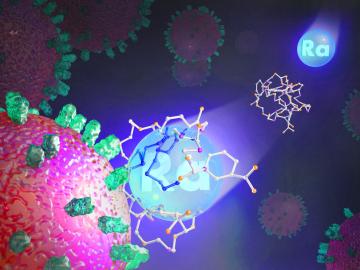

Researchers at ORNL explored radium’s chemistry to advance cancer treatments using ionizing radiation.

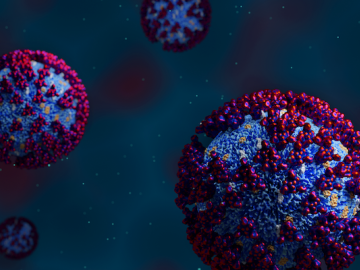

Researchers from ORNL, the University of Tennessee at Chattanooga and Tuskegee University used mathematics to predict which areas of the SARS-CoV-2 spike protein are most likely to mutate.

Oak Ridge National Laboratory researchers demonstrated that microchannel heat exchangers in heating, ventilation and air conditioning units can keep refrigerants evenly and continually distributed by inserting a device called a piezoelectric-driven

Researchers at Oak Ridge National Laboratory and Momentum Technologies have piloted an industrial-scale process for recycling valuable materials in the millions of tons of e-waste generated annually in the United States.