Filter News

Area of Research

- (-) Clean Energy (38)

- (-) Computer Science (5)

- (-) Materials (11)

- (-) Nuclear Science and Technology (5)

- Advanced Manufacturing (11)

- Biology and Environment (5)

- Building Technologies (1)

- Computational Engineering (1)

- Electricity and Smart Grid (1)

- Fusion and Fission (2)

- Fusion Energy (8)

- Isotopes (3)

- Materials for Computing (3)

- National Security (3)

- Neutron Science (1)

- Nuclear Systems Modeling, Simulation and Validation (1)

- Quantum information Science (1)

- Sensors and Controls (1)

- Supercomputing (4)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (26)

- (-) Advanced Reactors (5)

- (-) Coronavirus (3)

- (-) Fusion (3)

- (-) Grid (16)

- (-) Isotopes (3)

- (-) Machine Learning (5)

- (-) Physics (2)

- Artificial Intelligence (5)

- Big Data (4)

- Bioenergy (2)

- Biology (2)

- Biomedical (3)

- Biotechnology (1)

- Buildings (13)

- Chemical Sciences (4)

- Clean Water (4)

- Climate Change (6)

- Composites (9)

- Computer Science (17)

- Critical Materials (8)

- Decarbonization (4)

- Energy Storage (22)

- Environment (16)

- High-Performance Computing (2)

- Hydropower (2)

- Materials (22)

- Materials Science (23)

- Mathematics (1)

- Mercury (1)

- Microscopy (6)

- Molten Salt (4)

- Nanotechnology (8)

- Net Zero (1)

- Neutron Science (6)

- Nuclear Energy (13)

- Polymers (7)

- Quantum Computing (1)

- Quantum Science (2)

- Simulation (1)

- Space Exploration (4)

- Statistics (1)

- Sustainable Energy (27)

- Transportation (27)

Media Contacts

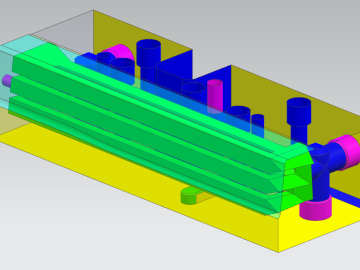

Researchers demonstrated that an additively manufactured hot stamping die can withstand up to 25,000 usage cycles, proving that this technique is a viable solution for production.

A team including Oak Ridge National Laboratory and University of Tennessee researchers demonstrated a novel 3D printing approach called Z-pinning that can increase the material’s strength and toughness by more than three and a half times compared to conventional additive manufacturing processes.

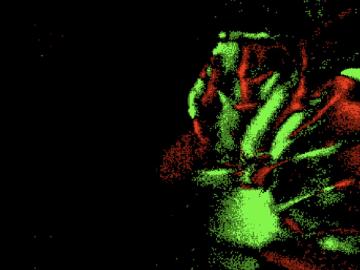

Oak Ridge National Laboratory is training next-generation cameras called dynamic vision sensors, or DVS, to interpret live information—a capability that has applications in robotics and could improve autonomous vehicle sensing.

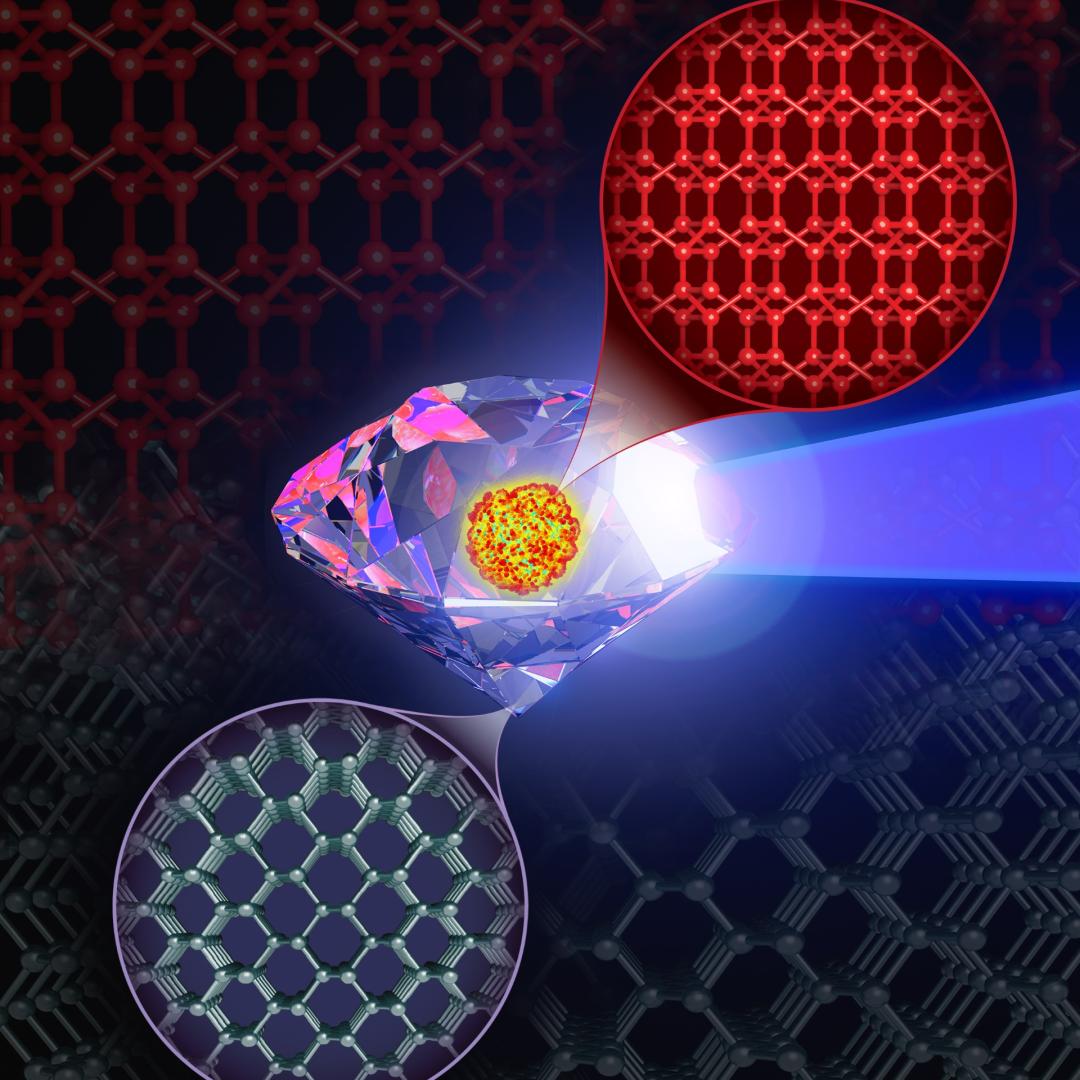

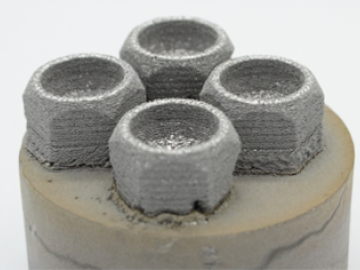

Using additive manufacturing, scientists experimenting with tungsten at Oak Ridge National Laboratory hope to unlock new potential of the high-performance heat-transferring material used to protect components from the plasma inside a fusion reactor. Fusion requires hydrogen isotopes to reach millions of degrees.

Researchers at Oak Ridge National Laboratory are taking inspiration from neural networks to create computers that mimic the human brain—a quickly growing field known as neuromorphic computing.

For the first time, Oak Ridge National Laboratory has completed testing of nuclear fuels using MiniFuel, an irradiation vehicle that allows for rapid experimentation.

A study led by Oak Ridge National Laboratory explored the interface between the Department of Veterans Affairs’ healthcare data system and the data itself to detect the likelihood of errors and designed an auto-surveillance tool

Scientists have discovered a way to alter heat transport in thermoelectric materials, a finding that may ultimately improve energy efficiency as the materials

Scientists at Oak Ridge National Laboratory have developed a low-cost, printed, flexible sensor that can wrap around power cables to precisely monitor electrical loads from household appliances to support grid operations.

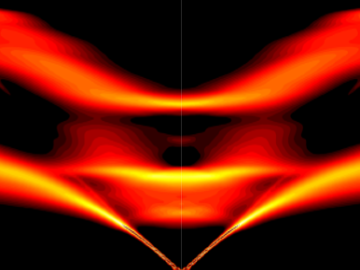

Scientists have tested a novel heat-shielding graphite foam, originally created at Oak Ridge National Laboratory, at Germany’s Wendelstein 7-X stellarator with promising results for use in plasma-facing components of fusion reactors.