Filter News

Area of Research

- Biology and Environment (6)

- Clean Energy (44)

- Computational Biology (1)

- Computational Engineering (1)

- Computer Science (6)

- Electricity and Smart Grid (1)

- Fusion and Fission (1)

- Fusion Energy (1)

- Materials (22)

- Materials for Computing (7)

- National Security (5)

- Neutron Science (5)

- Quantum information Science (3)

- Sensors and Controls (1)

- Supercomputing (12)

- Transportation Systems (2)

News Type

News Topics

- (-) Chemical Sciences (9)

- (-) Coronavirus (11)

- (-) Decarbonization (8)

- (-) Grid (20)

- (-) Machine Learning (10)

- (-) Microscopy (11)

- (-) Nanotechnology (12)

- (-) Quantum Science (10)

- (-) Summit (6)

- (-) Transportation (35)

- 3-D Printing/Advanced Manufacturing (31)

- Advanced Reactors (13)

- Artificial Intelligence (13)

- Big Data (16)

- Bioenergy (15)

- Biology (17)

- Biomedical (11)

- Biotechnology (3)

- Buildings (19)

- Clean Water (13)

- Climate Change (22)

- Composites (9)

- Computer Science (39)

- Critical Materials (12)

- Cybersecurity (3)

- Energy Storage (31)

- Environment (43)

- Exascale Computing (1)

- Frontier (1)

- Fusion (9)

- High-Performance Computing (11)

- Hydropower (6)

- Irradiation (2)

- Isotopes (5)

- ITER (3)

- Materials (35)

- Materials Science (33)

- Mathematics (1)

- Mercury (3)

- Molten Salt (5)

- National Security (3)

- Net Zero (1)

- Neutron Science (27)

- Nuclear Energy (19)

- Partnerships (1)

- Physics (4)

- Polymers (9)

- Quantum Computing (4)

- Security (1)

- Simulation (7)

- Space Exploration (10)

- Statistics (1)

- Sustainable Energy (44)

Media Contacts

Oak Ridge National Laboratory scientists designed a recyclable polymer for carbon-fiber composites to enable circular manufacturing of parts that boost energy efficiency in automotive, wind power and aerospace applications.

Researchers from ORNL, the University of Tennessee at Chattanooga and Tuskegee University used mathematics to predict which areas of the SARS-CoV-2 spike protein are most likely to mutate.

To further the potential benefits of the nation’s hydropower resources, researchers at Oak Ridge National Laboratory have developed and maintain a comprehensive water energy digital platform called HydroSource.

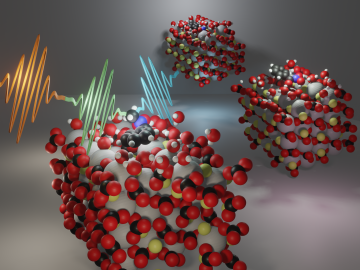

Researchers at Oak Ridge National Laboratory are using state-of-the-art methods to shed light on chemical separations needed to recover rare-earth elements and secure critical materials for clean energy technologies.

Oak Ridge National Laboratory researchers determined that for every 5 miles per hour that drivers travel over a 50-mph speed limit, fuel economy decreases by 7% and equates to paying an extra 28 cents per gallon at current.

Researchers at Oak Ridge National Laboratory have empirically quantified the shifts in routine daytime activities, such as getting a morning coffee or takeaway dinner, following safer at home orders during the early days of the COVID-19 pandemic.

An Oak Ridge National Laboratory team developed a novel technique using sensors to monitor seismic and acoustic activity and machine learning to differentiate operational activities at facilities from “noise” in the recorded data.

A new Department of Energy report produced by Oak Ridge National Laboratory identifies several supply chain must-haves in maintaining the pivotal role hydropower will play in decarbonizing the nation’s grid.

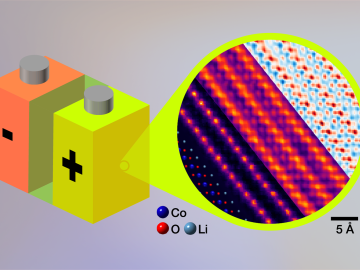

Several electrolyte and thin-film coating technologies, developed at Oak Ridge National Laboratory, have been licensed by BTRY, a battery technology company based in Virginia, to make batteries with increased energy density, at lower cost, and with an improved safety profile in crashes.

Oak Ridge National Laboratory researchers demonstrated an electron microscopy technique for imaging lithium in energy storage materials, such as lithium ion batteries, at the atomic scale.