Filter News

Area of Research

- (-) Fusion and Fission (5)

- (-) Supercomputing (11)

- Advanced Manufacturing (22)

- Biology and Environment (14)

- Building Technologies (1)

- Clean Energy (140)

- Fusion Energy (1)

- Materials (36)

- Materials for Computing (9)

- National Security (4)

- Neutron Science (11)

- Nuclear Science and Technology (4)

- Transportation Systems (2)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (7)

- (-) Transportation (8)

- Advanced Reactors (7)

- Artificial Intelligence (36)

- Big Data (19)

- Bioenergy (10)

- Biology (12)

- Biomedical (18)

- Biotechnology (2)

- Buildings (5)

- Chemical Sciences (9)

- Climate Change (17)

- Composites (1)

- Computer Science (95)

- Coronavirus (14)

- Critical Materials (4)

- Cybersecurity (8)

- Decarbonization (7)

- Energy Storage (11)

- Environment (22)

- Exascale Computing (23)

- Fossil Energy (1)

- Frontier (29)

- Fusion (23)

- Grid (7)

- High-Performance Computing (39)

- Isotopes (2)

- ITER (6)

- Machine Learning (14)

- Materials (16)

- Materials Science (19)

- Mathematics (1)

- Microscopy (8)

- Molten Salt (1)

- Nanotechnology (12)

- National Security (8)

- Net Zero (2)

- Neutron Science (14)

- Nuclear Energy (30)

- Partnerships (4)

- Physics (8)

- Polymers (2)

- Quantum Computing (19)

- Quantum Science (24)

- Security (5)

- Simulation (17)

- Software (1)

- Space Exploration (3)

- Summit (42)

- Sustainable Energy (13)

Media Contacts

To support the development of a revolutionary new open fan engine architecture for the future of flight, GE Aerospace has run simulations using the world’s fastest supercomputer capable of crunching data in excess of exascale speed, or more than a quintillion calculations per second.

ORNL and the Tennessee Valley Authority, or TVA, are joining forces to advance decarbonization technologies from discovery through deployment through a new memorandum of understanding, or MOU.

The daily traffic congestion along the streets and interstate lanes of Chattanooga could be headed the way of the horse and buggy with help from ORNL researchers.

Four first-of-a-kind 3D-printed fuel assembly brackets, produced at the Department of Energy’s Manufacturing Demonstration Facility at Oak Ridge National Laboratory, have been installed and are now under routine operating

Twenty-seven ORNL researchers Zoomed into 11 middle schools across Tennessee during the annual Engineers Week in February. East Tennessee schools throughout Oak Ridge and Roane, Sevier, Blount and Loudon counties participated, with three West Tennessee schools joining in.

As program manager for the Department of Energy’s Oak Ridge National Laboratory’s Package Testing Program, Oscar Martinez enjoys finding and fixing technical issues.

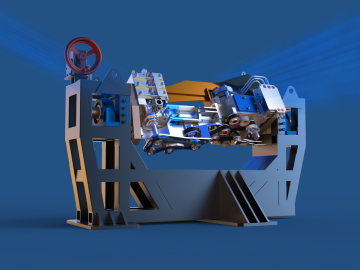

In the quest for advanced vehicles with higher energy efficiency and ultra-low emissions, ORNL researchers are accelerating a research engine that gives scientists and engineers an unprecedented view inside the atomic-level workings of combustion engines in real time.

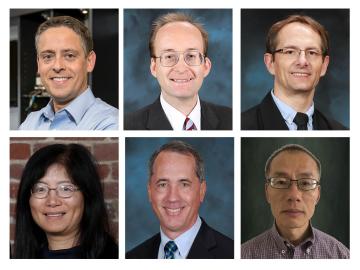

Six scientists at the Department of Energy’s Oak Ridge National Laboratory were named Battelle Distinguished Inventors, in recognition of obtaining 14 or more patents during their careers at the lab.

The annual Director's Awards recognized four individuals and teams including awards for leadership in quantum simulation development and application on high-performance computing platforms, and revolutionary advancements in the area of microbial

The Transformational Challenge Reactor, or TCR, a microreactor built using 3D printing and other new advanced technologies, could be operational by 2024.