Filter News

Area of Research

- (-) Advanced Manufacturing (7)

- (-) Supercomputing (26)

- Biology and Environment (13)

- Clean Energy (107)

- Electricity and Smart Grid (1)

- Functional Materials for Energy (2)

- Fusion and Fission (9)

- Fusion Energy (8)

- Isotope Development and Production (1)

- Isotopes (7)

- Materials (96)

- Materials Characterization (2)

- Materials for Computing (19)

- Materials Under Extremes (1)

- National Security (5)

- Neutron Science (24)

- Nuclear Science and Technology (16)

- Nuclear Systems Modeling, Simulation and Validation (1)

- Transportation Systems (2)

News Topics

- (-) Advanced Reactors (2)

- (-) Materials (21)

- (-) Polymers (2)

- (-) Space Exploration (4)

- (-) Transportation (6)

- 3-D Printing/Advanced Manufacturing (25)

- Artificial Intelligence (37)

- Big Data (19)

- Bioenergy (9)

- Biology (11)

- Biomedical (17)

- Biotechnology (2)

- Buildings (4)

- Chemical Sciences (5)

- Climate Change (17)

- Composites (3)

- Computer Science (95)

- Coronavirus (14)

- Critical Materials (3)

- Cybersecurity (8)

- Decarbonization (5)

- Energy Storage (8)

- Environment (21)

- Exascale Computing (22)

- Frontier (28)

- Fusion (2)

- Grid (5)

- High-Performance Computing (38)

- Isotopes (1)

- Machine Learning (15)

- Materials Science (21)

- Mathematics (1)

- Microscopy (7)

- Molten Salt (1)

- Nanotechnology (11)

- National Security (8)

- Net Zero (1)

- Neutron Science (15)

- Nuclear Energy (5)

- Partnerships (1)

- Physics (7)

- Quantum Computing (19)

- Quantum Science (24)

- Security (5)

- Simulation (14)

- Software (1)

- Summit (42)

- Sustainable Energy (14)

- Transformational Challenge Reactor (1)

Media Contacts

A team of Oak Ridge National Laboratory researchers demonstrated that an additively manufactured hot stamping die – a tool used to create car body components – cooled faster than those produced by conventional manufacturing methods.

The ExOne Company, the global leader in industrial sand and metal 3D printers using binder jetting technology, announced it has reached a commercial license agreement with Oak Ridge National Laboratory to 3D print parts in aluminum-infiltrated boron carbide.

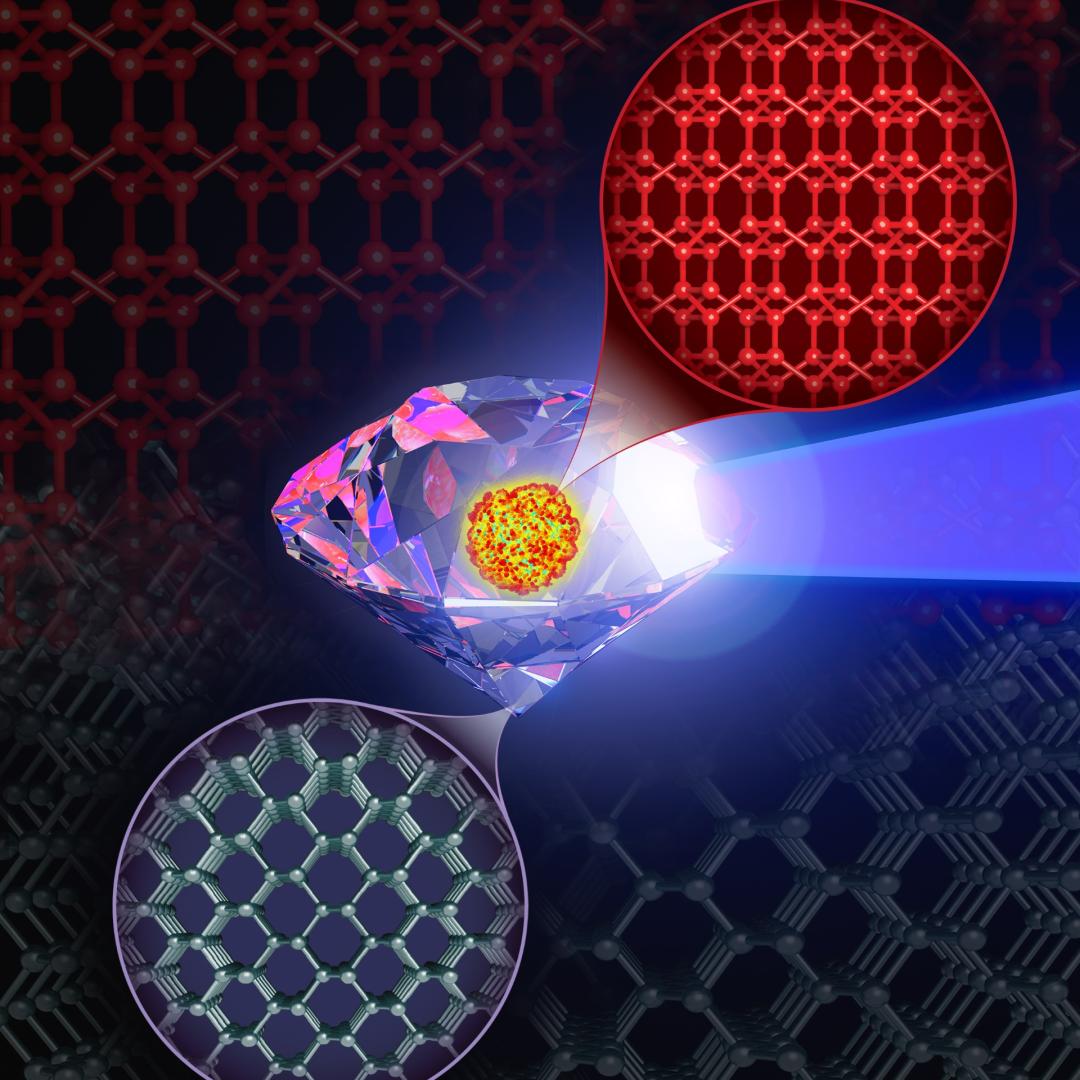

In the quest for advanced vehicles with higher energy efficiency and ultra-low emissions, ORNL researchers are accelerating a research engine that gives scientists and engineers an unprecedented view inside the atomic-level workings of combustion engines in real time.

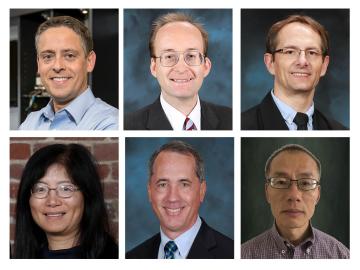

Six scientists at the Department of Energy’s Oak Ridge National Laboratory were named Battelle Distinguished Inventors, in recognition of obtaining 14 or more patents during their careers at the lab.

The annual Director's Awards recognized four individuals and teams including awards for leadership in quantum simulation development and application on high-performance computing platforms, and revolutionary advancements in the area of microbial

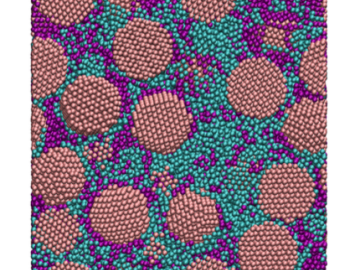

Oak Ridge National Laboratory scientists have discovered a cost-effective way to significantly improve the mechanical performance of common polymer nanocomposite materials.

The type of vehicle that will carry people to the Red Planet is shaping up to be “like a two-story house you’re trying to land on another planet.

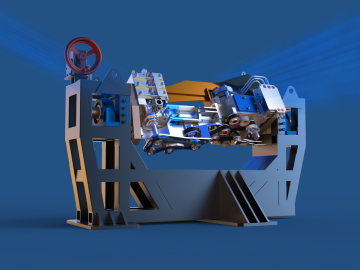

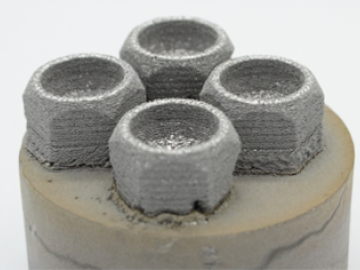

Using additive manufacturing, scientists experimenting with tungsten at Oak Ridge National Laboratory hope to unlock new potential of the high-performance heat-transferring material used to protect components from the plasma inside a fusion reactor. Fusion requires hydrogen isotopes to reach millions of degrees.

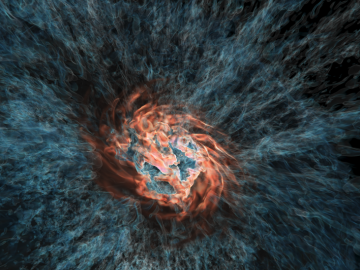

Using the Titan supercomputer at Oak Ridge National Laboratory, a team of astrophysicists created a set of galactic wind simulations of the highest resolution ever performed. The simulations will allow researchers to gather and interpret more accurate, detailed data that elucidates how galactic winds affect the formation and evolution of galaxies.

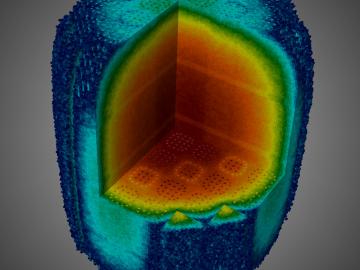

In a step toward advancing small modular nuclear reactor designs, scientists at Oak Ridge National Laboratory have run reactor simulations on ORNL supercomputer Summit with greater-than-expected computational efficiency.