Filter News

Area of Research

- (-) Advanced Manufacturing (22)

- (-) Supercomputing (27)

- Biology and Environment (15)

- Building Technologies (1)

- Clean Energy (80)

- Computer Science (1)

- Fusion and Fission (4)

- Fusion Energy (1)

- Materials (25)

- Materials for Computing (4)

- National Security (3)

- Neutron Science (6)

- Nuclear Science and Technology (4)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (25)

- (-) Exascale Computing (22)

- Advanced Reactors (2)

- Artificial Intelligence (37)

- Big Data (19)

- Bioenergy (9)

- Biology (11)

- Biomedical (17)

- Biotechnology (2)

- Buildings (4)

- Chemical Sciences (5)

- Climate Change (17)

- Composites (3)

- Computer Science (95)

- Coronavirus (14)

- Critical Materials (3)

- Cybersecurity (8)

- Decarbonization (5)

- Energy Storage (8)

- Environment (21)

- Frontier (28)

- Fusion (2)

- Grid (5)

- High-Performance Computing (38)

- Isotopes (1)

- Machine Learning (15)

- Materials (21)

- Materials Science (21)

- Mathematics (1)

- Microscopy (7)

- Molten Salt (1)

- Nanotechnology (11)

- National Security (8)

- Net Zero (1)

- Neutron Science (15)

- Nuclear Energy (5)

- Partnerships (1)

- Physics (7)

- Polymers (2)

- Quantum Computing (19)

- Quantum Science (24)

- Security (5)

- Simulation (14)

- Software (1)

- Space Exploration (4)

- Summit (42)

- Sustainable Energy (14)

- Transformational Challenge Reactor (1)

- Transportation (6)

Media Contacts

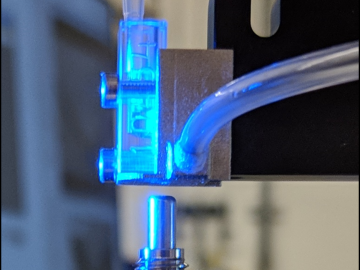

ORNL has licensed two additive manufacturing-related technologies that aim to streamline and ramp up production processes to Knoxville-based Magnum Venus Products, Inc., a global manufacturer of fluid movement and product solutions for industrial applications in composites and adhesives.

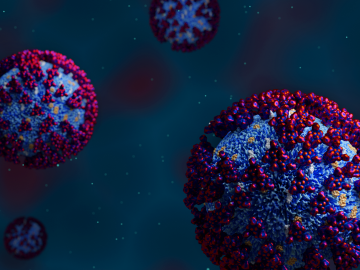

In the race to identify solutions to the COVID-19 pandemic, researchers at the Department of Energy’s Oak Ridge National Laboratory are joining the fight by applying expertise in computational science, advanced manufacturing, data science and neutron science.

OAK RIDGE, Tenn., Feb. 19, 2020 — The U.S. Department of Energy’s Oak Ridge National Laboratory and the Tennessee Valley Authority have signed a memorandum of understanding to evaluate a new generation of flexible, cost-effective advanced nuclear reactors.

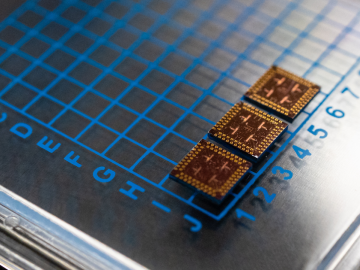

Scientists at have experimentally demonstrated a novel cryogenic, or low temperature, memory cell circuit design based on coupled arrays of Josephson junctions, a technology that may be faster and more energy efficient than existing memory devices.

Researchers across the scientific spectrum crave data, as it is essential to understanding the natural world and, by extension, accelerating scientific progress.

For nearly three decades, scientists and engineers across the globe have worked on the Square Kilometre Array (SKA), a project focused on designing and building the world’s largest radio telescope. Although the SKA will collect enormous amounts of precise astronomical data in record time, scientific breakthroughs will only be possible with systems able to efficiently process that data.

Researchers at Oak Ridge National Laboratory demonstrated that an additively manufactured polymer layer, when applied to carbon fiber reinforced plastic, or CFRP, can serve as an effective protector against aircraft lightning strikes.

Researchers at the Department of Energy’s Oak Ridge National Laboratory have received five 2019 R&D 100 Awards, increasing the lab’s total to 221 since the award’s inception in 1963.

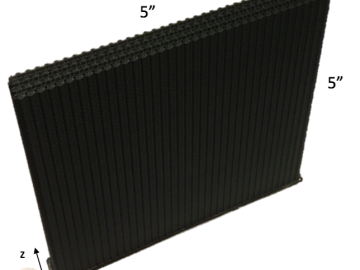

A team including Oak Ridge National Laboratory and University of Tennessee researchers demonstrated a novel 3D printing approach called Z-pinning that can increase the material’s strength and toughness by more than three and a half times compared to conventional additive manufacturing processes.

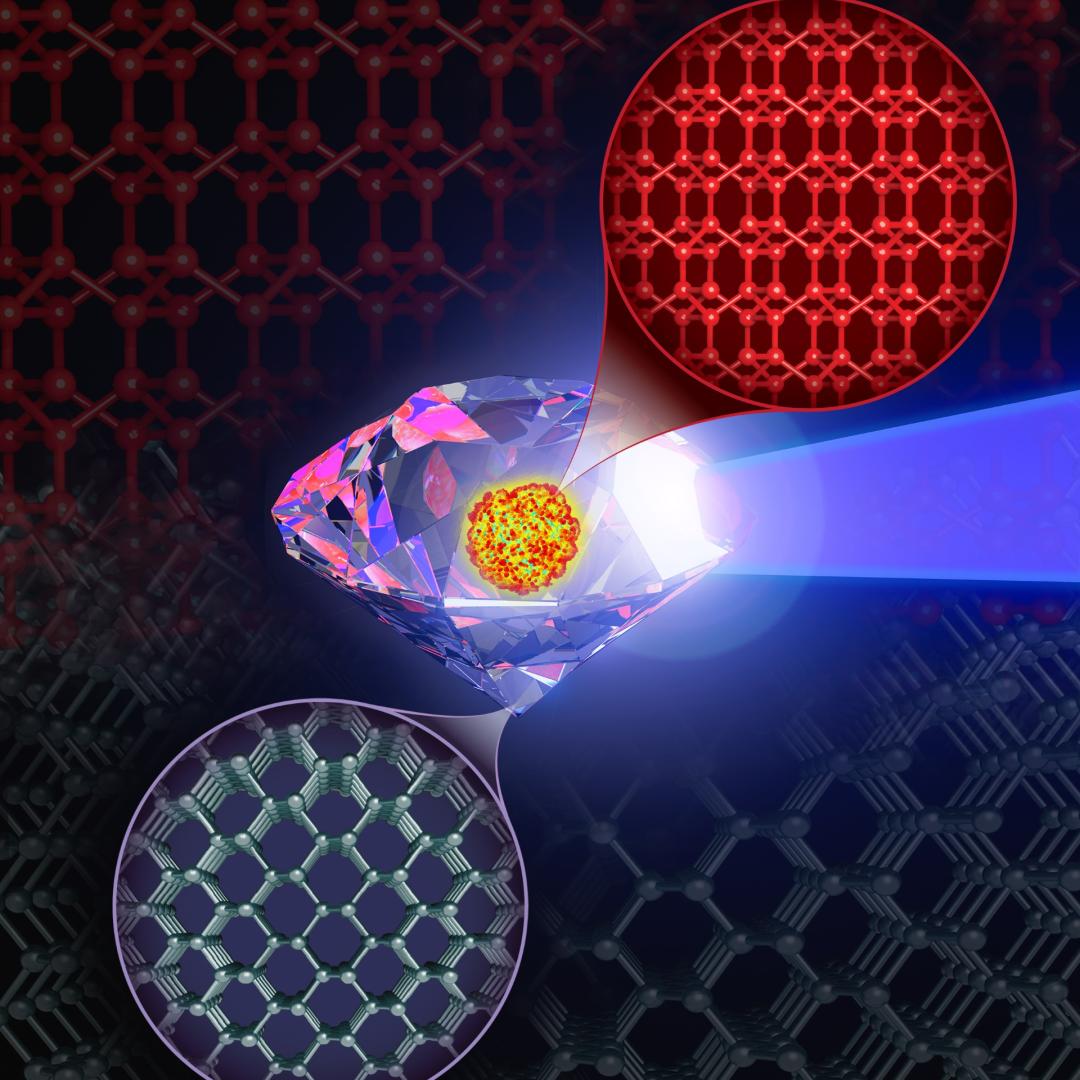

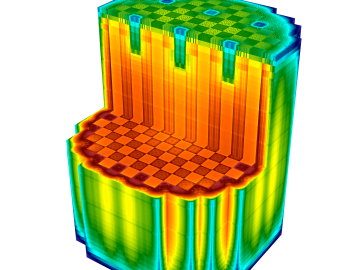

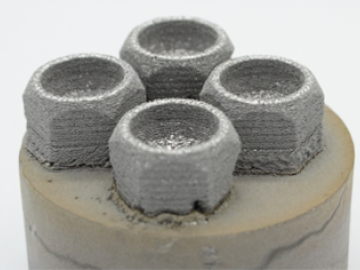

Using additive manufacturing, scientists experimenting with tungsten at Oak Ridge National Laboratory hope to unlock new potential of the high-performance heat-transferring material used to protect components from the plasma inside a fusion reactor. Fusion requires hydrogen isotopes to reach millions of degrees.