Filter News

Area of Research

- (-) Materials for Computing (13)

- (-) National Security (4)

- Advanced Manufacturing (23)

- Biology and Environment (18)

- Building Technologies (1)

- Clean Energy (94)

- Electricity and Smart Grid (1)

- Functional Materials for Energy (2)

- Fusion and Fission (4)

- Fusion Energy (2)

- Isotopes (4)

- Materials (88)

- Materials Characterization (2)

- Materials Under Extremes (1)

- Neutron Science (17)

- Nuclear Science and Technology (4)

- Supercomputing (19)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (6)

- (-) Materials (12)

- Advanced Reactors (1)

- Artificial Intelligence (12)

- Big Data (6)

- Bioenergy (3)

- Biology (5)

- Biomedical (4)

- Biotechnology (1)

- Buildings (1)

- Chemical Sciences (6)

- Climate Change (5)

- Composites (1)

- Computer Science (25)

- Coronavirus (5)

- Cybersecurity (19)

- Decarbonization (2)

- Energy Storage (6)

- Environment (6)

- Exascale Computing (1)

- Frontier (1)

- Fusion (1)

- Grid (6)

- High-Performance Computing (4)

- Irradiation (1)

- Isotopes (1)

- Machine Learning (12)

- Materials Science (19)

- Microscopy (4)

- Nanotechnology (8)

- National Security (35)

- Neutron Science (9)

- Nuclear Energy (6)

- Partnerships (4)

- Physics (1)

- Polymers (6)

- Quantum Computing (1)

- Quantum Science (4)

- Security (12)

- Simulation (1)

- Space Exploration (2)

- Summit (3)

- Sustainable Energy (7)

- Transportation (7)

Media Contacts

Craig Blue, Defense Manufacturing Program Director at the Department of Energy’s Oak Ridge National Laboratory, was recently elected to a two-year term on the Institute for Advanced Composites Manufacturing Innovation Consortium Council, a body of professionals from academia, state governments, and national laboratories that provides strategic direction and oversight to IACMI.

The word “exotic” may not spark thoughts of uranium, but Tyler Spano’s investigations of exotic phases of uranium are bringing new knowledge to the nuclear nonproliferation industry.

ORNL scientists will present new technologies available for licensing during the annual Technology Innovation Showcase. The event is 9 a.m. to 3 p.m. Thursday, June 16, at the Manufacturing Demonstration Facility at ORNL’s Hardin Valley campus.

How an Alvin M. Weinberg Fellow is increasing security for critical infrastructure components

Oak Ridge National Laboratory researchers collaborated with Iowa State University and RJ Lee Group to demonstrate a safe and effective antiviral coating for N95 masks. The coating destroys the COVID-19-causing coronavirus and could enable reuse of masks made from various fabrics.

A study by researchers at the ORNL takes a fresh look at what could become the first step toward a new generation of solar batteries.

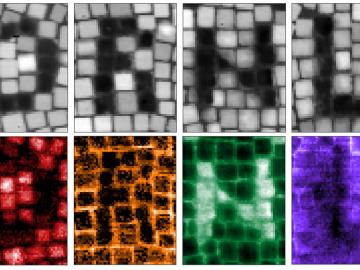

Drilling with the beam of an electron microscope, scientists at ORNL precisely machined tiny electrically conductive cubes that can interact with light and organized them in patterned structures that confine and relay light’s electromagnetic signal.

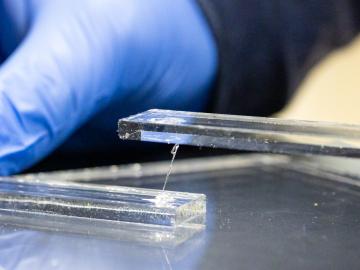

Researchers at ORNL used polymer chemistry to transform a common household plastic into a reusable adhesive with a rare combination of strength and ductility, making it one of the toughest materials ever reported.

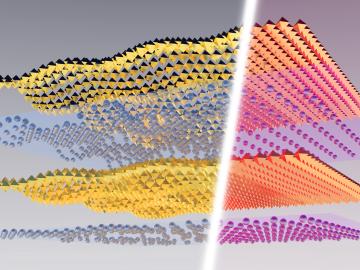

A discovery by Oak Ridge National Laboratory researchers may aid the design of materials that better manage heat.

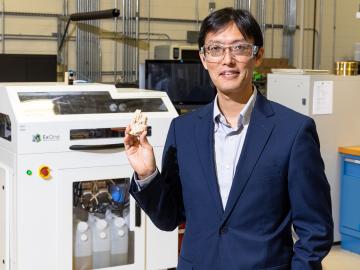

Researchers at ORNL designed a novel polymer to bind and strengthen silica sand for binder jet additive manufacturing, a 3D-printing method used by industries for prototyping and part production.