Filter News

Area of Research

- (-) Clean Energy (522)

- (-) Materials for Computing (36)

- (-) Mathematics (1)

- (-) Neutron Science (190)

- Advanced Manufacturing (34)

- Biological Systems (18)

- Biology and Environment (177)

- Biology and Soft Matter (5)

- Building Technologies (12)

- Chemical and Engineering Materials (4)

- Chemistry and Physics at Interfaces (11)

- Climate and Environmental Systems (14)

- Computational Biology (6)

- Computational Chemistry (5)

- Computational Engineering (5)

- Computer Science (19)

- Data (1)

- Earth Sciences (1)

- Electricity and Smart Grid (3)

- Energy Frontier Research Centers (14)

- Energy Sciences (5)

- Fossil Energy (3)

- Fuel Cycle Science and Technology (3)

- Functional Materials for Energy (16)

- Fusion and Fission (54)

- Fusion Energy (17)

- Geographic Information Science and Technology (3)

- Isotope Development and Production (3)

- Isotopes (35)

- Materials (433)

- Materials Characterization (2)

- Materials Synthesis from Atoms to Systems (13)

- Materials Under Extremes (12)

- National Security (79)

- Neutron Data Analysis and Visualization (4)

- Nuclear Science and Technology (74)

- Nuclear Systems Modeling, Simulation and Validation (3)

- Nuclear Systems Technology (1)

- Quantum Condensed Matter (4)

- Quantum information Science (9)

- Reactor Technology (1)

- Renewable Energy (4)

- Sensors and Controls (5)

- Supercomputing (311)

- Transportation Systems (11)

News Type

News Topics

- 3-D Printing/Advanced Manufacturing (84)

- Advanced Reactors (6)

- Artificial Intelligence (14)

- Big Data (7)

- Bioenergy (30)

- Biology (16)

- Biomedical (18)

- Biotechnology (5)

- Buildings (36)

- Chemical Sciences (20)

- Clean Water (10)

- Climate Change (22)

- Composites (18)

- Computer Science (38)

- Coronavirus (23)

- Critical Materials (9)

- Cybersecurity (9)

- Decarbonization (34)

- Energy Storage (75)

- Environment (59)

- Exascale Computing (2)

- Fossil Energy (3)

- Frontier (3)

- Fusion (2)

- Grid (40)

- High-Performance Computing (8)

- Hydropower (2)

- Isotopes (2)

- Machine Learning (10)

- Materials (54)

- Materials Science (57)

- Mathematics (3)

- Mercury (3)

- Microelectronics (1)

- Microscopy (14)

- Molten Salt (1)

- Nanotechnology (23)

- National Security (8)

- Net Zero (3)

- Neutron Science (102)

- Nuclear Energy (9)

- Partnerships (12)

- Physics (10)

- Polymers (15)

- Quantum Computing (1)

- Quantum Science (10)

- Renewable Energy (1)

- Security (8)

- Simulation (4)

- Space Exploration (6)

- Statistics (1)

- Summit (9)

- Sustainable Energy (70)

- Transformational Challenge Reactor (3)

- Transportation (68)

Media Contacts

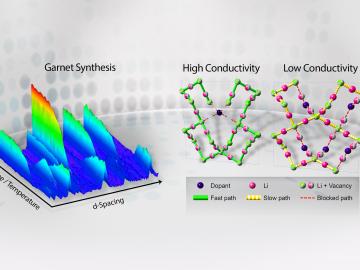

Ensuring a reliable supply of rare earth elements, including four key lanthanides and yttrium, is a major goal of the Critical Materials Institute (https://cmi.ameslab.gov) as these elements are essential to many clean-energy technologies. These include energy-efficient lighting, ...

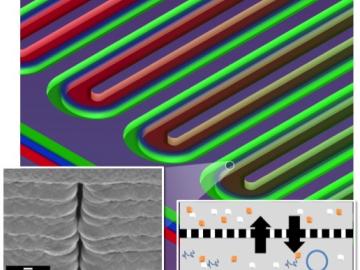

Researchers at the Department of Energy’s Oak Ridge National Laboratory have received six R&D 100 Awards, increasing the lab’s total to 193 since the award’s inception in 1963. The competition, sponsored by R&D Magazine, recognizes advances in the nation’s ...

The Department of Energy’s Oak Ridge National Laboratory, FCA US LLC, and the foundry giant, Nemak of Mexico, are combining their strengths to create lightweight powertrain materials that will help the auto industry speed past the technological