Filter News

Area of Research

- (-) Materials for Computing (7)

- (-) National Security (4)

- Advanced Manufacturing (22)

- Biology and Environment (16)

- Building Technologies (1)

- Clean Energy (142)

- Computer Science (2)

- Electricity and Smart Grid (1)

- Energy Sciences (1)

- Functional Materials for Energy (2)

- Fusion and Fission (6)

- Fusion Energy (1)

- Isotope Development and Production (1)

- Isotopes (2)

- Materials (57)

- Neutron Science (12)

- Nuclear Science and Technology (4)

- Supercomputing (12)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (6)

- (-) Energy Storage (6)

- Advanced Reactors (1)

- Artificial Intelligence (12)

- Big Data (6)

- Bioenergy (3)

- Biology (5)

- Biomedical (4)

- Biotechnology (1)

- Buildings (1)

- Chemical Sciences (6)

- Climate Change (5)

- Composites (1)

- Computer Science (25)

- Coronavirus (5)

- Cybersecurity (19)

- Decarbonization (2)

- Environment (6)

- Exascale Computing (1)

- Frontier (1)

- Fusion (1)

- Grid (6)

- High-Performance Computing (4)

- Isotopes (1)

- Machine Learning (12)

- Materials (12)

- Materials Science (18)

- Microscopy (4)

- Nanotechnology (8)

- National Security (35)

- Neutron Science (9)

- Nuclear Energy (5)

- Partnerships (4)

- Physics (1)

- Polymers (6)

- Quantum Computing (1)

- Quantum Science (4)

- Security (12)

- Simulation (1)

- Space Exploration (1)

- Summit (3)

- Sustainable Energy (7)

- Transportation (7)

Media Contacts

Craig Blue, Defense Manufacturing Program Director at the Department of Energy’s Oak Ridge National Laboratory, was recently elected to a two-year term on the Institute for Advanced Composites Manufacturing Innovation Consortium Council, a body of professionals from academia, state governments, and national laboratories that provides strategic direction and oversight to IACMI.

ORNL scientists will present new technologies available for licensing during the annual Technology Innovation Showcase. The event is 9 a.m. to 3 p.m. Thursday, June 16, at the Manufacturing Demonstration Facility at ORNL’s Hardin Valley campus.

How an Alvin M. Weinberg Fellow is increasing security for critical infrastructure components

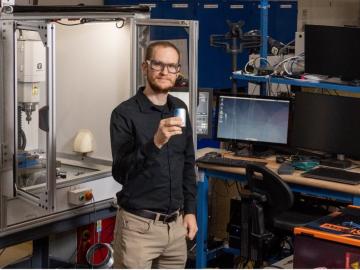

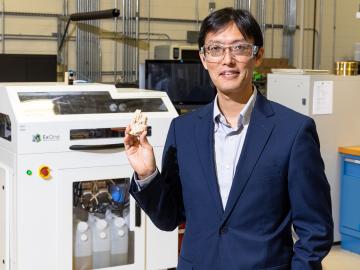

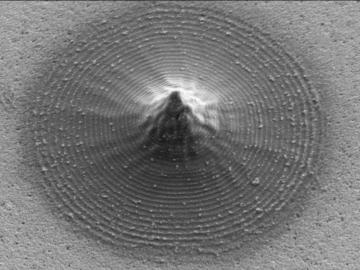

Researchers at ORNL designed a novel polymer to bind and strengthen silica sand for binder jet additive manufacturing, a 3D-printing method used by industries for prototyping and part production.

Through a consortium of Department of Energy national laboratories, ORNL scientists are applying their expertise to provide solutions that enable the commercialization of emission-free hydrogen fuel cell technology for heavy-duty

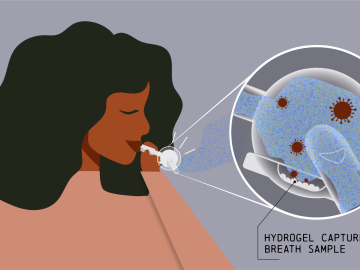

Collaborators at Oak Ridge National Laboratory and the University of Tennessee Health Science Center are developing a breath-sampling whistle that could make COVID-19 screening easy to do at home.

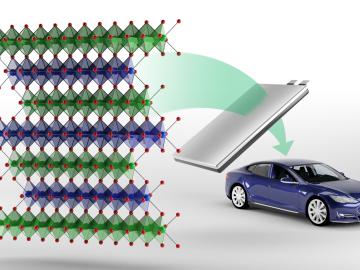

Oak Ridge National Laboratory researchers have developed a new family of cathodes with the potential to replace the costly cobalt-based cathodes typically found in today’s lithium-ion batteries that power electric vehicles and consumer electronics.

Scientists at Oak Ridge National Laboratory and the University of Tennessee designed and demonstrated a method to make carbon-based materials that can be used as electrodes compatible with a specific semiconductor circuitry.

Soteria Battery Innovation Group has exclusively licensed and optioned a technology developed by Oak Ridge National Laboratory designed to eliminate thermal runaway in lithium ion batteries due to mechanical damage.

Four research teams from the Department of Energy’s Oak Ridge National Laboratory and their technologies have received 2020 R&D 100 Awards.