Filter News

Area of Research

- (-) Building Technologies (12)

- (-) Materials for Computing (36)

- (-) Transportation Systems (11)

- Advanced Manufacturing (34)

- Biological Systems (18)

- Biology and Environment (177)

- Biology and Soft Matter (5)

- Chemical and Engineering Materials (4)

- Chemistry and Physics at Interfaces (11)

- Clean Energy (522)

- Climate and Environmental Systems (14)

- Computational Biology (6)

- Computational Chemistry (5)

- Computational Engineering (5)

- Computer Science (19)

- Data (1)

- Earth Sciences (1)

- Electricity and Smart Grid (3)

- Energy Frontier Research Centers (14)

- Energy Sciences (5)

- Fossil Energy (3)

- Fuel Cycle Science and Technology (3)

- Functional Materials for Energy (16)

- Fusion and Fission (54)

- Fusion Energy (19)

- Geographic Information Science and Technology (3)

- Isotope Development and Production (3)

- Isotopes (35)

- Materials (433)

- Materials Characterization (2)

- Materials Synthesis from Atoms to Systems (13)

- Materials Under Extremes (12)

- Mathematics (1)

- National Security (80)

- Neutron Data Analysis and Visualization (4)

- Neutron Science (190)

- Nuclear Science and Technology (74)

- Nuclear Systems Modeling, Simulation and Validation (3)

- Nuclear Systems Technology (1)

- Quantum Condensed Matter (4)

- Quantum information Science (9)

- Reactor Technology (1)

- Renewable Energy (4)

- Sensors and Controls (5)

- Supercomputing (311)

News Topics

- 3-D Printing/Advanced Manufacturing (5)

- Bioenergy (1)

- Biology (1)

- Biomedical (2)

- Buildings (3)

- Chemical Sciences (4)

- Climate Change (1)

- Composites (1)

- Computer Science (8)

- Coronavirus (3)

- Decarbonization (2)

- Energy Storage (4)

- Environment (1)

- Isotopes (1)

- Materials (10)

- Materials Science (16)

- Microscopy (4)

- Nanotechnology (7)

- National Security (1)

- Neutron Science (5)

- Polymers (6)

- Quantum Computing (1)

- Quantum Science (3)

- Security (1)

- Simulation (1)

- Space Exploration (1)

- Summit (1)

- Sustainable Energy (7)

- Transportation (7)

Media Contacts

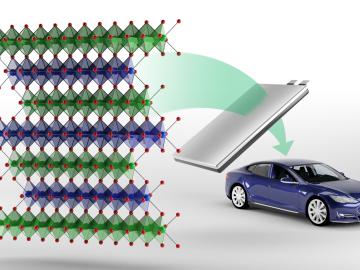

Oak Ridge National Laboratory researchers have developed a new family of cathodes with the potential to replace the costly cobalt-based cathodes typically found in today’s lithium-ion batteries that power electric vehicles and consumer electronics.

Scientists at Oak Ridge National Laboratory and the University of Tennessee designed and demonstrated a method to make carbon-based materials that can be used as electrodes compatible with a specific semiconductor circuitry.

Soteria Battery Innovation Group has exclusively licensed and optioned a technology developed by Oak Ridge National Laboratory designed to eliminate thermal runaway in lithium ion batteries due to mechanical damage.

Four research teams from the Department of Energy’s Oak Ridge National Laboratory and their technologies have received 2020 R&D 100 Awards.

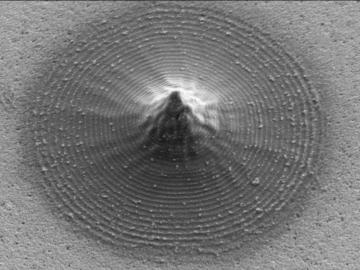

Researchers at Oak Ridge National Laboratory demonstrated that metal foam enhances the evaporation process in thermal conversion systems and enables the development of compact HVAC&R units.

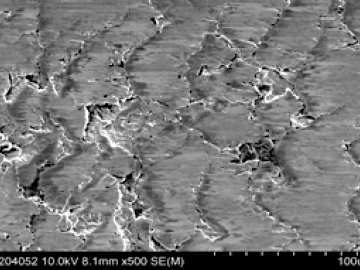

Researchers at Oak Ridge National Laboratory proved that a certain class of ionic liquids, when mixed with commercially available oils, can make gears run more efficiently with less noise and better durability.

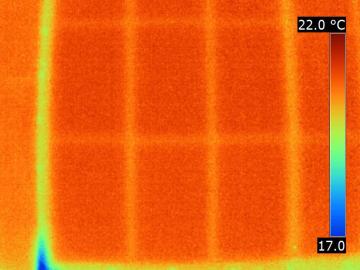

Vacuum insulation technology called modified atmosphere insulation, or MAI, could be a viable solution for improving the energy performance of buildings, based on a study by Oak Ridge National Laboratory and industry partners.

The construction industry may soon benefit from 3D printed molds to make concrete facades, promising lower cost and production time. Researchers at Oak Ridge National Laboratory are evaluating the performance of 3D printed molds used to precast concrete facades in a 42-story buildin...

It’s common knowledge that driving aggressively can dent gas mileage, but it’s difficult to determine exactly how much gas drivers waste. A new study by researchers at the Department of Energy’s Oak Ridge National Laboratory has quantified the impact speeding and slamming on the brakes has on fuel economy and consumption. They found that aggressive behavior behind the wheel can lower gas mileage in light-duty vehicles by about 10 to 40 percent in stop-and-go traffic and roughly 15 to 30 percent at highway speeds. This can equate to losing about $0.25 to $1 per gallon.

A 20-kilowatt wireless charging system demonstrated at the Department of Energy’s Oak Ridge National Laboratory has achieved 90 percent efficiency at three times the rate of the plug-in systems commonly used for electric vehicles today. This ability can help acc...