Filter News

Area of Research

- (-) Clean Energy (136)

- (-) Materials for Computing (17)

- Advanced Manufacturing (6)

- Biology and Environment (123)

- Biology and Soft Matter (1)

- Building Technologies (2)

- Climate and Environmental Systems (5)

- Computational Biology (1)

- Computational Engineering (3)

- Computer Science (15)

- Electricity and Smart Grid (1)

- Energy Sciences (1)

- Functional Materials for Energy (1)

- Fusion and Fission (26)

- Fusion Energy (13)

- Isotopes (2)

- Materials (82)

- Mathematics (1)

- National Security (24)

- Neutron Science (24)

- Nuclear Science and Technology (12)

- Quantum information Science (8)

- Supercomputing (127)

News Topics

- (-) Computer Science (30)

- (-) Environment (54)

- (-) Frontier (2)

- (-) Fusion (1)

- (-) Mathematics (2)

- (-) Microscopy (12)

- (-) Polymers (14)

- (-) Sustainable Energy (70)

- 3-D Printing/Advanced Manufacturing (80)

- Advanced Reactors (6)

- Artificial Intelligence (8)

- Big Data (5)

- Bioenergy (26)

- Biology (11)

- Biomedical (7)

- Biotechnology (4)

- Buildings (36)

- Chemical Sciences (18)

- Clean Water (8)

- Climate Change (21)

- Composites (17)

- Coronavirus (15)

- Critical Materials (9)

- Cybersecurity (8)

- Decarbonization (33)

- Energy Storage (72)

- Exascale Computing (2)

- Fossil Energy (2)

- Grid (40)

- High-Performance Computing (6)

- Hydropower (2)

- Isotopes (2)

- Machine Learning (7)

- Materials (43)

- Materials Science (38)

- Mercury (3)

- Microelectronics (1)

- Molten Salt (1)

- Nanotechnology (14)

- National Security (6)

- Net Zero (3)

- Neutron Science (16)

- Nuclear Energy (7)

- Partnerships (12)

- Physics (1)

- Quantum Computing (1)

- Quantum Science (5)

- Renewable Energy (1)

- Security (7)

- Simulation (4)

- Space Exploration (4)

- Statistics (1)

- Summit (5)

- Transformational Challenge Reactor (3)

- Transportation (67)

Media Contacts

Bruce Warmack has been fascinated by science since his mother finally let him have a chemistry set at the age of nine. He’d been pestering her for one since he was six.

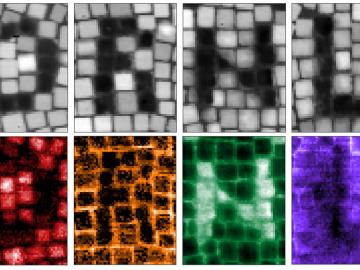

Drilling with the beam of an electron microscope, scientists at ORNL precisely machined tiny electrically conductive cubes that can interact with light and organized them in patterned structures that confine and relay light’s electromagnetic signal.

More than 50 current employees and recent retirees from ORNL received Department of Energy Secretary’s Honor Awards from Secretary Jennifer Granholm in January as part of project teams spanning the national laboratory system. The annual awards recognized 21 teams and three individuals for service and contributions to DOE’s mission and to the benefit of the nation.

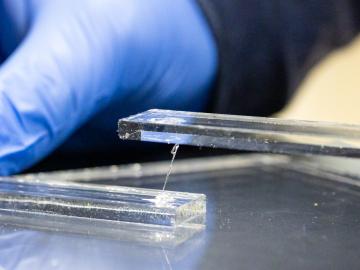

Researchers at ORNL used polymer chemistry to transform a common household plastic into a reusable adhesive with a rare combination of strength and ductility, making it one of the toughest materials ever reported.

Energy and sustainability experts from ORNL, industry, universities and the federal government recently identified key focus areas to meet the challenge of successfully decarbonizing the agriculture sector

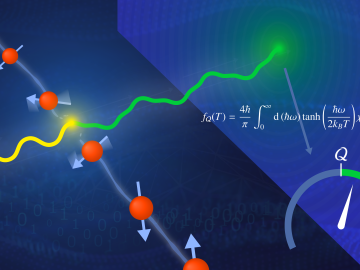

A discovery by Oak Ridge National Laboratory researchers may aid the design of materials that better manage heat.

Ten scientists from the Department of Energy’s Oak Ridge National Laboratory are among the world’s most highly cited researchers, according to a bibliometric analysis conducted by the scientific publication analytics firm Clarivate.

Researchers at ORNL designed a novel polymer to bind and strengthen silica sand for binder jet additive manufacturing, a 3D-printing method used by industries for prototyping and part production.

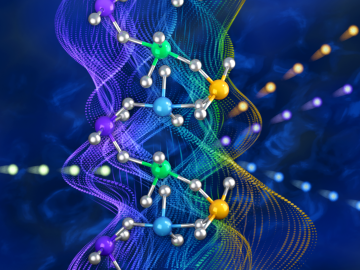

A team led by the U.S. Department of Energy’s Oak Ridge National Laboratory demonstrated the viability of a “quantum entanglement witness” capable of proving the presence of entanglement between magnetic particles, or spins, in a quantum material.

Oak Ridge National Laboratory researchers have developed a novel process to manufacture extreme heat resistant carbon-carbon composites. The performance of these materials will be tested in a U.S. Navy rocket that NASA will launch this fall.