Filter News

Area of Research

- (-) Materials (64)

- (-) Neutron Science (28)

- (-) Nuclear Science and Technology (21)

- Advanced Manufacturing (5)

- Biological Systems (1)

- Biology and Environment (38)

- Clean Energy (48)

- Computational Biology (2)

- Computational Engineering (2)

- Computer Science (7)

- Electricity and Smart Grid (1)

- Energy Frontier Research Centers (1)

- Functional Materials for Energy (1)

- Fusion and Fission (11)

- Fusion Energy (7)

- Isotope Development and Production (1)

- Isotopes (9)

- Materials for Computing (10)

- National Security (18)

- Nuclear Systems Modeling, Simulation and Validation (1)

- Quantum information Science (1)

- Supercomputing (64)

News Topics

- (-) Advanced Reactors (14)

- (-) Artificial Intelligence (12)

- (-) Big Data (3)

- (-) Biomedical (18)

- (-) Composites (9)

- (-) Molten Salt (7)

- (-) Nanotechnology (43)

- (-) Space Exploration (10)

- 3-D Printing/Advanced Manufacturing (30)

- Bioenergy (16)

- Biology (9)

- Biotechnology (1)

- Buildings (5)

- Chemical Sciences (33)

- Clean Water (4)

- Climate Change (5)

- Computer Science (26)

- Coronavirus (12)

- Critical Materials (13)

- Cybersecurity (6)

- Decarbonization (10)

- Energy Storage (38)

- Environment (21)

- Exascale Computing (2)

- Fossil Energy (1)

- Frontier (4)

- Fusion (16)

- Grid (5)

- High-Performance Computing (6)

- Irradiation (1)

- Isotopes (16)

- ITER (1)

- Machine Learning (7)

- Materials (80)

- Materials Science (88)

- Mathematics (1)

- Microscopy (27)

- National Security (4)

- Net Zero (1)

- Neutron Science (108)

- Nuclear Energy (50)

- Partnerships (11)

- Physics (32)

- Polymers (18)

- Quantum Computing (4)

- Quantum Science (15)

- Renewable Energy (1)

- Security (3)

- Simulation (1)

- Summit (6)

- Sustainable Energy (15)

- Transformational Challenge Reactor (5)

- Transportation (19)

Media Contacts

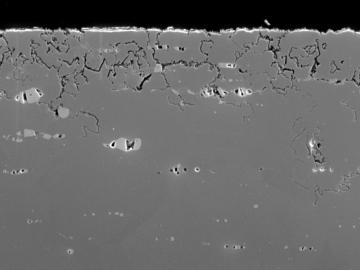

Oak Ridge National Laboratory scientists analyzed more than 50 years of data showing puzzlingly inconsistent trends about corrosion of structural alloys in molten salts and found one factor mattered most—salt purity.

OAK RIDGE, Tenn., Jan. 31, 2019—A new electron microscopy technique that detects the subtle changes in the weight of proteins at the nanoscale—while keeping the sample intact—could open a new pathway for deeper, more comprehensive studies of the basic building blocks of life.

By automating the production of neptunium oxide-aluminum pellets, Oak Ridge National Laboratory scientists have eliminated a key bottleneck when producing plutonium-238 used by NASA to fuel deep space exploration.

The Department of Energy’s Oak Ridge National Laboratory is collaborating with industry on six new projects focused on advancing commercial nuclear energy technologies that offer potential improvements to current nuclear reactors and move new reactor designs closer to deployment.

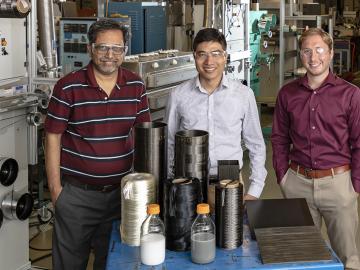

Scientists at the Department of Energy’s Oak Ridge National Laboratory have created a recipe for a renewable 3D printing feedstock that could spur a profitable new use for an intractable biorefinery byproduct: lignin.

![2018-P07635 BL-6 user - Univ of Guelph-6004R_sm[2].jpg 2018-P07635 BL-6 user - Univ of Guelph-6004R_sm[2].jpg](/sites/default/files/styles/list_page_thumbnail/public/2018-P07635%20BL-6%20user%20-%20Univ%20of%20Guelph-6004R_sm%5B2%5D.jpg?itok=DUdZNt_q)

A team of scientists, led by University of Guelph professor John Dutcher, are using neutrons at ORNL’s Spallation Neutron Source to unlock the secrets of natural nanoparticles that could be used to improve medicines.

Scientists from Oak Ridge National Laboratory performed a corrosion test in a neutron radiation field to support the continued development of molten salt reactors.

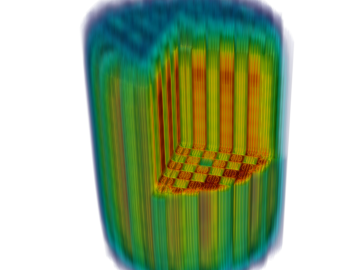

Carbon fiber composites—lightweight and strong—are great structural materials for automobiles, aircraft and other transportation vehicles. They consist of a polymer matrix, such as epoxy, into which reinforcing carbon fibers have been embedded. Because of differences in the mecha...

An Oak Ridge National Laboratory-led team used a scanning transmission electron microscope to selectively position single atoms below a crystal’s surface for the first time.

Experts focused on the future of nuclear technology will gather at Oak Ridge National Laboratory for the fourth annual Molten Salt Reactor Workshop on October 3–4.