Filter News

Area of Research

- (-) Fusion Energy (3)

- (-) Materials (96)

- (-) Neutron Science (33)

- Advanced Manufacturing (22)

- Biology and Environment (26)

- Building Technologies (1)

- Clean Energy (105)

- Computational Biology (1)

- Computational Engineering (1)

- Computer Science (3)

- Electricity and Smart Grid (1)

- Functional Materials for Energy (1)

- Fusion and Fission (7)

- Isotope Development and Production (1)

- Isotopes (2)

- Materials Characterization (1)

- Materials for Computing (17)

- Materials Under Extremes (1)

- National Security (24)

- Nuclear Science and Technology (7)

- Quantum information Science (2)

- Supercomputing (67)

- Transportation Systems (1)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (27)

- (-) Cybersecurity (5)

- (-) Materials Science (87)

- (-) Summit (7)

- Advanced Reactors (11)

- Artificial Intelligence (12)

- Big Data (3)

- Bioenergy (15)

- Biology (9)

- Biomedical (17)

- Biotechnology (1)

- Buildings (5)

- Chemical Sciences (33)

- Clean Water (4)

- Climate Change (5)

- Composites (9)

- Computer Science (26)

- Coronavirus (11)

- Critical Materials (13)

- Decarbonization (9)

- Energy Storage (38)

- Environment (21)

- Exascale Computing (2)

- Fossil Energy (1)

- Frontier (5)

- Fusion (17)

- Grid (5)

- High-Performance Computing (6)

- Irradiation (1)

- Isotopes (13)

- ITER (1)

- Machine Learning (7)

- Materials (80)

- Mathematics (1)

- Microscopy (27)

- Molten Salt (3)

- Nanotechnology (43)

- National Security (4)

- Net Zero (1)

- Neutron Science (106)

- Nuclear Energy (25)

- Partnerships (11)

- Physics (31)

- Polymers (18)

- Quantum Computing (4)

- Quantum Science (15)

- Renewable Energy (1)

- Security (3)

- Simulation (1)

- Space Exploration (5)

- Sustainable Energy (15)

- Transformational Challenge Reactor (3)

- Transportation (19)

Media Contacts

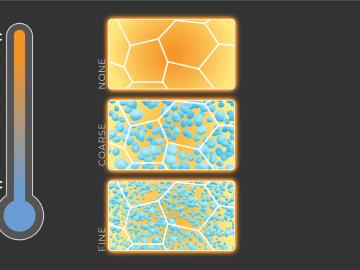

Scientists at ORNL and the University of Tennessee, Knoxville, have found a way to simultaneously increase the strength and ductility of an alloy by introducing tiny precipitates into its matrix and tuning their size and spacing.

The Department of Energy’s Office of Science has selected five Oak Ridge National Laboratory scientists for Early Career Research Program awards.

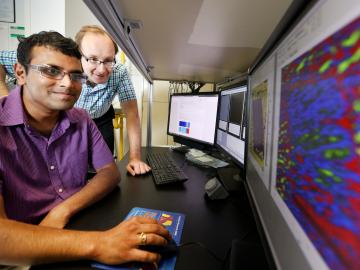

At the Department of Energy’s Oak Ridge National Laboratory, scientists use artificial intelligence, or AI, to accelerate the discovery and development of materials for energy and information technologies.

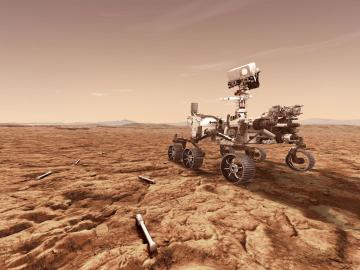

On Feb. 18, the world will be watching as NASA’s Perseverance rover makes its final descent into Jezero Crater on the surface of Mars. Mars 2020 is the first NASA mission that uses plutonium-238 produced at the Department of Energy’s Oak Ridge National Laboratory.

The ExOne Company, the global leader in industrial sand and metal 3D printers using binder jetting technology, announced it has reached a commercial license agreement with Oak Ridge National Laboratory to 3D print parts in aluminum-infiltrated boron carbide.

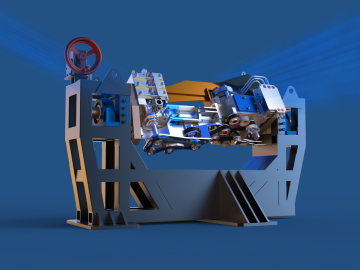

In the quest for advanced vehicles with higher energy efficiency and ultra-low emissions, ORNL researchers are accelerating a research engine that gives scientists and engineers an unprecedented view inside the atomic-level workings of combustion engines in real time.

Six ORNL scientists have been elected as fellows to the American Association for the Advancement of Science, or AAAS.

Seven ORNL scientists have been named among the 2020 Highly Cited Researchers list, according to Clarivate, a data analytics firm that specializes in scientific and academic research.

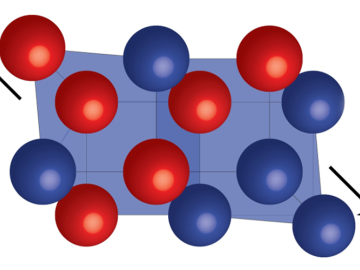

Pauling’s Rules is the standard model used to describe atomic arrangements in ordered materials. Neutron scattering experiments at Oak Ridge National Laboratory confirmed this approach can also be used to describe highly disordered materials.

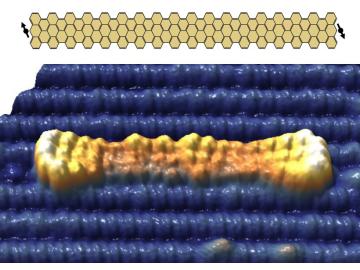

An international multi-institution team of scientists has synthesized graphene nanoribbons – ultrathin strips of carbon atoms – on a titanium dioxide surface using an atomically precise method that removes a barrier for custom-designed carbon