Filter News

Area of Research

- (-) Fusion Energy (10)

- (-) Materials (80)

- Advanced Manufacturing (4)

- Biology and Environment (16)

- Clean Energy (94)

- Computational Biology (1)

- Computational Engineering (1)

- Computer Science (9)

- Electricity and Smart Grid (1)

- Energy Sciences (1)

- Fuel Cycle Science and Technology (1)

- Functional Materials for Energy (2)

- Fusion and Fission (33)

- Isotope Development and Production (1)

- Isotopes (26)

- Materials for Computing (5)

- National Security (33)

- Neutron Science (16)

- Nuclear Science and Technology (38)

- Nuclear Systems Modeling, Simulation and Validation (1)

- Quantum information Science (2)

- Supercomputing (55)

News Topics

- (-) Artificial Intelligence (9)

- (-) Critical Materials (13)

- (-) Cybersecurity (4)

- (-) Energy Storage (34)

- (-) Isotopes (13)

- (-) Nuclear Energy (23)

- (-) Transformational Challenge Reactor (3)

- 3-D Printing/Advanced Manufacturing (23)

- Advanced Reactors (10)

- Big Data (2)

- Bioenergy (11)

- Biology (4)

- Biomedical (7)

- Buildings (5)

- Chemical Sciences (32)

- Clean Water (3)

- Climate Change (5)

- Composites (9)

- Computer Science (19)

- Coronavirus (4)

- Decarbonization (7)

- Environment (15)

- Exascale Computing (2)

- Frontier (4)

- Fusion (16)

- Grid (5)

- High-Performance Computing (4)

- Irradiation (1)

- ITER (1)

- Machine Learning (5)

- Materials (73)

- Materials Science (78)

- Mathematics (1)

- Microscopy (27)

- Molten Salt (3)

- Nanotechnology (39)

- National Security (3)

- Net Zero (1)

- Neutron Science (33)

- Partnerships (11)

- Physics (29)

- Polymers (17)

- Quantum Computing (3)

- Quantum Science (11)

- Renewable Energy (1)

- Security (2)

- Simulation (1)

- Space Exploration (2)

- Summit (3)

- Sustainable Energy (14)

- Transportation (14)

Media Contacts

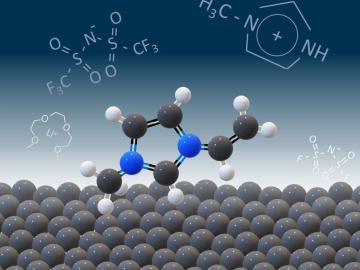

Real-time measurements captured by researchers at ORNL provide missing insight into chemical separations to recover cobalt, a critical raw material used to make batteries and magnets for modern technologies.

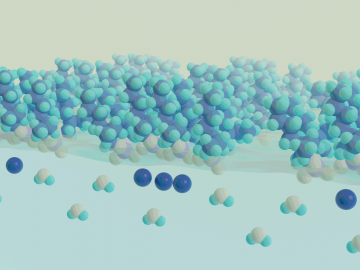

Scientists seeking ways to improve a battery’s ability to hold a charge longer, using advanced materials that are safe, stable and efficient, have determined that the materials themselves are only part of the solution.

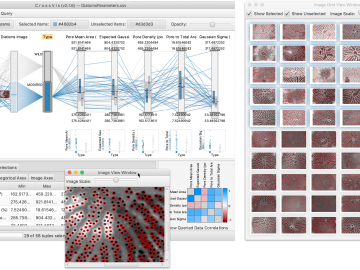

From materials science and earth system modeling to quantum information science and cybersecurity, experts in many fields run simulations and conduct experiments to collect the abundance of data necessary for scientific progress.

Oak Ridge National Laboratory scientists seeking the source of charge loss in lithium-ion batteries demonstrated that coupling a thin-film cathode with a solid electrolyte is a rapid way to determine the root cause.

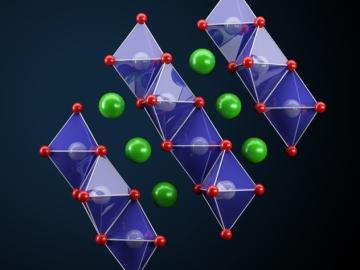

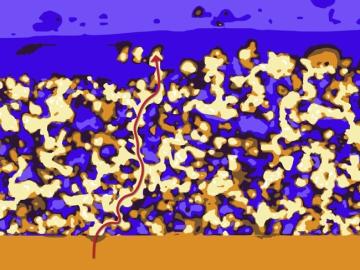

In the search to create materials that can withstand extreme radiation, Yanwen Zhang, a researcher at the Department of Energy’s Oak Ridge National Laboratory, says that materials scientists must think outside the box.

Temperatures hotter than the center of the sun. Magnetic fields hundreds of thousands of times stronger than the earth’s. Neutrons energetic enough to change the structure of a material entirely.

Scientists at the Department of Energy Manufacturing Demonstration Facility at ORNL have their eyes on the prize: the Transformational Challenge Reactor, or TCR, a microreactor built using 3D printing and other new approaches that will be up and running by 2023.

Oak Ridge National Laboratory researchers have developed a thin film, highly conductive solid-state electrolyte made of a polymer and ceramic-based composite for lithium metal batteries.

In the race to identify solutions to the COVID-19 pandemic, researchers at the Department of Energy’s Oak Ridge National Laboratory are joining the fight by applying expertise in computational science, advanced manufacturing, data science and neutron science.

Energy storage startup SPARKZ Inc. has exclusively licensed five battery technologies from the Department of Energy’s Oak Ridge National Laboratory designed to eliminate cobalt metal in lithium-ion batteries. The advancement is aimed at accelerating the production of electric vehicles and energy storage solutions for the power grid.