Filter News

Area of Research

- (-) Advanced Manufacturing (7)

- (-) Fusion Energy (11)

- (-) Materials (75)

- Biology and Environment (123)

- Biology and Soft Matter (1)

- Building Technologies (2)

- Clean Energy (144)

- Climate and Environmental Systems (5)

- Computational Biology (2)

- Computational Engineering (3)

- Computer Science (15)

- Electricity and Smart Grid (1)

- Energy Sciences (1)

- Fuel Cycle Science and Technology (1)

- Functional Materials for Energy (1)

- Fusion and Fission (29)

- Isotope Development and Production (1)

- Isotopes (5)

- Materials for Computing (15)

- Mathematics (1)

- National Security (35)

- Neutron Science (29)

- Nuclear Science and Technology (39)

- Nuclear Systems Modeling, Simulation and Validation (1)

- Quantum information Science (7)

- Sensors and Controls (1)

- Supercomputing (141)

News Topics

- (-) Clean Water (3)

- (-) Computer Science (19)

- (-) Environment (15)

- (-) High-Performance Computing (4)

- (-) Nuclear Energy (24)

- (-) Polymers (17)

- (-) Security (2)

- (-) Summit (3)

- (-) Sustainable Energy (17)

- 3-D Printing/Advanced Manufacturing (42)

- Advanced Reactors (10)

- Artificial Intelligence (10)

- Big Data (2)

- Bioenergy (11)

- Biology (4)

- Biomedical (7)

- Buildings (5)

- Chemical Sciences (32)

- Climate Change (5)

- Composites (12)

- Coronavirus (4)

- Critical Materials (13)

- Cybersecurity (4)

- Decarbonization (7)

- Energy Storage (34)

- Exascale Computing (2)

- Frontier (4)

- Fusion (16)

- Grid (5)

- Irradiation (1)

- Isotopes (13)

- ITER (1)

- Machine Learning (6)

- Materials (79)

- Materials Science (81)

- Mathematics (1)

- Microscopy (27)

- Molten Salt (3)

- Nanotechnology (39)

- National Security (3)

- Net Zero (1)

- Neutron Science (35)

- Partnerships (11)

- Physics (29)

- Quantum Computing (3)

- Quantum Science (11)

- Renewable Energy (1)

- Simulation (1)

- Space Exploration (3)

- Transformational Challenge Reactor (4)

- Transportation (14)

Media Contacts

Oak Ridge National Laboratory researchers have developed a novel process to manufacture extreme heat resistant carbon-carbon composites. The performance of these materials will be tested in a U.S. Navy rocket that NASA will launch this fall.

A research team at Oak Ridge National Laboratory have 3D printed a thermal protection shield, or TPS, for a capsule that will launch with the Cygnus cargo spacecraft as part of the supply mission to the International Space Station.

Oak Ridge National Laboratory expertise in fission and fusion has come together to form a new collaboration, the Fusion Energy Reactor Models Integrator, or FERMI

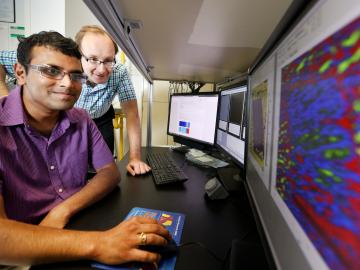

At the Department of Energy’s Oak Ridge National Laboratory, scientists use artificial intelligence, or AI, to accelerate the discovery and development of materials for energy and information technologies.

Six scientists at the Department of Energy’s Oak Ridge National Laboratory were named Battelle Distinguished Inventors, in recognition of obtaining 14 or more patents during their careers at the lab.

Six ORNL scientists have been elected as fellows to the American Association for the Advancement of Science, or AAAS.

Seven ORNL scientists have been named among the 2020 Highly Cited Researchers list, according to Clarivate, a data analytics firm that specializes in scientific and academic research.

Momentum Technologies Inc., a Dallas, Texas-based materials science company that is focused on extracting critical metals from electronic waste, has licensed an Oak Ridge National Laboratory process for recovering cobalt and other metals from spent

About 60 years ago, scientists discovered that a certain rare earth metal-hydrogen mixture, yttrium, could be the ideal moderator to go inside small, gas-cooled nuclear reactors.

A developing method to gauge the occurrence of a nuclear reactor anomaly has the potential to save millions of dollars.