Filter News

Area of Research

- (-) Materials (37)

- (-) National Security (8)

- Advanced Manufacturing (2)

- Biology and Environment (75)

- Clean Energy (22)

- Climate and Environmental Systems (1)

- Computational Biology (2)

- Fusion and Fission (1)

- Materials for Computing (6)

- Neutron Science (100)

- Nuclear Science and Technology (5)

- Supercomputing (23)

News Topics

- (-) Biology (8)

- (-) Neutron Science (35)

- 3-D Printing/Advanced Manufacturing (25)

- Advanced Reactors (6)

- Artificial Intelligence (21)

- Big Data (7)

- Bioenergy (14)

- Biomedical (8)

- Biotechnology (1)

- Buildings (6)

- Chemical Sciences (32)

- Clean Water (3)

- Climate Change (9)

- Composites (9)

- Computer Science (33)

- Coronavirus (6)

- Critical Materials (13)

- Cybersecurity (21)

- Decarbonization (9)

- Energy Storage (35)

- Environment (20)

- Exascale Computing (2)

- Frontier (3)

- Fusion (8)

- Grid (11)

- High-Performance Computing (8)

- Irradiation (1)

- Isotopes (13)

- ITER (1)

- Machine Learning (16)

- Materials (74)

- Materials Science (78)

- Mathematics (1)

- Microscopy (27)

- Molten Salt (3)

- Nanotechnology (39)

- National Security (34)

- Net Zero (1)

- Nuclear Energy (22)

- Partnerships (14)

- Physics (29)

- Polymers (17)

- Quantum Computing (3)

- Quantum Science (12)

- Renewable Energy (1)

- Security (11)

- Simulation (2)

- Space Exploration (2)

- Summit (4)

- Sustainable Energy (16)

- Transformational Challenge Reactor (3)

- Transportation (16)

Media Contacts

Jack Orebaugh, a forensic anthropology major at the University of Tennessee, Knoxville, has a big heart for families with missing loved ones. When someone disappears in an area of dense vegetation, search and recovery efforts can be difficult, especially when a missing person’s last location is unknown. Recognizing the agony of not knowing what happened to a family or friend, Orebaugh decided to use his internship at the Department of Energy’s Oak Ridge National Laboratory to find better ways to search for lost and deceased people using cameras and drones.

Guided by machine learning, chemists at ORNL designed a record-setting carbonaceous supercapacitor material that stores four times more energy than the best commercial material.

In response to a renewed international interest in molten salt reactors, researchers from the Department of Energy’s Oak Ridge National Laboratory have developed a novel technique to visualize molten salt intrusion in graphite.

Using neutrons to see the additive manufacturing process at the atomic level, scientists have shown that they can measure strain in a material as it evolves and track how atoms move in response to stress.

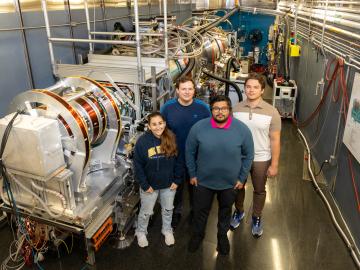

In 2023, the National School on X-ray and Neutron Scattering, or NXS, marked its 25th year during its annual program, held August 6–18 at the Department of Energy’s Oak Ridge and Argonne National Laboratories.

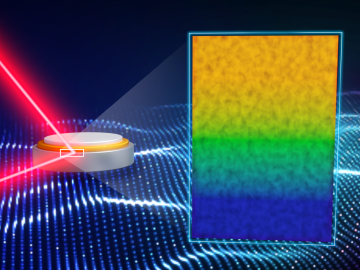

Researchers at the Department of Energy’s Oak Ridge National Laboratory were the first to use neutron reflectometry to peer inside a working solid-state battery and monitor its electrochemistry.

Few things carry the same aura of mystery as dark matter. The name itself radiates secrecy, suggesting something hidden in the shadows of the Universe.

A scientific instrument at ORNL could help create a noninvasive cancer treatment derived from a common tropical plant.

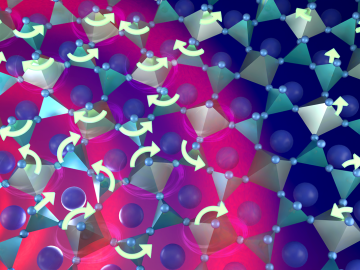

Warming a crystal of the mineral fresnoite, ORNL scientists discovered that excitations called phasons carried heat three times farther and faster than phonons, the excitations that usually carry heat through a material.

The U.S. Departments of Energy and Defense teamed up to create a series of weld filler materials that could dramatically improve high-strength steel repair in vehicles, bridges and pipelines.