Filter News

Area of Research

- (-) Clean Energy (84)

- (-) Neutron Science (102)

- Advanced Manufacturing (6)

- Biological Systems (2)

- Biology and Environment (98)

- Biology and Soft Matter (1)

- Climate and Environmental Systems (1)

- Computational Biology (2)

- Electricity and Smart Grid (1)

- Functional Materials for Energy (1)

- Fusion and Fission (4)

- Materials (56)

- Materials for Computing (7)

- National Security (10)

- Nuclear Science and Technology (6)

- Quantum information Science (1)

- Supercomputing (29)

- Transportation Systems (1)

News Topics

- (-) Bioenergy (30)

- (-) Biology (16)

- (-) Composites (18)

- (-) Decarbonization (34)

- (-) Neutron Science (100)

- 3-D Printing/Advanced Manufacturing (82)

- Advanced Reactors (6)

- Artificial Intelligence (14)

- Big Data (7)

- Biomedical (17)

- Biotechnology (5)

- Buildings (36)

- Chemical Sciences (16)

- Clean Water (10)

- Climate Change (22)

- Computer Science (35)

- Coronavirus (20)

- Critical Materials (9)

- Cybersecurity (9)

- Energy Storage (75)

- Environment (59)

- Exascale Computing (2)

- Fossil Energy (3)

- Frontier (3)

- Fusion (2)

- Grid (40)

- High-Performance Computing (8)

- Hydropower (2)

- Isotopes (1)

- Machine Learning (10)

- Materials (46)

- Materials Science (48)

- Mathematics (3)

- Mercury (3)

- Microelectronics (1)

- Microscopy (10)

- Molten Salt (1)

- Nanotechnology (17)

- National Security (7)

- Net Zero (3)

- Nuclear Energy (9)

- Partnerships (12)

- Physics (10)

- Polymers (12)

- Quantum Computing (1)

- Quantum Science (8)

- Renewable Energy (1)

- Security (8)

- Simulation (4)

- Space Exploration (6)

- Statistics (1)

- Summit (9)

- Sustainable Energy (69)

- Transformational Challenge Reactor (3)

- Transportation (67)

Media Contacts

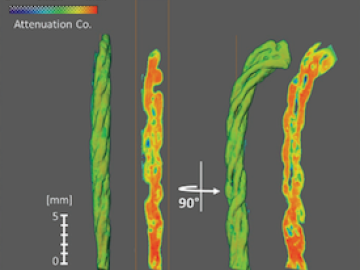

Textile engineering researchers from North Carolina State University used neutrons at Oak Ridge National Laboratory to identify a special wicking mechanism in a type of cotton yarn that allows the fibers to control the flow of liquid across certain strands.

ORNL and the Tennessee Valley Authority, or TVA, are joining forces to advance decarbonization technologies from discovery through deployment through a new memorandum of understanding, or MOU.

Cement trucks entering and exiting the Spallation Neutron Source are a common sight as construction of the VENUS neutron imaging beamline progresses. Slated for completion and commissioning in 2024-2025, VENUS is the twentieth neutron instrument at SNS and will offer many new capabilities.

Three ORNL scientists have been elected fellows of the American Association for the Advancement of Science, or AAAS, the world’s largest general scientific society and publisher of the Science family of journals.

Energy and sustainability experts from ORNL, industry, universities and the federal government recently identified key focus areas to meet the challenge of successfully decarbonizing the agriculture sector

ORNL and Tuskegee University have formed a partnership to develop new biodegradable materials for use in buildings, transportation and biomedical applications.

Ten scientists from the Department of Energy’s Oak Ridge National Laboratory are among the world’s most highly cited researchers, according to a bibliometric analysis conducted by the scientific publication analytics firm Clarivate.

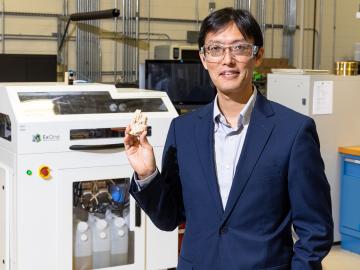

Researchers at ORNL designed a novel polymer to bind and strengthen silica sand for binder jet additive manufacturing, a 3D-printing method used by industries for prototyping and part production.

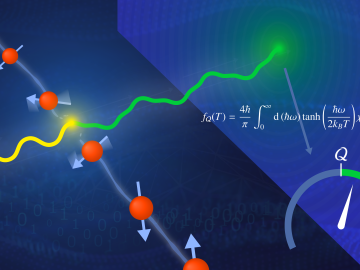

A team led by the U.S. Department of Energy’s Oak Ridge National Laboratory demonstrated the viability of a “quantum entanglement witness” capable of proving the presence of entanglement between magnetic particles, or spins, in a quantum material.