Filter News

Area of Research

- (-) Clean Energy (97)

- (-) Materials (41)

- (-) Neutron Science (25)

- Advanced Manufacturing (22)

- Biological Systems (1)

- Biology and Environment (37)

- Building Technologies (1)

- Computational Biology (2)

- Computational Engineering (2)

- Computer Science (7)

- Electricity and Smart Grid (1)

- Functional Materials for Energy (1)

- Fusion and Fission (7)

- Fusion Energy (1)

- Isotope Development and Production (1)

- Isotopes (9)

- Materials for Computing (5)

- National Security (24)

- Nuclear Science and Technology (15)

- Sensors and Controls (1)

- Supercomputing (63)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (91)

- (-) Artificial Intelligence (16)

- (-) Big Data (8)

- (-) Biomedical (20)

- (-) Fossil Energy (3)

- (-) Molten Salt (3)

- (-) Security (8)

- (-) Space Exploration (8)

- Advanced Reactors (9)

- Bioenergy (33)

- Biology (17)

- Biotechnology (5)

- Buildings (36)

- Chemical Sciences (34)

- Clean Water (11)

- Climate Change (23)

- Composites (19)

- Computer Science (42)

- Coronavirus (21)

- Critical Materials (19)

- Cybersecurity (11)

- Decarbonization (35)

- Energy Storage (89)

- Environment (67)

- Exascale Computing (3)

- Frontier (4)

- Fusion (8)

- Grid (41)

- High-Performance Computing (11)

- Hydropower (2)

- Irradiation (1)

- Isotopes (13)

- ITER (1)

- Machine Learning (12)

- Materials (100)

- Materials Science (99)

- Mathematics (3)

- Mercury (3)

- Microelectronics (1)

- Microscopy (29)

- Nanotechnology (45)

- National Security (7)

- Net Zero (3)

- Neutron Science (107)

- Nuclear Energy (23)

- Partnerships (16)

- Physics (31)

- Polymers (22)

- Quantum Computing (4)

- Quantum Science (16)

- Renewable Energy (1)

- Simulation (4)

- Statistics (1)

- Summit (9)

- Sustainable Energy (71)

- Transformational Challenge Reactor (5)

- Transportation (71)

Media Contacts

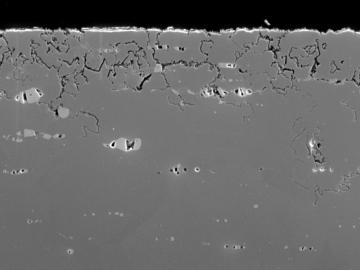

Oak Ridge National Laboratory scientists analyzed more than 50 years of data showing puzzlingly inconsistent trends about corrosion of structural alloys in molten salts and found one factor mattered most—salt purity.

![Coexpression_hi-res_image[1].jpg Coexpression_hi-res_image[1].jpg](/sites/default/files/styles/list_page_thumbnail/public/Coexpression_hi-res_image%5B1%5D_0.jpg?itok=OnLe-krT)

While studying the genes in poplar trees that control callus formation, scientists at Oak Ridge National Laboratory have uncovered genetic networks at the root of tumor formation in several human cancers.

By automating the production of neptunium oxide-aluminum pellets, Oak Ridge National Laboratory scientists have eliminated a key bottleneck when producing plutonium-238 used by NASA to fuel deep space exploration.

Scientists at the Department of Energy’s Oak Ridge National Laboratory have created a recipe for a renewable 3D printing feedstock that could spur a profitable new use for an intractable biorefinery byproduct: lignin.

![2018-P07635 BL-6 user - Univ of Guelph-6004R_sm[2].jpg 2018-P07635 BL-6 user - Univ of Guelph-6004R_sm[2].jpg](/sites/default/files/styles/list_page_thumbnail/public/2018-P07635%20BL-6%20user%20-%20Univ%20of%20Guelph-6004R_sm%5B2%5D.jpg?itok=DUdZNt_q)

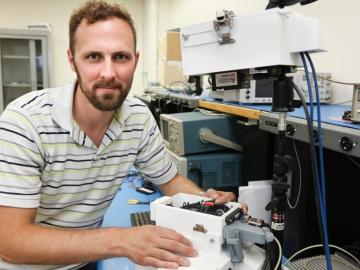

A team of scientists, led by University of Guelph professor John Dutcher, are using neutrons at ORNL’s Spallation Neutron Source to unlock the secrets of natural nanoparticles that could be used to improve medicines.

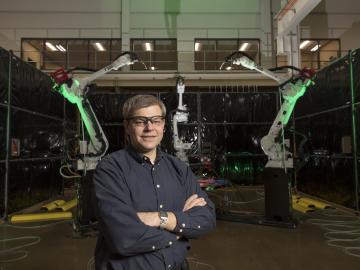

Two leaders in US manufacturing innovation, Thomas Kurfess and Scott Smith, are joining the Department of Energy’s Oak Ridge National Laboratory to support its pioneering research in advanced manufacturing.

The construction industry may soon benefit from 3D printed molds to make concrete facades, promising lower cost and production time. Researchers at Oak Ridge National Laboratory are evaluating the performance of 3D printed molds used to precast concrete facades in a 42-story buildin...

Oak Ridge National Laboratory scientists have improved a mixture of materials used to 3D print permanent magnets with increased density, which could yield longer lasting, better performing magnets for electric motors, sensors and vehicle applications. Building on previous research, ...

As leader of the RF, Communications, and Cyber-Physical Security Group at Oak Ridge National Laboratory, Kerekes heads an accelerated lab-directed research program to build virtual models of critical infrastructure systems like the power grid that can be used to develop ways to detect and repel cyber-intrusion and to make the network resilient when disruption occurs.