Filter News

Area of Research

- (-) Clean Energy (168)

- (-) Materials (78)

- (-) Neutron Science (30)

- Advanced Manufacturing (22)

- Biology and Environment (45)

- Building Technologies (2)

- Climate and Environmental Systems (1)

- Computational Biology (1)

- Computational Engineering (3)

- Computer Science (16)

- Electricity and Smart Grid (1)

- Fuel Cycle Science and Technology (1)

- Functional Materials for Energy (1)

- Fusion and Fission (30)

- Fusion Energy (11)

- Isotope Development and Production (1)

- Isotopes (26)

- Materials for Computing (16)

- Mathematics (1)

- National Security (40)

- Nuclear Science and Technology (39)

- Nuclear Systems Modeling, Simulation and Validation (1)

- Quantum information Science (6)

- Renewable Energy (1)

- Supercomputing (138)

- Transportation Systems (2)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (91)

- (-) Artificial Intelligence (16)

- (-) Computer Science (42)

- (-) Cybersecurity (11)

- (-) Exascale Computing (3)

- (-) Hydropower (2)

- (-) Isotopes (13)

- (-) Nuclear Energy (23)

- (-) Quantum Computing (4)

- (-) Transportation (71)

- Advanced Reactors (9)

- Big Data (8)

- Bioenergy (33)

- Biology (17)

- Biomedical (20)

- Biotechnology (5)

- Buildings (36)

- Chemical Sciences (34)

- Clean Water (11)

- Climate Change (23)

- Composites (19)

- Coronavirus (21)

- Critical Materials (19)

- Decarbonization (35)

- Energy Storage (89)

- Environment (67)

- Fossil Energy (3)

- Frontier (4)

- Fusion (8)

- Grid (41)

- High-Performance Computing (11)

- Irradiation (1)

- ITER (1)

- Machine Learning (12)

- Materials (100)

- Materials Science (99)

- Mathematics (3)

- Mercury (3)

- Microelectronics (1)

- Microscopy (29)

- Molten Salt (3)

- Nanotechnology (45)

- National Security (7)

- Net Zero (3)

- Neutron Science (107)

- Partnerships (16)

- Physics (31)

- Polymers (22)

- Quantum Science (16)

- Renewable Energy (1)

- Security (8)

- Simulation (4)

- Space Exploration (8)

- Statistics (1)

- Summit (9)

- Sustainable Energy (71)

- Transformational Challenge Reactor (5)

Media Contacts

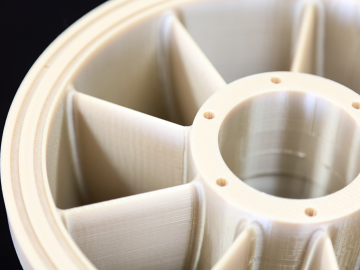

A new report published by ORNL assessed how advanced manufacturing and materials, such as 3D printing and novel component coatings, could offer solutions to modernize the existing fleet and design new approaches to hydropower.

When aging vehicle batteries lack the juice to power your car anymore, they may still hold energy. Yet it’s tough to find new uses for lithium-ion batteries with different makers, ages and sizes. A solution is urgently needed because battery recycling options are scarce.

Three scientists from the Department of Energy’s Oak Ridge National Laboratory have been elected fellows of the American Association for the Advancement of Science, or AAAS.

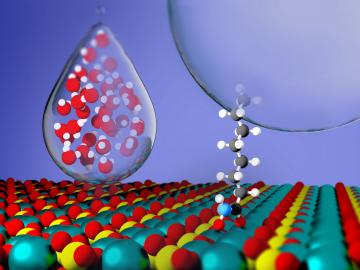

Critical Materials Institute researchers at Oak Ridge National Laboratory and Arizona State University studied the mineral monazite, an important source of rare-earth elements, to enhance methods of recovering critical materials for energy, defense and manufacturing applications.

Merlin Theodore is one of eight new board members announced by President Biden; she will join the 25-member board for a six-year term.

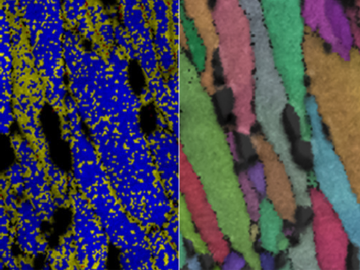

ORNL researchers have identified a mechanism in a 3D-printed alloy – termed “load shuffling” — that could enable the design of better-performing lightweight materials for vehicles.

Seven scientists at the Department of Energy’s Oak Ridge National Laboratory have been named Battelle Distinguished Inventors, in recognition of their obtaining 14 or more patents during their careers at the lab.

The U.S. Departments of Energy and Defense teamed up to create a series of weld filler materials that could dramatically improve high-strength steel repair in vehicles, bridges and pipelines.

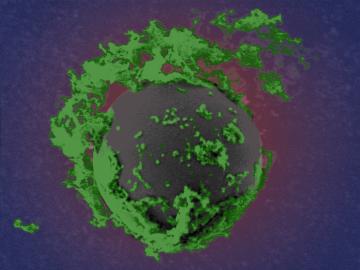

The presence of minerals called ash in plants makes little difference to the fitness of new naturally derived compound materials designed for additive manufacturing, an Oak Ridge National Laboratory-led team found.

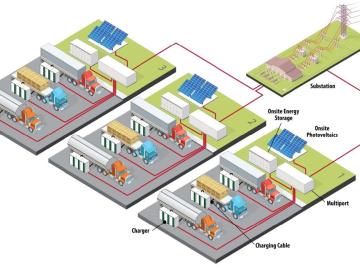

Researchers at Oak Ridge National Laboratory have designed architecture, software and control strategies for a futuristic EV truck stop that can draw megawatts of power and reduce carbon emissions.