Filter News

Area of Research

- (-) Clean Energy (187)

- (-) Materials (66)

- (-) National Security (28)

- Advanced Manufacturing (22)

- Biology and Environment (26)

- Building Technologies (4)

- Computational Biology (1)

- Computational Engineering (1)

- Computer Science (3)

- Electricity and Smart Grid (1)

- Fuel Cycle Science and Technology (1)

- Functional Materials for Energy (1)

- Fusion and Fission (29)

- Fusion Energy (11)

- Isotope Development and Production (1)

- Isotopes (26)

- Materials for Computing (10)

- Neutron Science (19)

- Nuclear Science and Technology (38)

- Nuclear Systems Modeling, Simulation and Validation (1)

- Quantum information Science (2)

- Supercomputing (64)

- Transportation Systems (2)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (91)

- (-) Buildings (38)

- (-) Composites (19)

- (-) Cybersecurity (26)

- (-) Isotopes (13)

- (-) Nuclear Energy (26)

- (-) Summit (8)

- (-) Transportation (72)

- Advanced Reactors (10)

- Artificial Intelligence (24)

- Big Data (12)

- Bioenergy (32)

- Biology (15)

- Biomedical (11)

- Biotechnology (5)

- Chemical Sciences (33)

- Clean Water (10)

- Climate Change (26)

- Computer Science (50)

- Coronavirus (16)

- Critical Materials (19)

- Decarbonization (35)

- Energy Storage (86)

- Environment (69)

- Exascale Computing (3)

- Fossil Energy (2)

- Frontier (3)

- Fusion (8)

- Grid (45)

- High-Performance Computing (13)

- Hydropower (2)

- Irradiation (1)

- ITER (1)

- Machine Learning (20)

- Materials (95)

- Materials Science (90)

- Mathematics (3)

- Mercury (3)

- Microelectronics (1)

- Microscopy (29)

- Molten Salt (3)

- Nanotechnology (41)

- National Security (37)

- Net Zero (3)

- Neutron Science (44)

- Partnerships (20)

- Physics (29)

- Polymers (21)

- Quantum Computing (3)

- Quantum Science (13)

- Renewable Energy (1)

- Security (15)

- Simulation (4)

- Space Exploration (5)

- Statistics (1)

- Sustainable Energy (71)

- Transformational Challenge Reactor (5)

Media Contacts

An Oak Ridge National Laboratory-developed advanced manufacturing technology, AMCM, was recently licensed by Orbital Composites and enables the rapid production of composite-based components, which could accelerate the decarbonization of vehicles

ORNL, a bastion of nuclear physics research for the past 80 years, is poised to strengthen its programs and service to the United States over the next decade if national recommendations of the Nuclear Science Advisory Committee, or NSAC, are enacted.

The common sounds in the background of daily life – like a refrigerator’s hum, an air conditioner’s whoosh and a heat pump’s buzz – often go unnoticed. These noises, however, are the heartbeat of a healthy building and integral for comfort and convenience.

Oak Ridge National Laboratory researchers have conducted a comprehensive life cycle, cost and carbon emissions analysis on 3D-printed molds for precast concrete and determined the method is economically beneficial compared to conventional wood molds.

The Department of Energy’s Oak Ridge National Laboratory hosted its Smoky Mountains Computational Science and Engineering Conference for the first time in person since the COVID pandemic broke in 2020. The conference, which celebrated its 20th consecutive year, took place at the Crowne Plaza Hotel in downtown Knoxville, Tenn., in late August.

Carl Dukes’ career as an adept communicator got off to a slow start: He was about 5 years old when he spoke for the first time. “I’ve been making up for lost time ever since,” joked Dukes, a technical professional at the Department of Energy’s Oak Ridge National Laboratory.

Tom Karnowski and Jordan Johnson of ORNL have been named chair and vice chair, respectively, of the East Tennessee section of the Institute of Electrical and Electronics Engineers, or IEEE.

Researchers at the Department of Energy’s Oak Ridge National Laboratory have created a new detection system that allows home energy auditors to see air leaking from a building in real time with the help of a camera.

Subho Mukherjee, an R&D associate in the Vehicle Power Electronics Research group at the Department of Energy’s Oak Ridge National Laboratory, has been elevated to the grade of senior member of the Institute of Electrical and Electronics Engineers.

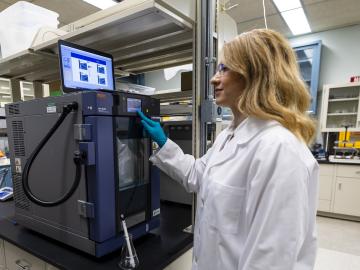

A licensing agreement between the Department of Energy’s Oak Ridge National Laboratory and research partner ZEISS will enable industrial X-ray computed tomography, or CT, to perform rapid evaluations of 3D-printed components using ORNL’s machine