Filter News

Area of Research

- (-) Biology and Environment (34)

- (-) Clean Energy (40)

- Advanced Manufacturing (3)

- Biology and Soft Matter (1)

- Computational Biology (1)

- Computational Engineering (2)

- Computer Science (9)

- Electricity and Smart Grid (1)

- Fuel Cycle Science and Technology (1)

- Functional Materials for Energy (1)

- Fusion and Fission (31)

- Fusion Energy (10)

- Isotope Development and Production (1)

- Isotopes (3)

- Materials (83)

- Materials for Computing (10)

- Mathematics (1)

- National Security (19)

- Neutron Science (19)

- Nuclear Science and Technology (36)

- Nuclear Systems Modeling, Simulation and Validation (1)

- Quantum information Science (9)

- Supercomputing (69)

News Topics

- (-) Artificial Intelligence (15)

- (-) Chemical Sciences (18)

- (-) Clean Water (19)

- (-) Microscopy (15)

- (-) Nuclear Energy (7)

- (-) Quantum Science (2)

- 3-D Printing/Advanced Manufacturing (80)

- Advanced Reactors (6)

- Big Data (14)

- Bioenergy (65)

- Biology (79)

- Biomedical (20)

- Biotechnology (16)

- Buildings (36)

- Climate Change (58)

- Composites (19)

- Computer Science (41)

- Coronavirus (22)

- Critical Materials (9)

- Cybersecurity (9)

- Decarbonization (47)

- Energy Storage (73)

- Environment (136)

- Exascale Computing (6)

- Fossil Energy (2)

- Frontier (5)

- Fusion (2)

- Grid (41)

- High-Performance Computing (23)

- Hydropower (9)

- Isotopes (2)

- Machine Learning (14)

- Materials (39)

- Materials Science (29)

- Mathematics (5)

- Mercury (10)

- Microelectronics (1)

- Molten Salt (1)

- Nanotechnology (11)

- National Security (7)

- Net Zero (5)

- Neutron Science (15)

- Partnerships (12)

- Physics (2)

- Polymers (12)

- Renewable Energy (2)

- Security (6)

- Simulation (17)

- Space Exploration (3)

- Statistics (1)

- Summit (13)

- Sustainable Energy (93)

- Transformational Challenge Reactor (3)

- Transportation (66)

Media Contacts

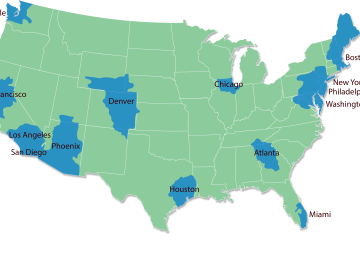

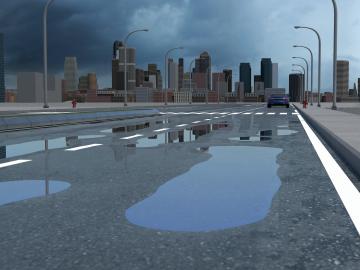

Oak Ridge National Laboratory worked with Colorado State University to simulate how a warming climate may affect U.S. urban hydrological systems.

Moving to landlocked Tennessee isn’t an obvious choice for most scientists with new doctorate degrees in coastal oceanography.

Four first-of-a-kind 3D-printed fuel assembly brackets, produced at the Department of Energy’s Manufacturing Demonstration Facility at Oak Ridge National Laboratory, have been installed and are now under routine operating

The Accelerating Therapeutics for Opportunities in Medicine , or ATOM, consortium today announced the U.S. Department of Energy’s Oak Ridge, Argonne and Brookhaven national laboratories are joining the consortium to further develop ATOM’s artificial intelligence, or AI-driven, drug discovery platform.

Researchers at Oak Ridge National Laboratory have identified a statistical relationship between the growth of cities and the spread of paved surfaces like roads and sidewalks. These impervious surfaces impede the flow of water into the ground, affecting the water cycle and, by extension, the climate.

Algorithms developed at Oak Ridge National Laboratory can greatly enhance X-ray computed tomography images of 3D-printed metal parts, resulting in more accurate, faster scans.

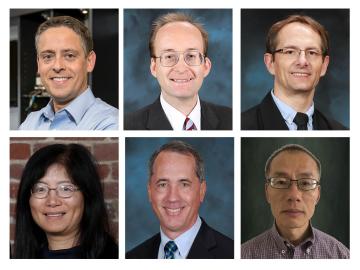

Six scientists at the Department of Energy’s Oak Ridge National Laboratory were named Battelle Distinguished Inventors, in recognition of obtaining 14 or more patents during their careers at the lab.

Seven ORNL scientists have been named among the 2020 Highly Cited Researchers list, according to Clarivate, a data analytics firm that specializes in scientific and academic research.

New capabilities and equipment recently installed at the Department of Energy’s Oak Ridge National Laboratory are bringing a creek right into the lab to advance understanding of mercury pollution and accelerate solutions.

The Transformational Challenge Reactor, or TCR, a microreactor built using 3D printing and other new advanced technologies, could be operational by 2024.