Filter News

Area of Research

- (-) Clean Energy (522)

- (-) Isotopes (35)

- (-) Materials (433)

- Advanced Manufacturing (34)

- Biological Systems (18)

- Biology and Environment (177)

- Biology and Soft Matter (5)

- Building Technologies (12)

- Chemical and Engineering Materials (4)

- Chemistry and Physics at Interfaces (11)

- Climate and Environmental Systems (14)

- Computational Biology (6)

- Computational Chemistry (5)

- Computational Engineering (5)

- Computer Science (19)

- Data (1)

- Earth Sciences (1)

- Electricity and Smart Grid (3)

- Energy Frontier Research Centers (14)

- Energy Sciences (5)

- Fossil Energy (3)

- Fuel Cycle Science and Technology (3)

- Functional Materials for Energy (16)

- Fusion and Fission (54)

- Fusion Energy (17)

- Geographic Information Science and Technology (3)

- Isotope Development and Production (3)

- Materials Characterization (2)

- Materials for Computing (36)

- Materials Synthesis from Atoms to Systems (13)

- Materials Under Extremes (12)

- Mathematics (1)

- National Security (79)

- Neutron Data Analysis and Visualization (4)

- Neutron Science (190)

- Nuclear Science and Technology (74)

- Nuclear Systems Modeling, Simulation and Validation (3)

- Nuclear Systems Technology (1)

- Quantum Condensed Matter (4)

- Quantum information Science (9)

- Reactor Technology (1)

- Renewable Energy (4)

- Sensors and Controls (5)

- Supercomputing (311)

- Transportation Systems (11)

News Type

News Topics

- 3-D Printing/Advanced Manufacturing (89)

- Advanced Reactors (9)

- Artificial Intelligence (13)

- Big Data (7)

- Bioenergy (30)

- Biology (12)

- Biomedical (14)

- Biotechnology (4)

- Buildings (36)

- Chemical Sciences (33)

- Clean Water (10)

- Climate Change (23)

- Composites (19)

- Computer Science (37)

- Coronavirus (14)

- Critical Materials (19)

- Cybersecurity (10)

- Decarbonization (34)

- Energy Storage (86)

- Environment (64)

- Exascale Computing (3)

- Fossil Energy (2)

- Frontier (3)

- Fusion (7)

- Grid (41)

- High-Performance Computing (9)

- Hydropower (2)

- Irradiation (2)

- Isotopes (33)

- ITER (1)

- Machine Learning (10)

- Materials (94)

- Materials Science (91)

- Mathematics (3)

- Mercury (3)

- Microelectronics (1)

- Microscopy (29)

- Molten Salt (3)

- Nanotechnology (41)

- National Security (7)

- Net Zero (3)

- Neutron Science (42)

- Nuclear Energy (25)

- Partnerships (16)

- Physics (29)

- Polymers (21)

- Quantum Computing (3)

- Quantum Science (12)

- Renewable Energy (1)

- Security (8)

- Simulation (4)

- Space Exploration (8)

- Statistics (1)

- Summit (6)

- Sustainable Energy (71)

- Transformational Challenge Reactor (5)

- Transportation (69)

Media Contacts

Since its inception in 2010, the program bolsters national scientific discovery by supporting early career researchers in fields pertaining to the Office of Science.

Dean Pierce of ORNL and a research team led by ORNL’s Alex Plotkowski were honored by DOE’s Vehicle Technologies Office for development of novel high-performance alloys that can withstand extreme environments.

Xiao-Ying Yu, a distinguished scientist at the Department of Energy’s Oak Ridge National Laboratory, has been named a Fellow of AVS: Science and Technology of Materials, Interfaces, and Processing, formerly American Vacuum Society.

Yarom Polsky, director of the Manufacturing Science Division, or MSD, at the Department of Energy’s Oak Ridge National Laboratory, has been elected a Fellow of the American Society of Mechanical Engineers, or ASME.

ORNL nuclear chemist Clarice Phelps has long worked to educate the next generation of STEM scientists. A new endeavor will let her reach students entering college who need extra help mastering the basics they need to pursue careers in science.

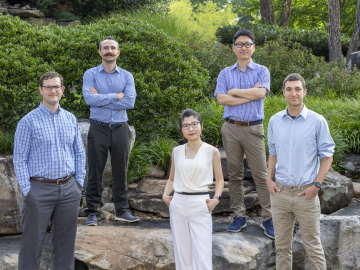

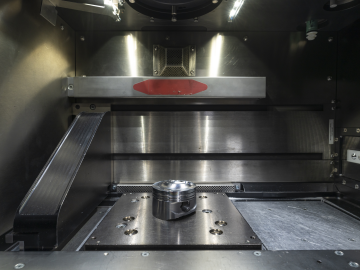

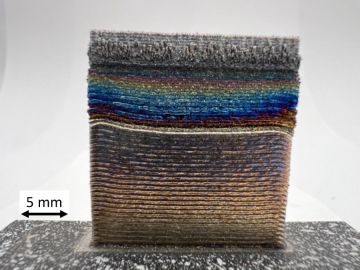

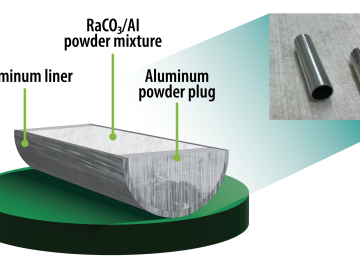

Research into a new, unique technology to fabricate composite metal parts for a wide range of applications operating in extreme environments across the aviation, space and energy industries is showing promise for additive manufacturing.

Early experiments at the Department of Energy’s Oak Ridge National Laboratory have revealed significant benefits to a dry battery manufacturing process. This eliminates the use of solvents and is more affordable, while showing promise for delivering a battery that is durable, less weighed down by inactive elements, and able to maintain a high capacity after use.

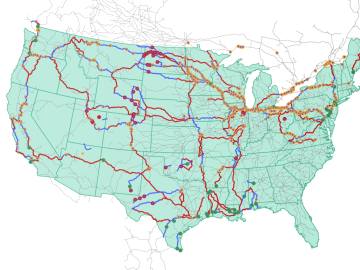

Oak Ridge National Laboratory researchers used images from a photo-sharing website to identify crude oil train routes across the nation to provide data that could help transportation planners better understand regional impacts.

Jacob McCulley of the Department of Energy’s Oak Ridge National Laboratory has been named a senior member of the Institute of Electrical and Electronics Engineers, or IEEE, one of the world’s largest technical professional

Oak Ridge National Laboratory researchers have developed a method to simplify one step of radioisotope production — and it’s faster and safer.