Filter News

Area of Research

- (-) Clean Energy (88)

- (-) Materials (91)

- Advanced Manufacturing (4)

- Biology and Environment (55)

- Biology and Soft Matter (1)

- Climate and Environmental Systems (2)

- Computational Engineering (1)

- Computer Science (5)

- Electricity and Smart Grid (3)

- Energy Frontier Research Centers (1)

- Functional Materials for Energy (1)

- Fusion and Fission (9)

- Fusion Energy (7)

- Isotopes (1)

- Materials for Computing (11)

- Mathematics (1)

- National Security (14)

- Neutron Science (26)

- Nuclear Science and Technology (13)

- Nuclear Systems Modeling, Simulation and Validation (1)

- Quantum information Science (9)

- Sensors and Controls (1)

- Supercomputing (59)

News Topics

- (-) Advanced Reactors (9)

- (-) Climate Change (23)

- (-) Composites (19)

- (-) Grid (41)

- (-) Nanotechnology (41)

- (-) Physics (29)

- (-) Quantum Science (12)

- 3-D Printing/Advanced Manufacturing (89)

- Artificial Intelligence (13)

- Big Data (7)

- Bioenergy (30)

- Biology (12)

- Biomedical (10)

- Biotechnology (4)

- Buildings (36)

- Chemical Sciences (33)

- Clean Water (10)

- Computer Science (36)

- Coronavirus (14)

- Critical Materials (19)

- Cybersecurity (10)

- Decarbonization (34)

- Energy Storage (86)

- Environment (64)

- Exascale Computing (3)

- Fossil Energy (2)

- Frontier (3)

- Fusion (7)

- High-Performance Computing (9)

- Hydropower (2)

- Irradiation (1)

- Isotopes (13)

- ITER (1)

- Machine Learning (10)

- Materials (94)

- Materials Science (90)

- Mathematics (3)

- Mercury (3)

- Microelectronics (1)

- Microscopy (29)

- Molten Salt (3)

- National Security (6)

- Net Zero (3)

- Neutron Science (42)

- Nuclear Energy (22)

- Partnerships (16)

- Polymers (21)

- Quantum Computing (3)

- Renewable Energy (1)

- Security (7)

- Simulation (4)

- Space Exploration (5)

- Statistics (1)

- Summit (6)

- Sustainable Energy (71)

- Transformational Challenge Reactor (5)

- Transportation (69)

Media Contacts

ORNL and The University of Toledo have entered into a memorandum of understanding for collaborative research.

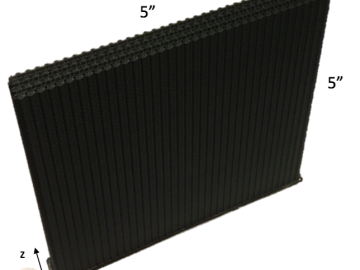

A team including Oak Ridge National Laboratory and University of Tennessee researchers demonstrated a novel 3D printing approach called Z-pinning that can increase the material’s strength and toughness by more than three and a half times compared to conventional additive manufacturing processes.

Isabelle Snyder calls faults as she sees them, whether it’s modeling operations for the nation’s power grid or officiating at the US Open Tennis Championships.

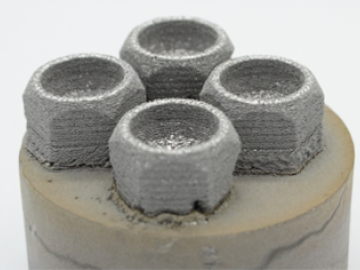

Using additive manufacturing, scientists experimenting with tungsten at Oak Ridge National Laboratory hope to unlock new potential of the high-performance heat-transferring material used to protect components from the plasma inside a fusion reactor. Fusion requires hydrogen isotopes to reach millions of degrees.

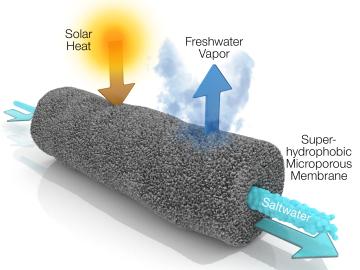

A new method developed at Oak Ridge National Laboratory improves the energy efficiency of a desalination process known as solar-thermal evaporation.

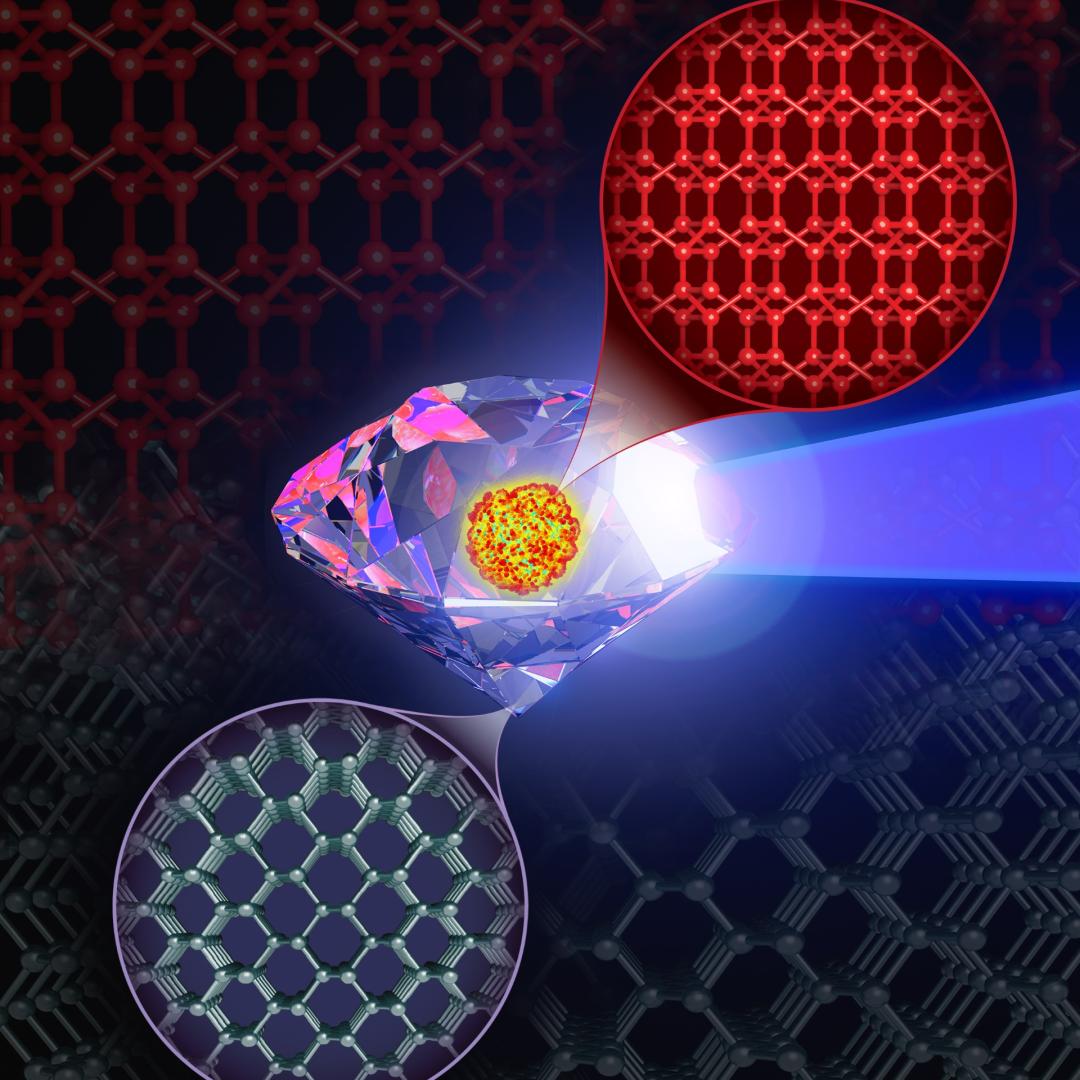

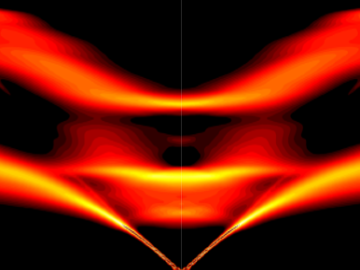

Scientists have discovered a way to alter heat transport in thermoelectric materials, a finding that may ultimately improve energy efficiency as the materials

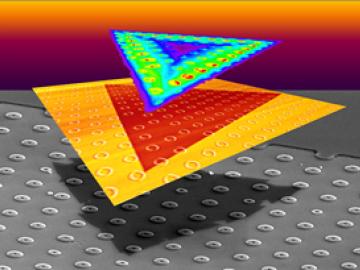

A team led by scientists at the Department of Energy’s Oak Ridge National Laboratory explored how atomically thin two-dimensional (2D) crystals can grow over 3D objects and how the curvature of those objects can stretch and strain the

OAK RIDGE, Tenn., May 7, 2019—Energy Secretary Rick Perry, Congressman Chuck Fleischmann and lab officials today broke ground on a multipurpose research facility that will provide state-of-the-art laboratory space

Scientists at Oak Ridge National Laboratory have developed a low-cost, printed, flexible sensor that can wrap around power cables to precisely monitor electrical loads from household appliances to support grid operations.

Vera Bocharova at the Department of Energy’s Oak Ridge National Laboratory investigates the structure and dynamics of soft materials—polymer nanocomposites, polymer electrolytes and biological macromolecules—to advance materials and technologies for energy, medicine and other applications.