Filter News

Area of Research

- (-) Clean Energy (142)

- Advanced Manufacturing (22)

- Biology and Environment (16)

- Building Technologies (1)

- Computer Science (2)

- Electricity and Smart Grid (1)

- Energy Sciences (1)

- Functional Materials for Energy (2)

- Fusion and Fission (6)

- Fusion Energy (1)

- Isotopes (1)

- Materials (56)

- Materials for Computing (7)

- National Security (4)

- Neutron Science (12)

- Nuclear Science and Technology (4)

- Supercomputing (13)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (78)

- (-) Energy Storage (72)

- Advanced Reactors (6)

- Artificial Intelligence (8)

- Big Data (5)

- Bioenergy (26)

- Biology (11)

- Biomedical (6)

- Biotechnology (4)

- Buildings (36)

- Chemical Sciences (14)

- Clean Water (8)

- Climate Change (21)

- Composites (17)

- Computer Science (25)

- Coronavirus (12)

- Critical Materials (9)

- Cybersecurity (8)

- Decarbonization (33)

- Environment (54)

- Exascale Computing (2)

- Fossil Energy (2)

- Frontier (2)

- Fusion (1)

- Grid (40)

- High-Performance Computing (6)

- Hydropower (2)

- Isotopes (1)

- Machine Learning (7)

- Materials (35)

- Materials Science (26)

- Mathematics (2)

- Mercury (3)

- Microelectronics (1)

- Microscopy (8)

- Molten Salt (1)

- Nanotechnology (8)

- National Security (5)

- Net Zero (3)

- Neutron Science (11)

- Nuclear Energy (7)

- Partnerships (12)

- Physics (1)

- Polymers (11)

- Quantum Science (2)

- Renewable Energy (1)

- Security (6)

- Simulation (4)

- Space Exploration (3)

- Statistics (1)

- Summit (4)

- Sustainable Energy (69)

- Transformational Challenge Reactor (3)

- Transportation (65)

Media Contacts

Oak Ridge National Laboratory researchers have designed and additively manufactured a first-of-its-kind aluminum device that enhances the capture of carbon dioxide emitted from fossil fuel plants and other industrial processes.

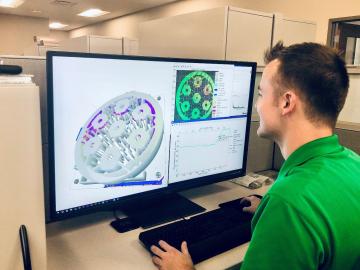

Oak Ridge National Laboratory researchers have developed artificial intelligence software for powder bed 3D printers that assesses the quality of parts in real time, without the need for expensive characterization equipment.

Joe Hagerman, ORNL research lead for buildings integration and controls, understands the impact building technology innovations can have during times of crisis. Over a decade ago, he found himself in the middle of one of the most devastating natural disasters of the century, Hurricane Katrina.

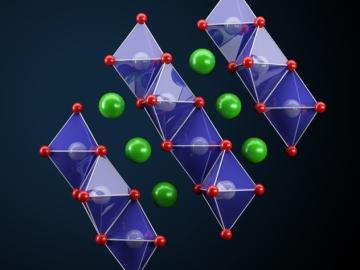

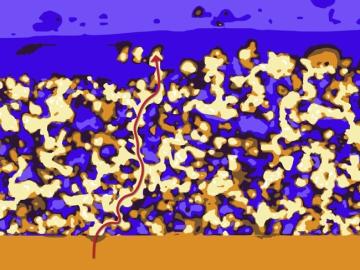

Oak Ridge National Laboratory scientists seeking the source of charge loss in lithium-ion batteries demonstrated that coupling a thin-film cathode with a solid electrolyte is a rapid way to determine the root cause.

Oak Ridge National Laboratory has licensed a novel method to 3D print components used in neutron instruments for scientific research to the ExOne Company, a leading maker of binder jet 3D printing technology.

Oak Ridge National Laboratory researchers have developed a thin film, highly conductive solid-state electrolyte made of a polymer and ceramic-based composite for lithium metal batteries.

Researchers at the Department of Energy’s Oak Ridge National Laboratory are refining their design of a 3D-printed nuclear reactor core, scaling up the additive manufacturing process necessary to build it, and developing methods

Researchers at Oak Ridge National Laboratory demonstrated a 20-kilowatt bi-directional wireless charging system on a UPS plug-in hybrid electric delivery truck, advancing the technology to a larger class of vehicles and enabling a new energy storage method for fleet owners and their facilities.

In the fight against the COVID-19 pandemic, it’s a race against the clock not only to find a vaccine but also to supply healthcare workers with life-saving equipment such as face shields, masks and test kits.

Suman Debnath, a researcher at ORNL, has been elevated to the grade of senior member of the Institute of Electrical and Electronics Engineers (IEEE).