Filter News

Area of Research

- (-) Clean Energy (67)

- Advanced Manufacturing (2)

- Biological Systems (1)

- Biology and Environment (62)

- Biology and Soft Matter (1)

- Computational Biology (2)

- Computational Engineering (1)

- Computer Science (4)

- Electricity and Smart Grid (1)

- Energy Frontier Research Centers (1)

- Functional Materials for Energy (1)

- Fusion and Fission (11)

- Fusion Energy (8)

- Isotopes (5)

- Materials (73)

- Materials for Computing (14)

- National Security (26)

- Neutron Science (33)

- Nuclear Science and Technology (15)

- Nuclear Systems Modeling, Simulation and Validation (1)

- Quantum information Science (9)

- Supercomputing (104)

- Transportation Systems (1)

News Topics

- (-) Advanced Reactors (6)

- (-) Biomedical (6)

- (-) Cybersecurity (8)

- (-) Decarbonization (33)

- (-) Microscopy (8)

- (-) Nanotechnology (8)

- (-) Quantum Science (2)

- (-) Simulation (4)

- (-) Summit (4)

- 3-D Printing/Advanced Manufacturing (78)

- Artificial Intelligence (8)

- Big Data (5)

- Bioenergy (26)

- Biology (11)

- Biotechnology (4)

- Buildings (36)

- Chemical Sciences (14)

- Clean Water (8)

- Climate Change (21)

- Composites (17)

- Computer Science (25)

- Coronavirus (12)

- Critical Materials (9)

- Energy Storage (72)

- Environment (54)

- Exascale Computing (2)

- Fossil Energy (2)

- Frontier (2)

- Fusion (1)

- Grid (40)

- High-Performance Computing (6)

- Hydropower (2)

- Isotopes (1)

- Machine Learning (7)

- Materials (35)

- Materials Science (26)

- Mathematics (2)

- Mercury (3)

- Microelectronics (1)

- Molten Salt (1)

- National Security (5)

- Net Zero (3)

- Neutron Science (11)

- Nuclear Energy (7)

- Partnerships (12)

- Physics (1)

- Polymers (11)

- Renewable Energy (1)

- Security (6)

- Space Exploration (3)

- Statistics (1)

- Sustainable Energy (69)

- Transformational Challenge Reactor (3)

- Transportation (65)

Media Contacts

As the United States transitions to clean energy, the country has an ambitious goal: cut carbon dioxide emissions in half by the year 2030, if not before. One of the solutions to help meet this challenge is found at ORNL as part of the Better Plants Program.

Four first-of-a-kind 3D-printed fuel assembly brackets, produced at the Department of Energy’s Manufacturing Demonstration Facility at Oak Ridge National Laboratory, have been installed and are now under routine operating

David Sholl has come to the U.S. Department of Energy’s Oak Ridge National Laboratory with a wealth of scientific expertise and a personal mission: hasten the development and deployment of decarbonization solutions for the nation’s energy system.

Through a consortium of Department of Energy national laboratories, ORNL scientists are applying their expertise to provide solutions that enable the commercialization of emission-free hydrogen fuel cell technology for heavy-duty

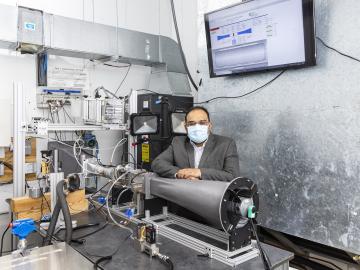

When Kashif Nawaz looks at a satellite map of the U.S., he sees millions of buildings that could hold a potential solution for the capture of carbon dioxide, a plentiful gas that can be harmful when excessive amounts are released into the atmosphere, raising the Earth’s temperature.

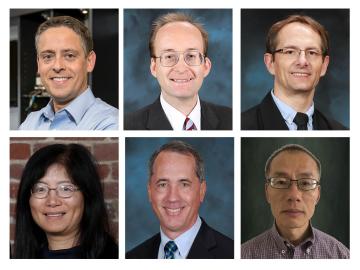

Six scientists at the Department of Energy’s Oak Ridge National Laboratory were named Battelle Distinguished Inventors, in recognition of obtaining 14 or more patents during their careers at the lab.

The University of Texas at San Antonio (UTSA) has formally launched the Cybersecurity Manufacturing Innovation Institute (CyManII), a $111 million public-private partnership.

The annual Director's Awards recognized four individuals and teams including awards for leadership in quantum simulation development and application on high-performance computing platforms, and revolutionary advancements in the area of microbial

Seven ORNL scientists have been named among the 2020 Highly Cited Researchers list, according to Clarivate, a data analytics firm that specializes in scientific and academic research.

The Transformational Challenge Reactor, or TCR, a microreactor built using 3D printing and other new advanced technologies, could be operational by 2024.