Katy Bradford: Cassette approach offers compelling construction solution

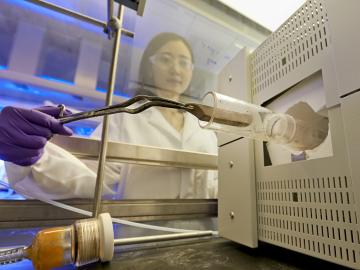

As a boy growing up in China, Xiaobing Liu knew all about Oak Ridge and the World War II Manhattan Project. He had no idea that he would one day work at DOE’s Oak Ridge National Laboratory, the Secret City’s successor. Liu is a lead researcher in geothermal heat pump (GHP) techn...

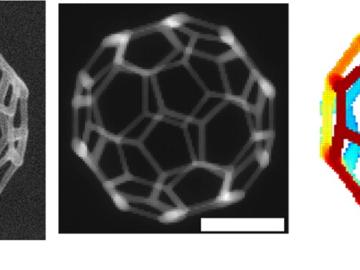

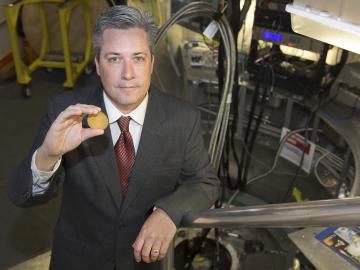

The lighter wand for your gas BBQ, a submarine’s sonar device and the ultrasound machine at your doctor’s office all rely on piezoelectric materials, which turn mechanical stress into electrical energy, and vice versa. In 1997, researchers developed piezoelectric...

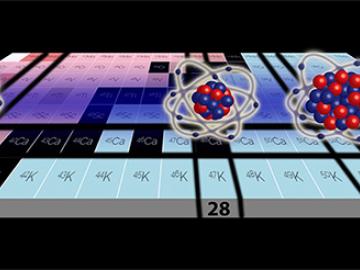

The US Department of Energy announced today that it will invest $16 million over the next four years to accelerate the design of new materials through use of supercomputers.