Filter News

Area of Research

- (-) Fuel Cycle Science and Technology (3)

- (-) Materials (433)

- Advanced Manufacturing (34)

- Biological Systems (18)

- Biology and Environment (177)

- Biology and Soft Matter (5)

- Building Technologies (12)

- Chemical and Engineering Materials (4)

- Chemistry and Physics at Interfaces (11)

- Clean Energy (522)

- Climate and Environmental Systems (14)

- Computational Biology (6)

- Computational Chemistry (5)

- Computational Engineering (5)

- Computer Science (19)

- Data (1)

- Earth Sciences (1)

- Electricity and Smart Grid (3)

- Energy Frontier Research Centers (14)

- Energy Sciences (5)

- Fossil Energy (3)

- Functional Materials for Energy (16)

- Fusion and Fission (54)

- Fusion Energy (17)

- Geographic Information Science and Technology (3)

- Isotope Development and Production (3)

- Isotopes (35)

- Materials Characterization (2)

- Materials for Computing (36)

- Materials Synthesis from Atoms to Systems (13)

- Materials Under Extremes (12)

- Mathematics (1)

- National Security (79)

- Neutron Data Analysis and Visualization (4)

- Neutron Science (190)

- Nuclear Science and Technology (74)

- Nuclear Systems Modeling, Simulation and Validation (3)

- Nuclear Systems Technology (1)

- Quantum Condensed Matter (4)

- Quantum information Science (9)

- Reactor Technology (1)

- Renewable Energy (4)

- Sensors and Controls (5)

- Supercomputing (311)

- Transportation Systems (11)

News Type

News Topics

- 3-D Printing/Advanced Manufacturing (23)

- Advanced Reactors (4)

- Artificial Intelligence (9)

- Big Data (2)

- Bioenergy (11)

- Biology (4)

- Biomedical (7)

- Buildings (5)

- Chemical Sciences (32)

- Clean Water (3)

- Climate Change (5)

- Composites (9)

- Computer Science (17)

- Coronavirus (4)

- Critical Materials (13)

- Cybersecurity (4)

- Decarbonization (7)

- Energy Storage (34)

- Environment (15)

- Exascale Computing (2)

- Frontier (3)

- Fusion (7)

- Grid (5)

- High-Performance Computing (4)

- Irradiation (1)

- Isotopes (13)

- ITER (1)

- Machine Learning (5)

- Materials (73)

- Materials Science (78)

- Mathematics (1)

- Microscopy (27)

- Molten Salt (3)

- Nanotechnology (39)

- National Security (4)

- Net Zero (1)

- Neutron Science (33)

- Nuclear Energy (17)

- Partnerships (11)

- Physics (29)

- Polymers (17)

- Quantum Computing (3)

- Quantum Science (11)

- Renewable Energy (1)

- Security (2)

- Simulation (1)

- Space Exploration (2)

- Summit (2)

- Sustainable Energy (13)

- Transformational Challenge Reactor (3)

- Transportation (14)

Media Contacts

Oak Ridge National Laboratory has successfully developed and tested a novel sand casting technique to quickly design complex patterns to fabricate components for industry partner Emrgy Hydro, makers of hydropower devices designed to generate electricity from slow or shallow water flo...

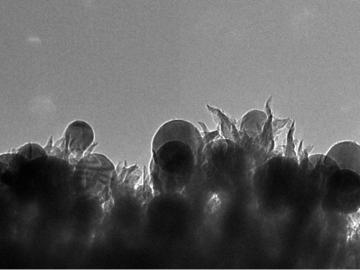

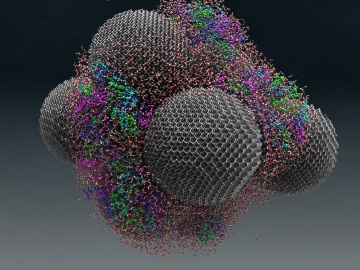

Barely wider than a strand of human DNA, magnetic nanoparticles—such as those made from iron and platinum atoms—are promising materials for next-generation recording and storage devices like hard drives. Building these devices from nanoparticles should increase storage capaci...

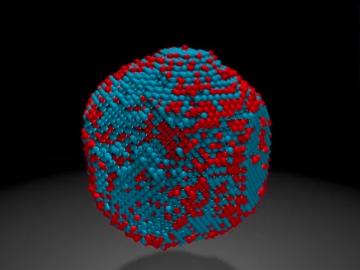

Researchers at the Department of Energy’s Oak Ridge National Laboratory have demonstrated that permanent magnets produced by additive manufacturing can outperform bonded magnets made using traditional techniques while conserving critical materials. Scientists fabric...